Moisture-proof and corrosion-proof corrugated paper production process and device

A production process and production device technology, applied in the field of moisture-proof and anti-corrosion corrugated paper production process and its device, can solve the problems of fiber agglomeration, poor strength, rough corrugated paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

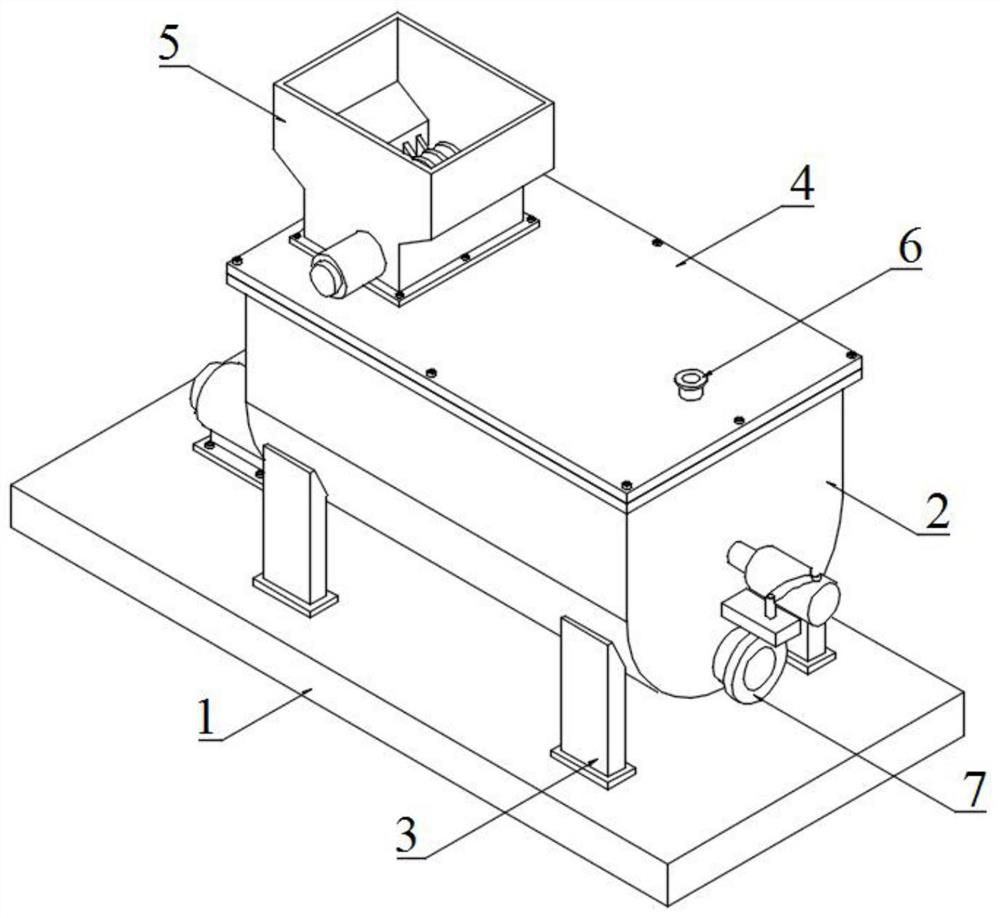

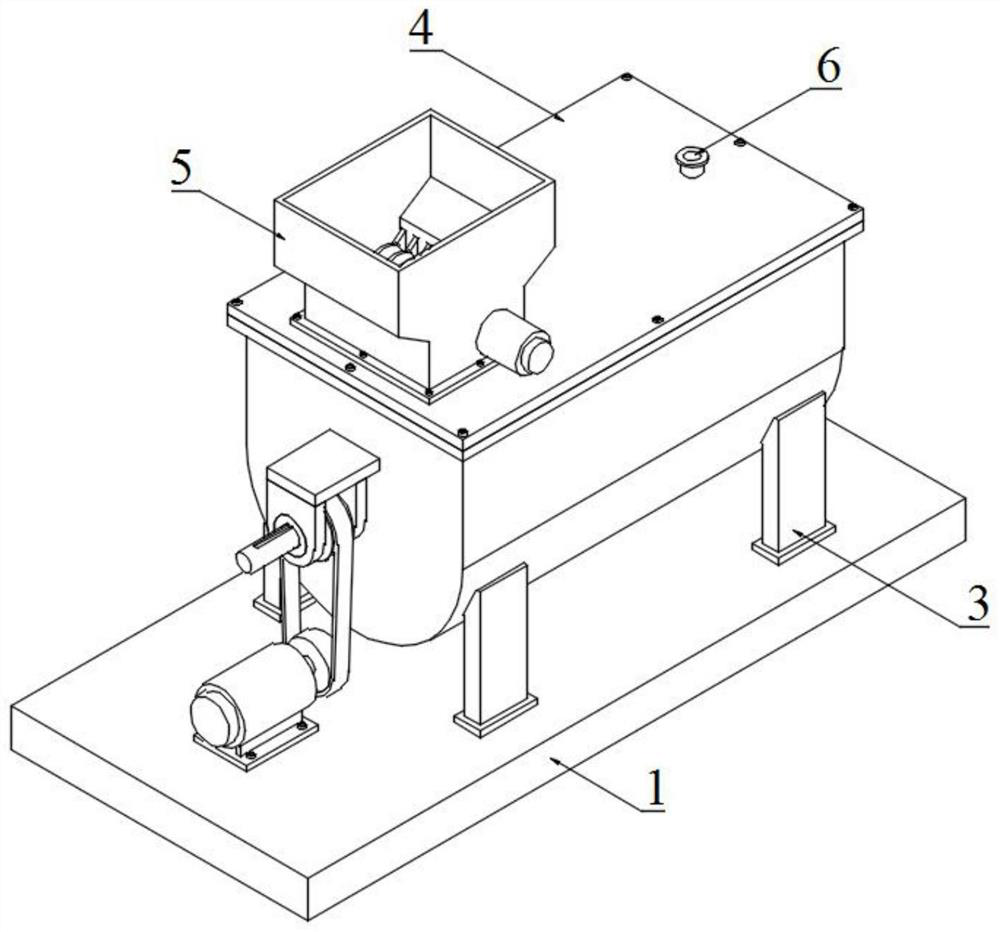

Image

Examples

Embodiment 1

[0055] The preparation method of corrugated base paper comprises the following steps:

[0056] S1. Beat waste paper to obtain long-fiber pulp, short-fiber pulp and broke pulp, and configure corrugated base paper surface layer raw material pulp and bottom raw material pulp;

[0057] S2. Adding an internal sizing agent to the corrugated base paper surface layer raw material pulp and the bottom layer raw material pulp to perform internal sizing treatment of the slurry;

[0058] S3, the surface layer raw material pulp and the bottom raw material pulp after the internal sizing treatment are subjected to netting, pressing and drying to obtain a base paper embryo;

[0059] S4, uniformly coating a surface sizing agent on the surface of the raw paper base, and then drying the base paper base after surface sizing to obtain a corrugated base paper.

[0060] In step S2, the internal sizing agent is an alkaline sizing agent AKD, and the amount of the internal sizing agent relative to the ...

Embodiment 2

[0075] The preparation method of corrugated base paper comprises the following steps:

[0076] S1. Beat waste paper to obtain long-fiber pulp, short-fiber pulp and broke pulp, and configure corrugated base paper surface layer raw material pulp and bottom raw material pulp;

