Complex product operation, maintenance and manufacturing integrated general model based on digital twinning

A complex product, twinning technology, applied in the scientific field of intelligent operation and maintenance and manufacturing, can solve problems such as the inability of timely communication between operation and maintenance and manufacturing information, and less consideration of the manufacturing information of the manufacturer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

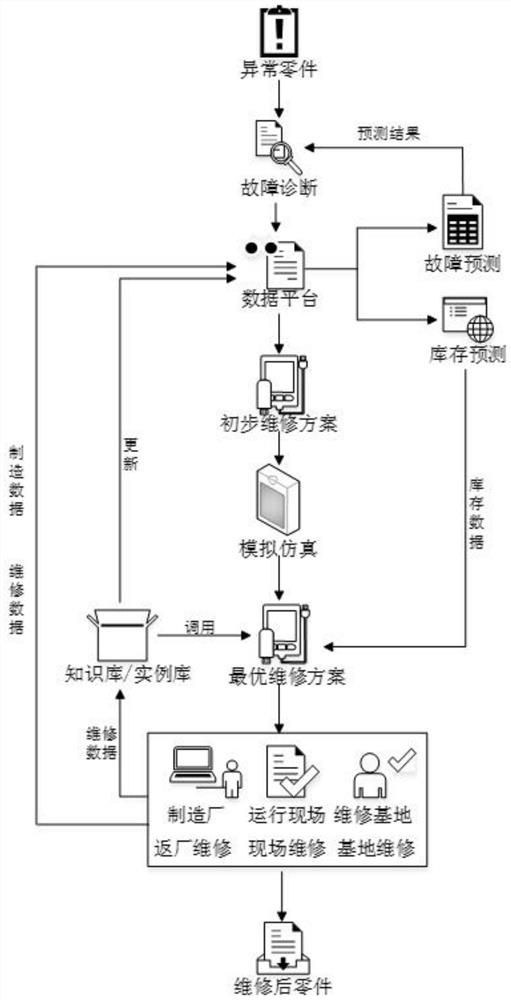

[0057] Such as figure 1 As shown, the overall model of complex product operation and maintenance and manufacturing integration based on digital twins, including operation and maintenance system module, virtual maintenance unit module, maintenance center module, manufacturing plant module and data platform module, the manufacturing plant module and maintenance center module constitute The physical space of the twin system, the virtual maintenance unit module constitutes the virtual space of the twin system, the operation and maintenance system module, the virtual maintenance unit module, the manufacturing plant module and the maintenance center module respectively transmit the service data, simulation data, manufacturing data and maintenance data To the data platform module, and receive the feedback of the data platform module; the data platform module will collect the data information, after the data fusion processing unit performs data fusion processing, it will interact with ...

Embodiment 2

[0068] Such as figure 2 As shown, a digital twin-based operation mode of complex product operation and maintenance and manufacturing integration overall model, including:

[0069] 1) When an abnormality occurs during the operation of a complex product, the operation and maintenance personnel need to analyze the cause of the abnormality in the operation and maintenance system, obtain the repair information data of the parts that need to be repaired after fault diagnosis, and input the repair information data of the parts into the data platform module;

[0070] 2) The data platform module formulates a preliminary maintenance plan based on historical maintenance data, knowledge base and instance database, simulates the preliminary maintenance plan in the virtual space, and calls the knowledge base in the data platform to carry out the preliminary maintenance plan Judgment, if it is not the optimal maintenance plan, continue to simulate in the virtual space, and correct the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com