Fixed joint of double-wall hollow pier column and steel bridge and construction method

A technology for hollow piers and steel bridges, applied in bridge construction, bridges, buildings, etc., to achieve the effects of ensuring node safety, enhancing ductility, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

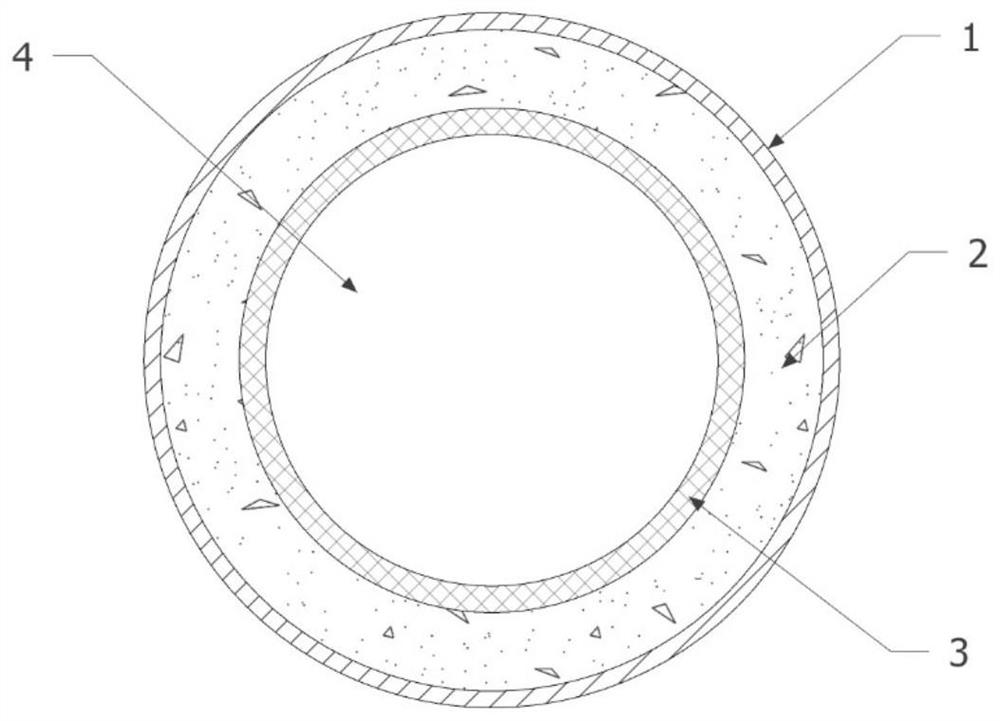

[0040] See attached Figure 2a , 3a , 4a, 5a. in, Figure 2a for figure 1 Middle A-A sectional view, Figure 3a is the B-B sectional view, Figure 4a is the C-C sectional view, Figure 5a It is a D-D sectional view.

[0041] In this embodiment, the composite pipe-concrete-steel pipe double-walled hollow pier column and the steel bridge fixed joint include a composite material pipe-concrete-steel pipe double-walled hollow pier section (referred to as the hollow section), a composite material pipe-concrete-steel pipe double-walled hollow pier Tube-concrete-steel tube double-walled solid pier section (solid section), composite tube-concrete-steel tube double-walled solid pier section (reinforced section) with steel pipe thickened, steel tube concrete transition section with longitudinal stiffeners (transition section ); a steel inner partition is set between the hollow section and the solid section to block the concrete in the steel pipe of the solid section, and the steel...

Embodiment 2

[0055] See attached Figure 2b , 3b , 4b, 5b. in, Figure 2b is A-A sectional view, Figure 3b is the B-B sectional view, Figure 4b is the C-C sectional view, Figure 5b It is a D-D sectional view.

[0056] In this embodiment, the cross-sectional contours of the outer composite pipes of the hollow section, solid section, and reinforced section are all circular, with an inner diameter of 800 mm and a thickness of 12 mm; the inner steel pipes of the hollow section, solid section, reinforced section, and transition section They are all single-cavity steel pipes, and their cross-sectional contours are square, with an outer length of 420mm; the thickness of the steel pipes in the hollow section and the solid section is the same, both 16mm; the thickness of the steel pipes in the reinforced section and the transition section is 20mm.

[0057] In this embodiment, the steel inner partition (see Figure 3b The three-dimensional schematic diagram in), the steel inner ring plate ...

Embodiment 3

[0063] See attached Figure 2c , 3c , 4c, 5c. in, Figure 2c is A-A sectional view, Figure 3c is the B-B sectional view, Figure 4c is the C-C sectional view, Figure 5c It is a D-D sectional view.

[0064] In this embodiment, the cross-sectional contours of the outer composite pipes of the hollow section, the solid section, and the reinforced section are all square, with an inner side length of 700mm and a thickness of 12mm; the inner steel pipes of the hollow section, the solid section, the reinforced section, and the conversion section They are all single-cavity steel pipes, and their cross-sectional contours are square, with an outer length of 420mm; the thickness of the steel pipes in the hollow section and the solid section is the same, both 16mm; the thickness of the steel pipes in the reinforced section and the transition section is 20mm.

[0065] In this embodiment, the steel inner partition (see Figure 3c The three-dimensional schematic diagram in), the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com