[0077] S2. Adding an internal sizing agent to the corrugated base paper surface layer raw material pulp and the bottom layer raw material pulp to perform internal sizing treatment of the slurry;

[0078] S3, the surface layer raw material pulp and the bottom raw material pulp after the internal sizing treatment are subjected to netting, pressing and drying to obtain a base paper embryo;

[0079] S4, uniformly coating a surface sizing agent on the surface of the raw paper base, and then drying the base paper base after surface sizing to obtain a corrugated base paper.

[0080] In step S2, the internal sizing agent is an alkaline sizing agent AKD, and the amount of the internal sizing agent relative to the ...

Embodiment 3

[0095] The preparation method of corrugated base paper comprises the following steps:

[0096] S1. Beat waste paper to obtain long-fiber pulp, short-fiber pulp and broke pulp, and configure corrugated base paper surface layer raw material pulp and bottom raw material pulp;

[0097] S2. Adding an internal sizing agent to the corrugated base paper surface layer raw material pulp and the bottom layer raw material pulp to perform internal sizing treatment of the slurry;

[0098] S3, the surface layer raw material pulp and the bottom raw material pulp after the internal sizing treatment are subjected to netting, pressing and drying to obtain a base paper embryo;

[0099] S4, uniformly coating a surface sizing agent on the surface of the raw paper base, and then drying the base paper base after surface sizing to obtain a corrugated base paper.

[0100] In step S2, the internal sizing agent is an alkaline sizing agent AKD, and the amount of the internal sizing agent relative to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com