GCL method polycrystalline silicon production whole process comprehensive water-saving production system and method

A method of polysilicon and production system, which can be used in general water supply conservation, chemical instruments and methods, filtration treatment, etc., and can solve problems such as insufficient municipal supporting facilities and lack of water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with specific embodiments.

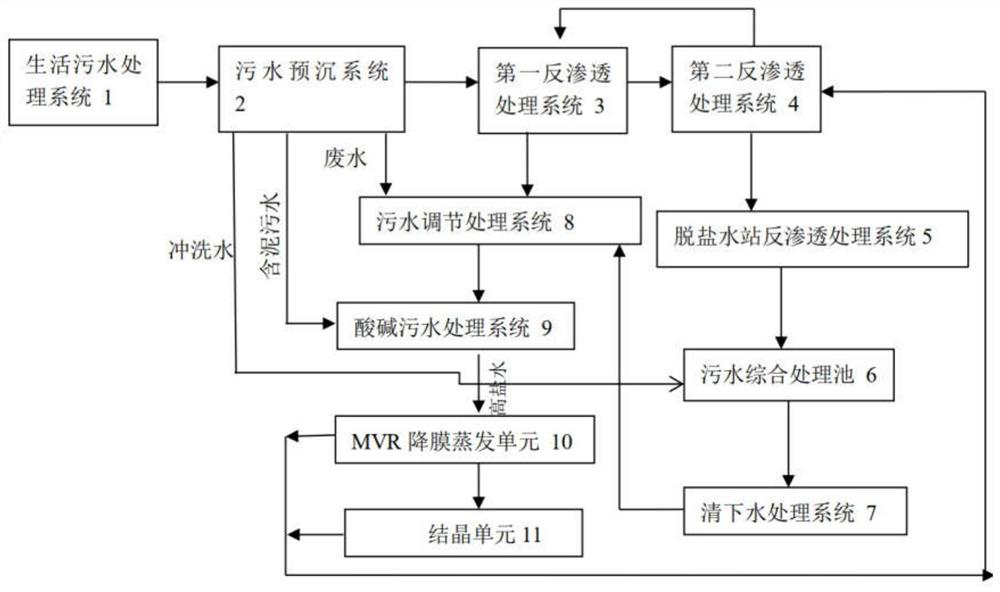

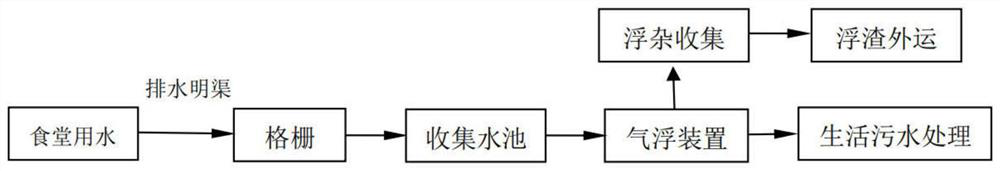

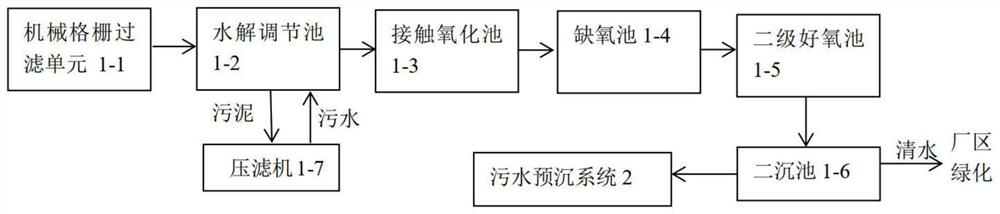

[0055] The invention provides a comprehensive water-saving production system and method for the whole process of polysilicon production, which comprehensively optimizes the water and drainage of domestic and production systems, and systematically balances all plans for water and drainage treatment of polysilicon enterprises. The clean water, desalinated water, reclaimed water, etc. used by the device finally go to the sewage station, and the high-salt sewage passes through flocculation, sedimentation, air flotation, multi-media filtration, and MVR evaporation crystallization system, and the high-quality reused water produced is used as the intake of the desalinated water station. Water and solid miscellaneous salts produced by the crystallization system are transported outside for disposal. The sewage is reused to the maximum extent, and the comprehensive utilizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com