Cement conveying equipment based on quantitative conveying and capable of preventing cement ash from raising dust

A technology for conveying equipment and cement ash, which is applied to conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as harming the health of workers, easy dusting of cement dust, and inability to ensure long-distance conveying and quantitative conveying of cement at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

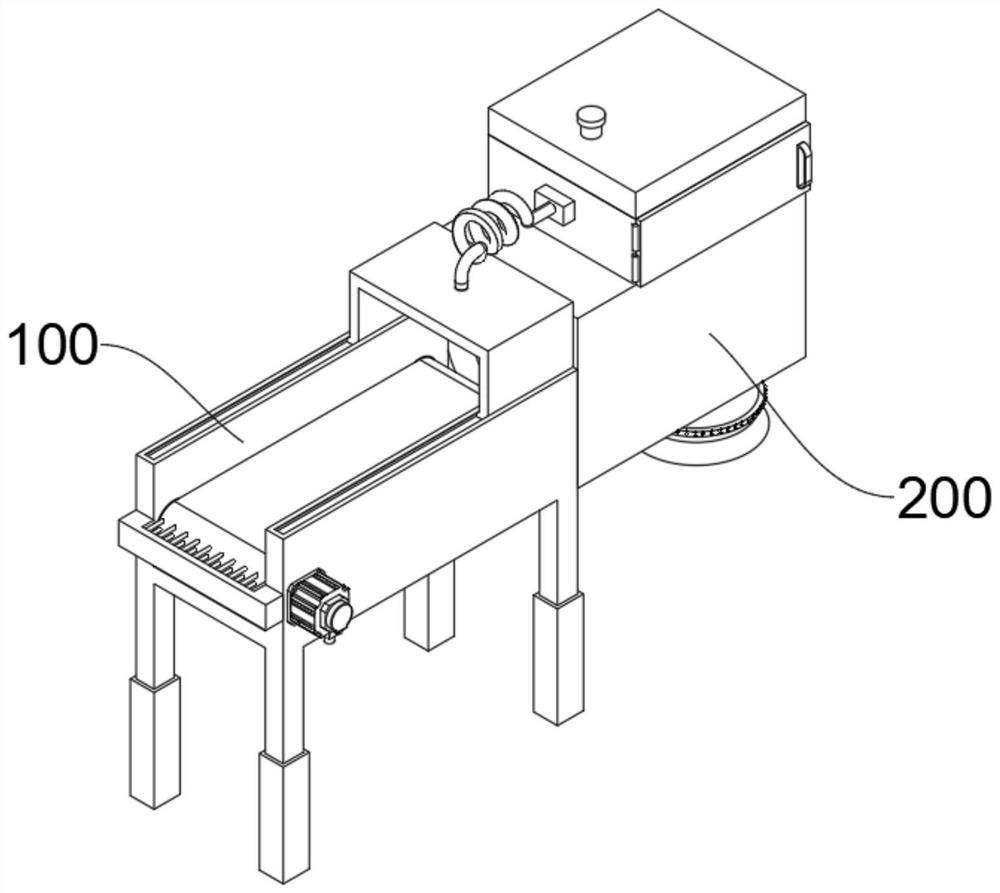

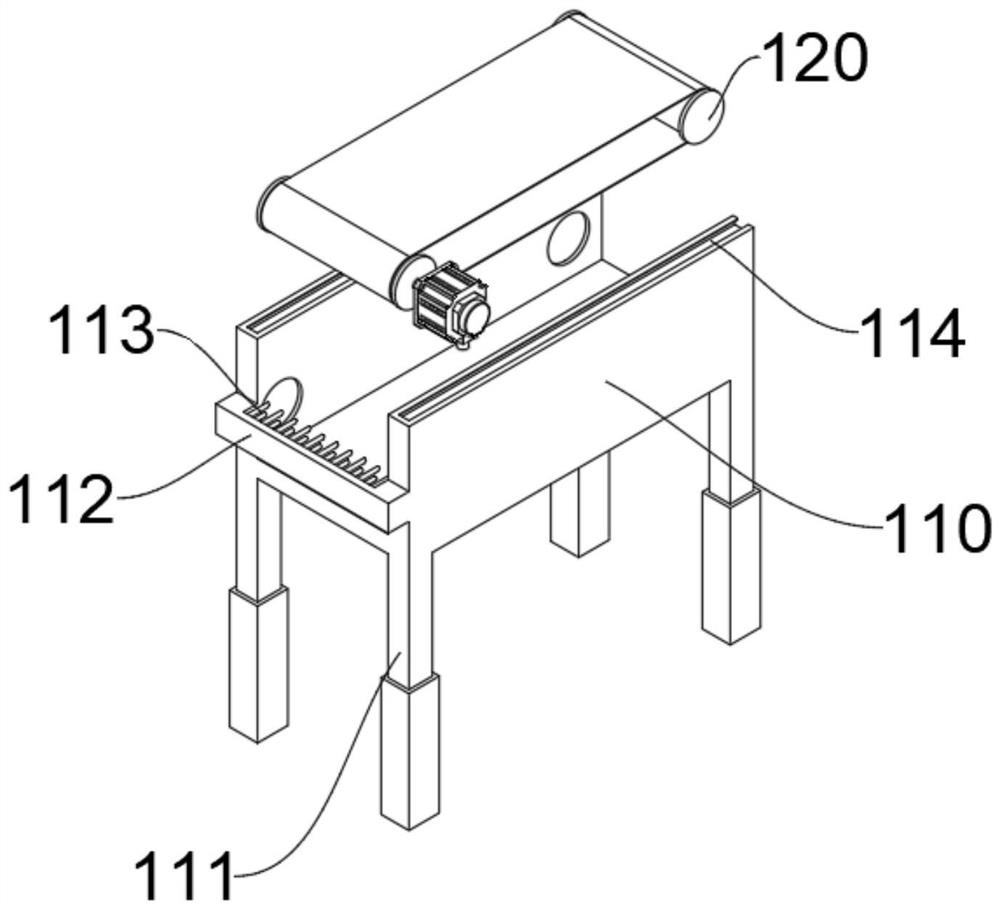

[0049] see Figure 1-Figure 13 As shown, this embodiment provides cement delivery equipment based on quantitative delivery that can prevent cement ash from raising dust, including a conveyor 100 and a cement delivery mechanism 200 connected to the end of the conveyor 100. The cement delivery mechanism 200 at least includes:

