Angle limiting force value transmission device with protection function

A technology of protection function and transmission device, applied in the direction of transmission device, belt/chain/gear, mechanical equipment, etc., can solve the problems of secondary damage, unobservable belt, eccentric wear of tensioning mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

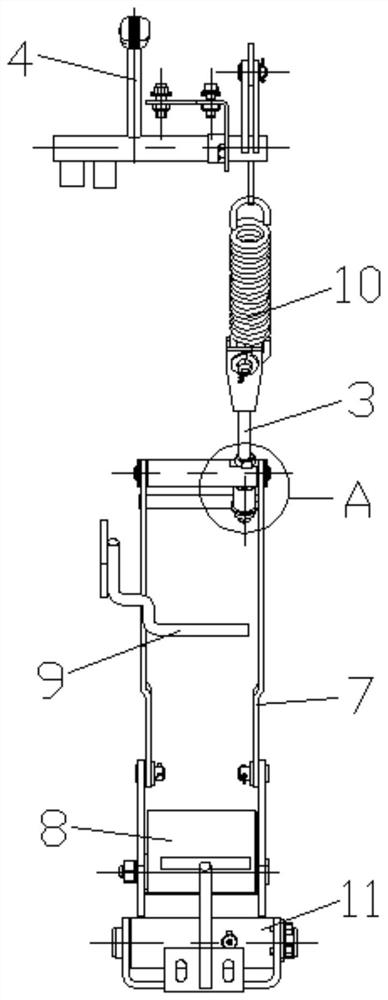

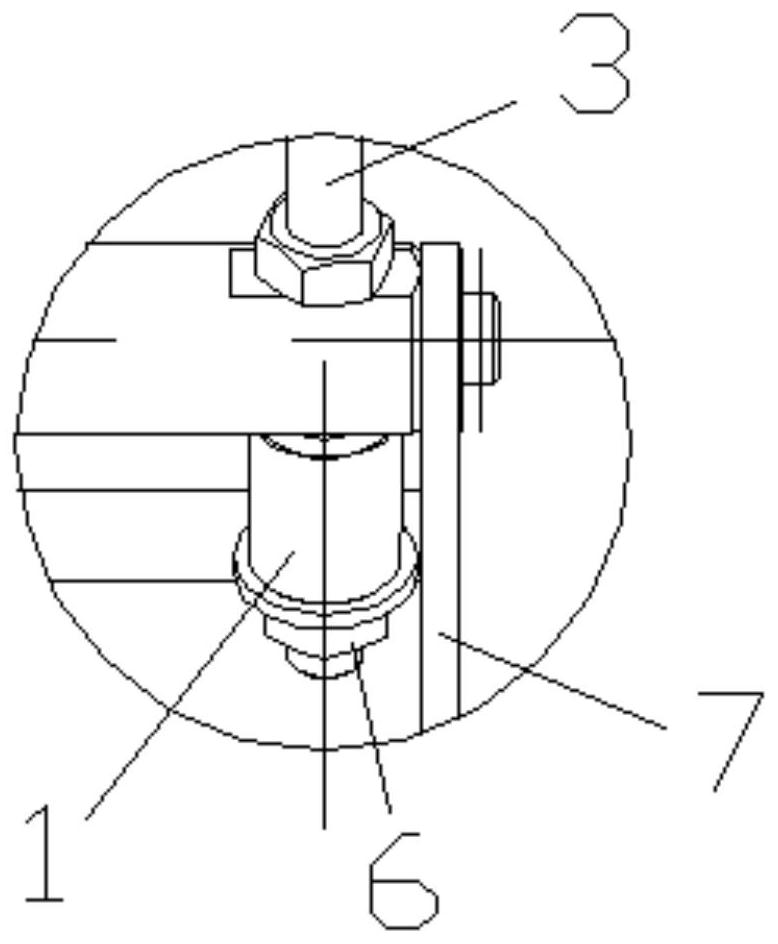

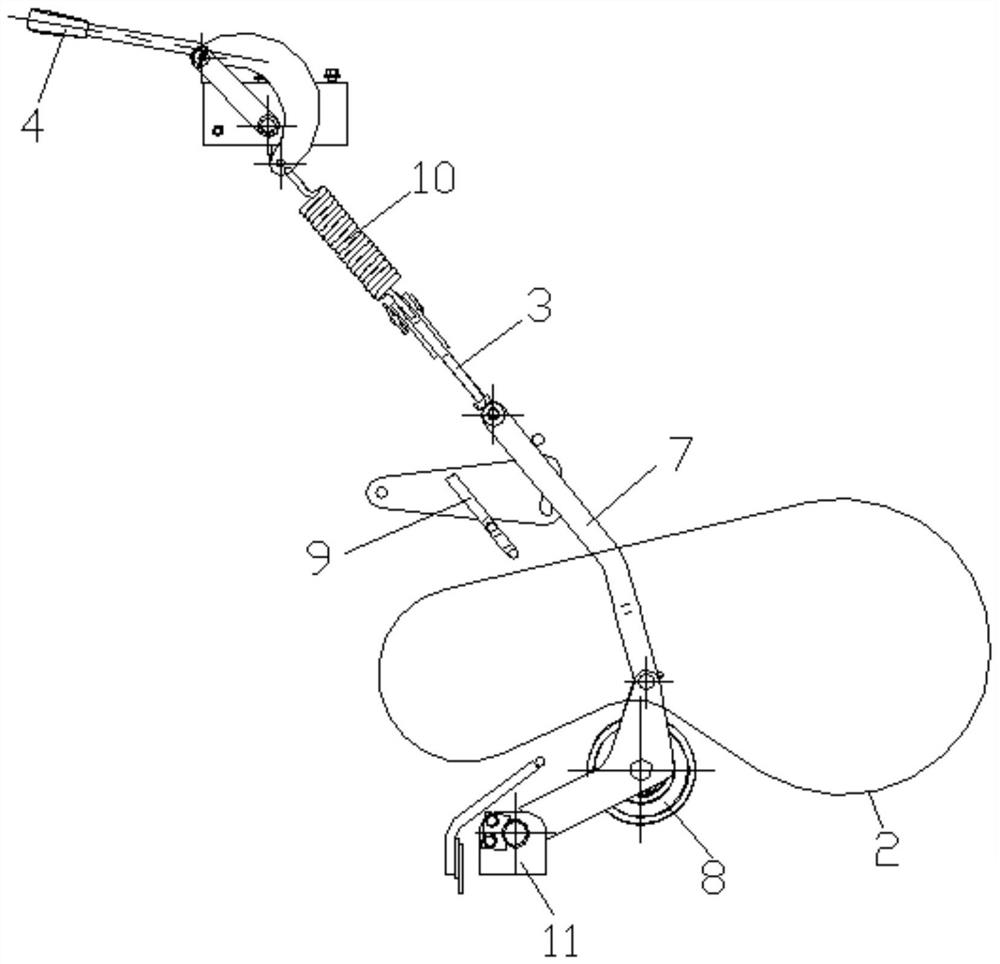

[0039] On the basis of the above structure, in this embodiment, the protective member 1 is a protective tube with both ends open. The protective tube is coaxially slidably sleeved on the lower end of the pull rod 3. The structure is simple and the design is reasonable. The protective tube and the pull rod 3 When the tension surface of belt 1 is tilted, the protective tube will break to release the tension mechanism, so that belt 1 can return to the state where the tension surface is parallel to protect belt 2.

Embodiment 2

[0041] On the basis of Embodiment 1, in this embodiment, at least one end of the protective tube is provided with at least one pre-slit 5 , which has a simple structure and reasonable design, so that the protective tube is easy to break when twisted, thereby better protecting the belt 2 .

Embodiment 3

[0043] On the basis of Embodiment 2, preferably, in this embodiment, the two ends of the protection tube are respectively provided with pre-slits 5, and the two pre-slits 5 are arranged opposite to each other, so that the protection tube is easier to break and can better protect the belt. 2.

[0044] In addition to the above-mentioned embodiments, one or more pre-slits 5 can also be set at any one end of the protection tube, for example, only one pre-slit 5 can be set at any one end of the protection tube, or two can also be set at any one end of the protection tube. Even a plurality of pre-slits 5, when the number of pre-slits 5 is two, preferably oppositely arranged, so as to facilitate rapid rupture of the protective tube; at the same time, multiple pre-slits 5 can also be set at both ends of the protective tube, and the two ends of the protective tube The number of the pre-slits 5 at the end can be the same or different, and when they are the same, they are preferably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com