Cast-in-place floor slab quality control device and construction method thereof

A technology for control devices and cast-in-place floor slabs, which is applied in construction, building structure, and processing of building materials, etc., and can solve problems that affect project quality and slab surface leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

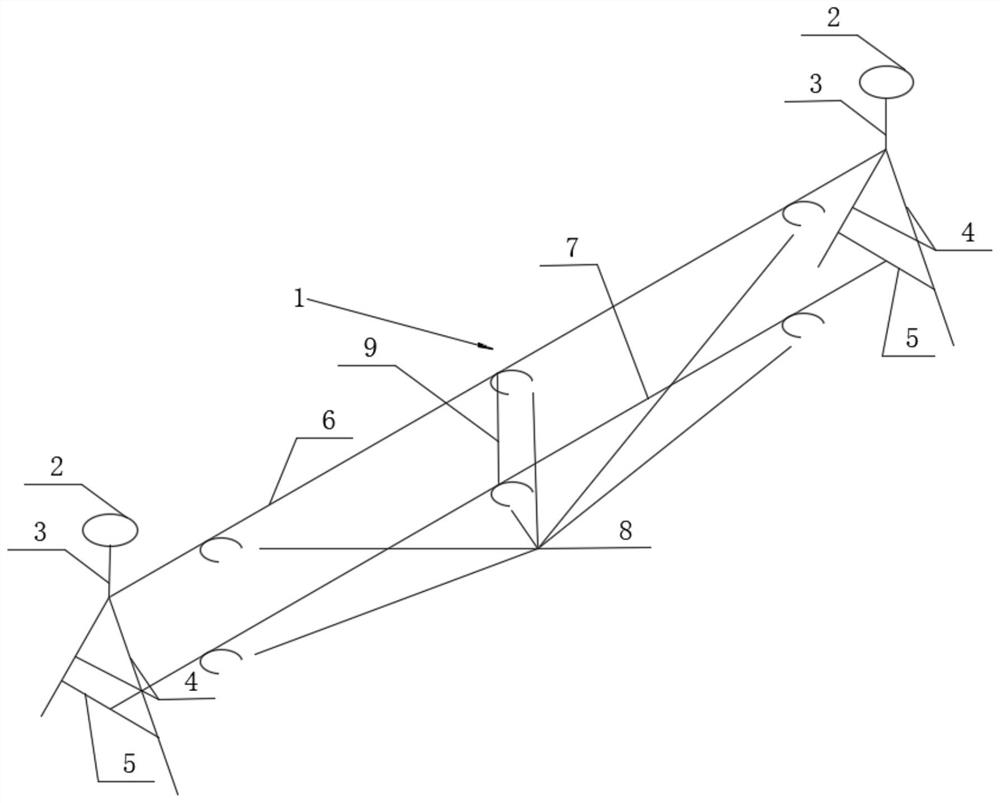

[0029] The cast-in-place floor slab quality control device in this embodiment can be used to fix the negative reinforcement bend anchor section of the floor slab support, and can also be used to control the thickness of the floor slab.

[0030] Specifically, such as figure 1 As shown, the cast-in-place floor quality control device 1 of the present embodiment includes a floor thickness console seat 2, a connecting vertical bar 3, a support oblique bar 4, a support cross bar 5, an upper cross bar 6, a lower cross bar 7, and a floor support support. Rib fixing ring 8 and support vertical bar 9.

[0031] Wherein, the tops of the two support slanting bars 4 are connected together at a predetermined angle, and the middle and lower parts of the two support slanting bars 4 are provided with a support cross bar 5 to form a base frame for installing other components.

[0032] The two ends of the upper cross bar 6 are respectively fixedly installed on the tops of the base frames on both...

Embodiment 2

[0044] The difference between the cast-in-place slab quality control device of the present embodiment and embodiment 1 is:

[0045] The floor thickness control seat and the connecting vertical rod are omitted, the structure is simplified, and the fixing of the negative reinforcement bending anchor section of the floor support is realized, which meets the needs of different application occasions.

[0046] Other structures can refer to Embodiment 1.

Embodiment 3

[0048] The difference between the cast-in-place slab quality control device of the present embodiment and embodiment 1 is:

[0049] Omit the connecting vertical bar, simplify the structure, that is, the floor thickness control seat is directly fixed on the top of the base frame, changing the height of the base frame, can also realize the fixing of the negative reinforcement bending anchor section of the floor support and the control of the floor thickness to meet different applications The needs of the occasion.

[0050] Other structures can refer to Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com