a polishing pad

A polishing pad and a range of technology, applied in the field of polishing pads, can solve the problems of uneven grinding rate depression and erosion, polishing rate reduction, unevenness, etc., and achieve the effects of good grinding uniformity, good grinding rate, and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

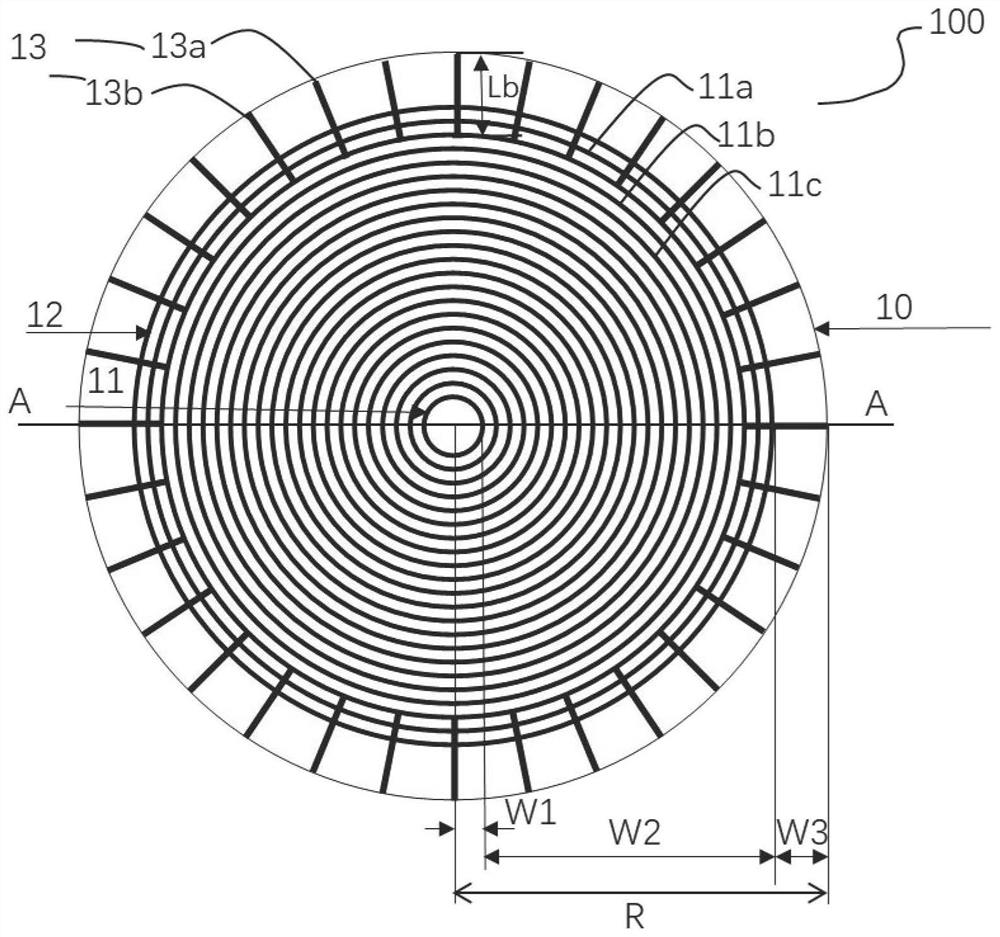

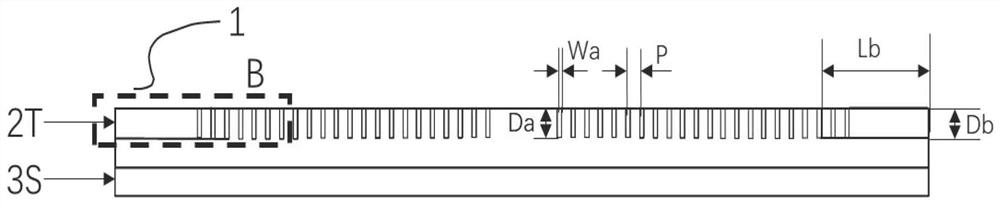

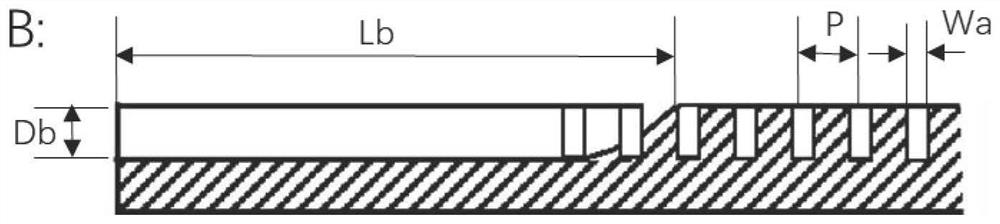

[0059] figure 1 is a plan view schematically showing a polishing pad according to a preferred embodiment of the present invention. refer to figure 1 , the polishing pad of the present invention is suitable for polishing or planarizing at least one of semiconductor, optical and magnetic substrates. The polishing pad includes an abrasive layer 100 . The grinding layer 100 includes at least two concentric circular grooves. The concentric circular grooves in the present invention refer to annular grooves with a common center but unequal radii. Define the innermost concentric circle groove as the first concentric circle 11, and the outermost concentric circle groove as the second concentric circle 12; the first concentric circle 11 and the second concentric circle 12 define multiple grinding areas, defined in the radial direction Above, the distance between the innermost side of the first concentric circle 11 and the center of the grinding layer is W1, the distance between the o...

Embodiment approach 2

[0097] As another preferred embodiment of the present invention, similar to Embodiment 1, in combination with the groove pattern of the present invention, the properties of the abrasive layer and buffer layer of the polishing pad are more preferably limited.

[0098] As a preferred embodiment of the present invention, the hardness range of the grinding layer is 50-67D, and the density range is 0.66-0.87g / cm 3 , the range of compression rate is 0.001-0.06. The hardness range of the buffer layer is 59-86A, and the density range is 0.25-0.4g / cm 3 , the range of compression ratio is 0.02-0.12.

[0099] More preferably, the hardness difference between the grinding layer and the buffer layer is in the range of 29-45.5D, and the density difference is in the range of 0.32-0.46g / cm 3 , the range of the absolute value of the compressibility difference is 0.025-0.089.

[0100] More preferably, the abrasive layer has a hardness in the range of 54-64D and a density in the range of 0.67-...

Embodiment approach 3

[0113] The third groove of the present invention is a linear groove. For example, the third grooves of Embodiments 1 to 2 are all linear. As another preferred embodiment of the present invention, the third groove of the third grinding area of the polishing pad The grooves can also be curved. Combined with the groove pattern of the present invention, the properties of the abrasive layer and buffer layer of the polishing pad are more preferably defined, which are the same as those in the first and second embodiments, and will not be described again.

[0114] further reference Figure 5 , the polishing pad includes an abrasive layer 300, and the abrasive layer 300 is in direct contact with the material to be abrasive. The grinding layer 300 includes at least two concentric grooves, the first concentric circle and the second concentric circle define a plurality of grinding areas; the size and parameter range of the first grinding area and the second grinding area in the third e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com