Heat conduction induction coal-fired boiler flame detector

A technology for flame detectors and coal-fired boilers, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of easy damage of detection probes, unfavorable operators to monitor furnace combustion conditions, and affect detection results, etc., to achieve good protection performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

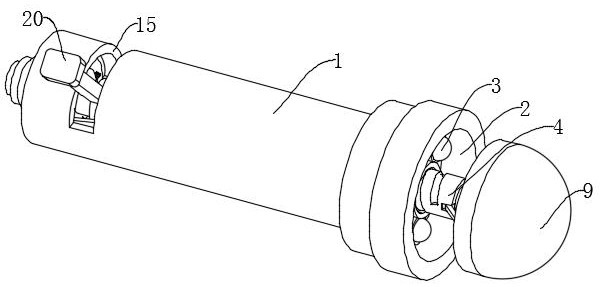

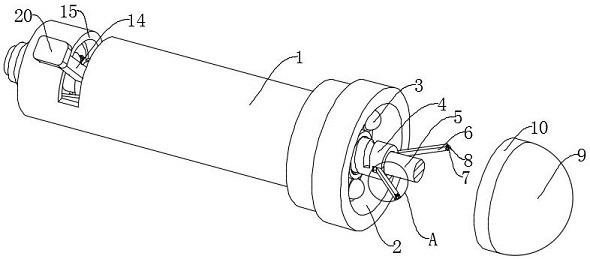

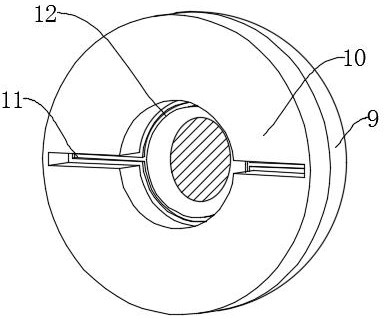

[0035] see Figure 1-7 , a coal-fired boiler flame detector with heat conduction induction, comprising a casing 1 and an induction probe 3, a groove 2 is provided at one end of the casing 1, the induction probe 3 is fixedly connected with the inner bottom surface wall of the groove 2, and the inner bottom surface of the groove 2 The wall is spirally connected with a threaded driving rod 4, and the inside of the threaded driving rod 4 is rotatably connected with a support rod 5. One end of the support rod 5 extends to the outside of the shell 1 and is fixedly connected with a protective cover 9. A chute is provided inside the protective cover 9. Inside the chute Embedded with a sliding post 8, one end of the threaded driving rod 4 is rotatably connected to the first connecting rod 6, the sliding post 8 is rotatably connected to the end of the first connecting rod 6 away from the threaded driving rod 4 through the rotating seat 7, and the inner side of the protective cover 9 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com