Manufacturing mould for assembly type turnover support and construction method

A prefabricated and moulded technology, applied in manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of uncontrollable welding deformation, unable to guarantee the perpendicularity between flange and pipe section, unable to guarantee the connection accuracy of connecting holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

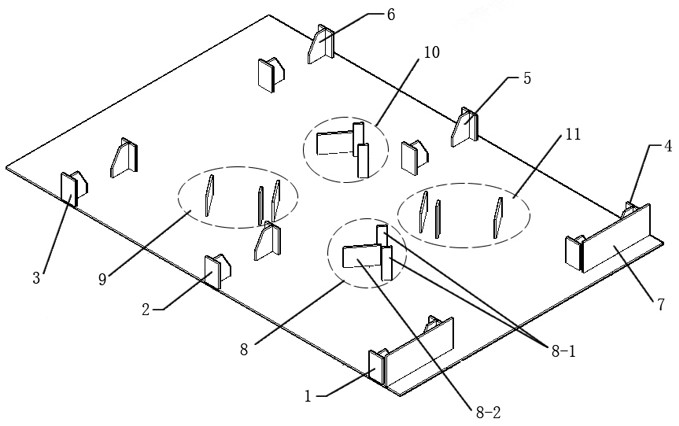

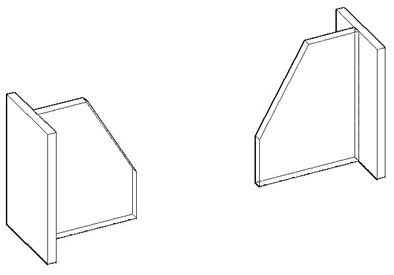

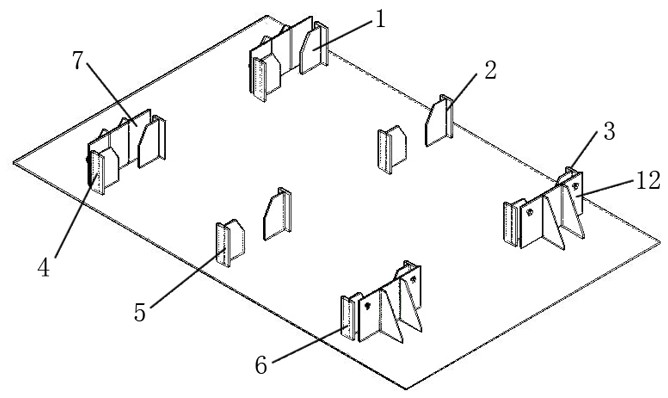

[0044] see Figure 1 to Figure 1 As shown in 1, a kind of assembly-type turnover support manufacturing mold provided by the present invention includes a single support body mold table, a flange assembly mold table, a flange welding mold table and a side support mold table, wherein:

[0045] Monolithic support phantom table: such as figure 1, 2, including the base plate, the surface of the base plate is provided with positioning block A 1, positioning block B 2 and positioning block C 3 for the positioning of the left support tube; positioning block D 4, positioning block E 5 and positioning block for the positioning of the right support tube Block F6; positioning plate M1 8, positioning plate M2 10 for the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com