Steel-concrete combined section structure of large-span hybrid combined beam of high-speed railway

A steel-concrete combination, high-speed railway technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of sudden change in stiffness of the joint section, uneven force transmission at the joint section, complex force, etc., and achieve smooth transition of stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

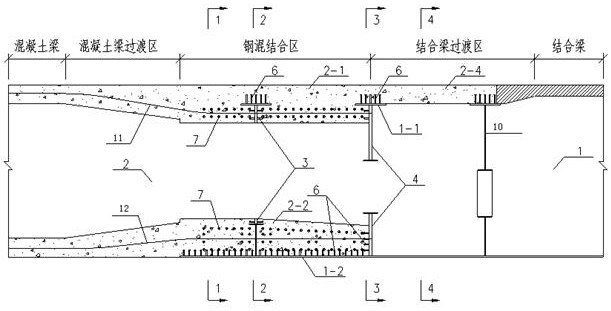

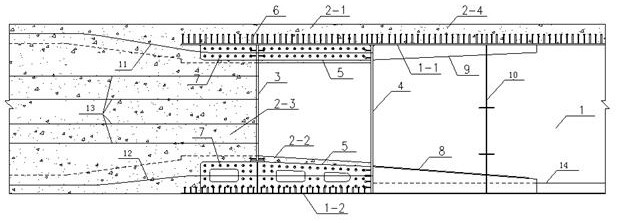

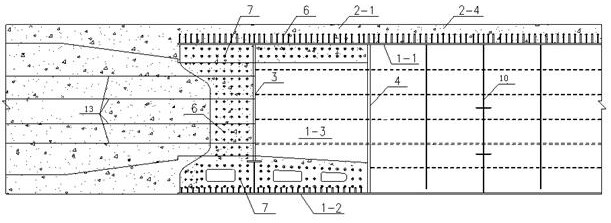

[0041] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0042] Such as Figure 1~7 As shown, a steel-concrete combined section structure of a large-span hybrid combined beam for a high-speed railway includes an open steel box girder 1, a concrete bridge deck 2-4 and a concrete box girder 2, and the steel girder floor at the bottom of the open steel box girder 1 The free ends of 1-2 form the steel beam nozzle plate 1-5, the steel beam bottom plate 1-2, the steel beam nozzle plate 1-5 outsourcing the concrete box girder 2, the steel beam middle web of the open steel box girder 1 1-3 and steel girder side webs 1-4 are embedded in concrete box girder 2 to realize the combination of open steel box girder 1 and concrete box girder 2.

[0043] A steel beam top plate 1-1 is arranged on the top of the steel beam middle web 1-3 and the steel beam side web 1-4.

[0044] The concrete bridge deck 2-4 is combined with the open st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com