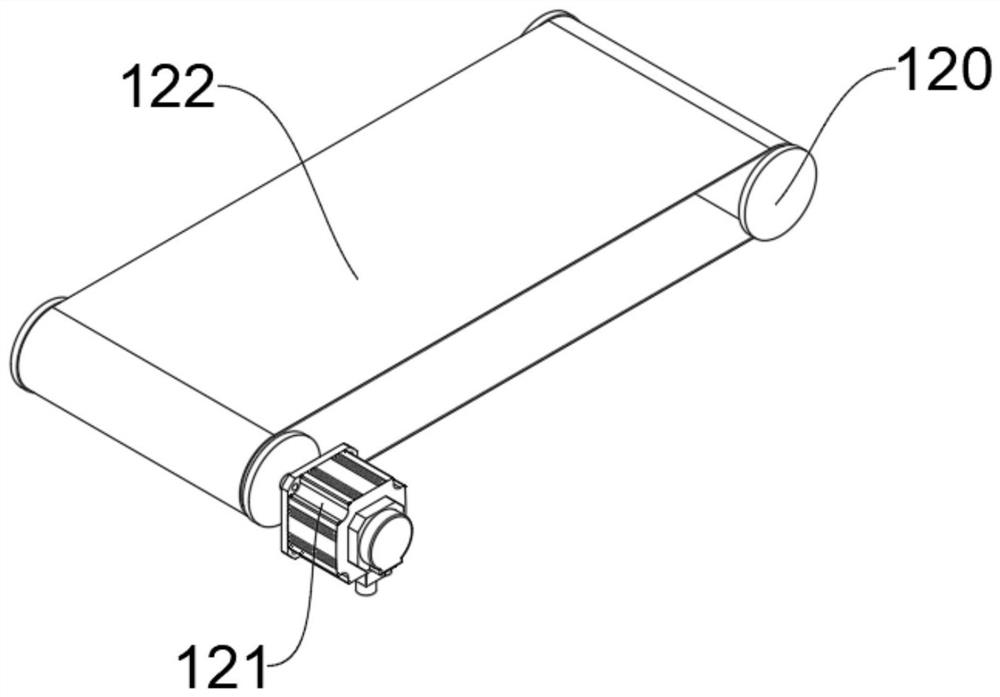

[0050] Quantitative conveying device 210, quantitative conveying device 210 comprises conveying box 211, conveying box 211 is provided with discharge port 214 away from the outer wall of conveyor 100, makes the cement inside conveying case 211 flow out from discharge port 214 inside, facilitates follow-up use, The end of the delivery box 211 is connected to the end of the conveyor 100, and the inside of the delivery box 211 is rotated to be provided with a screw conveyor rod 212, and the end of the screw conveyor rod 212 is rotated and stretched out. , to make it work, the output shaft of the rotating motor 213 drives the screw conveying rod 212 to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com