A fan blade assembly and its motor

A technology of fan blades and components, applied in the direction of electric components, pump components, mechanical equipment, etc., can solve problems such as damage to fan blades, difficulty in installation, fracture and failure of fan blades, etc., to increase dynamic unbalance, reduce the use of tools, and avoid The effect of increased difficulty in processing and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

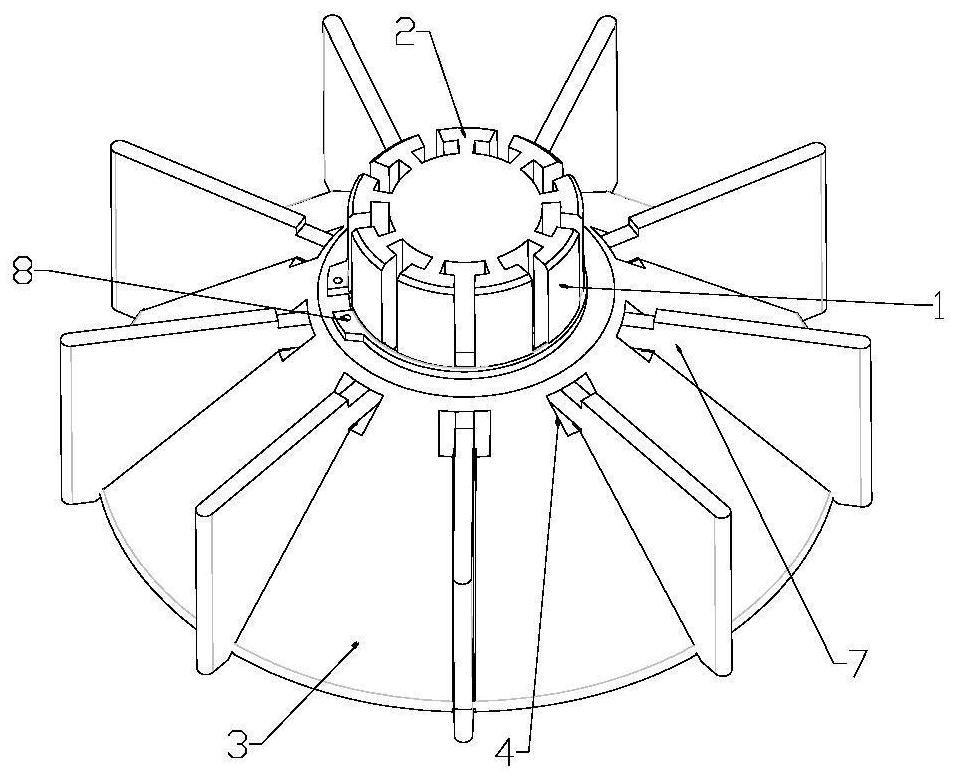

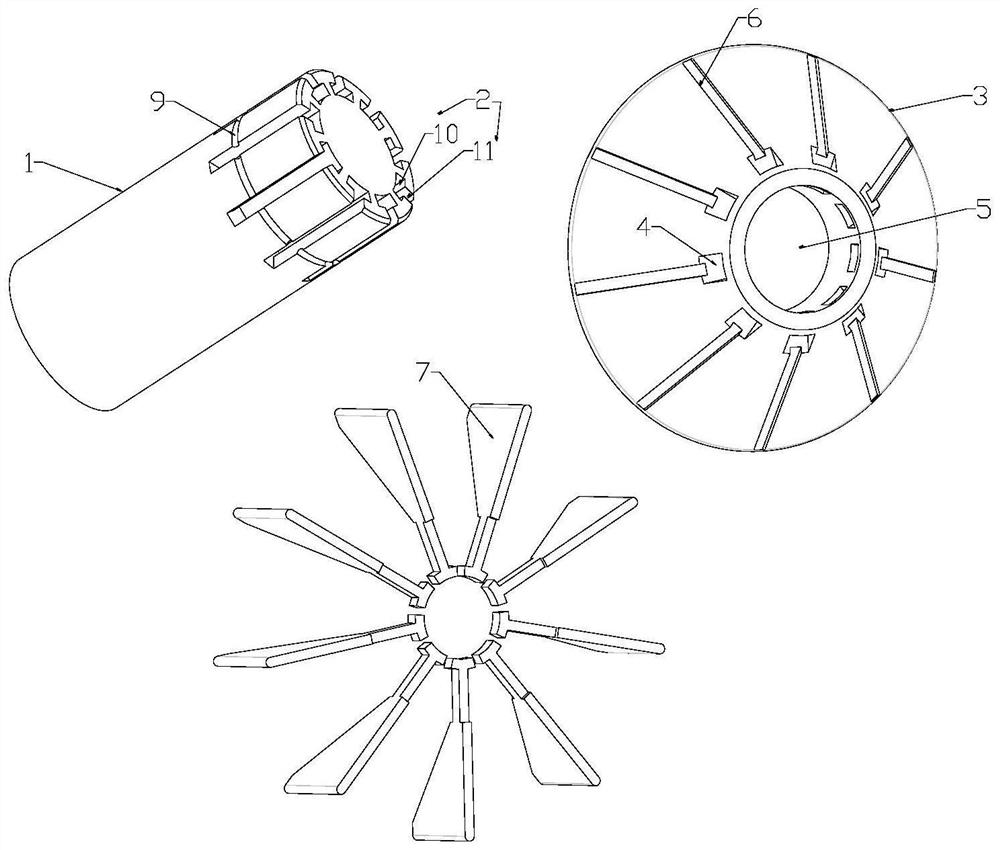

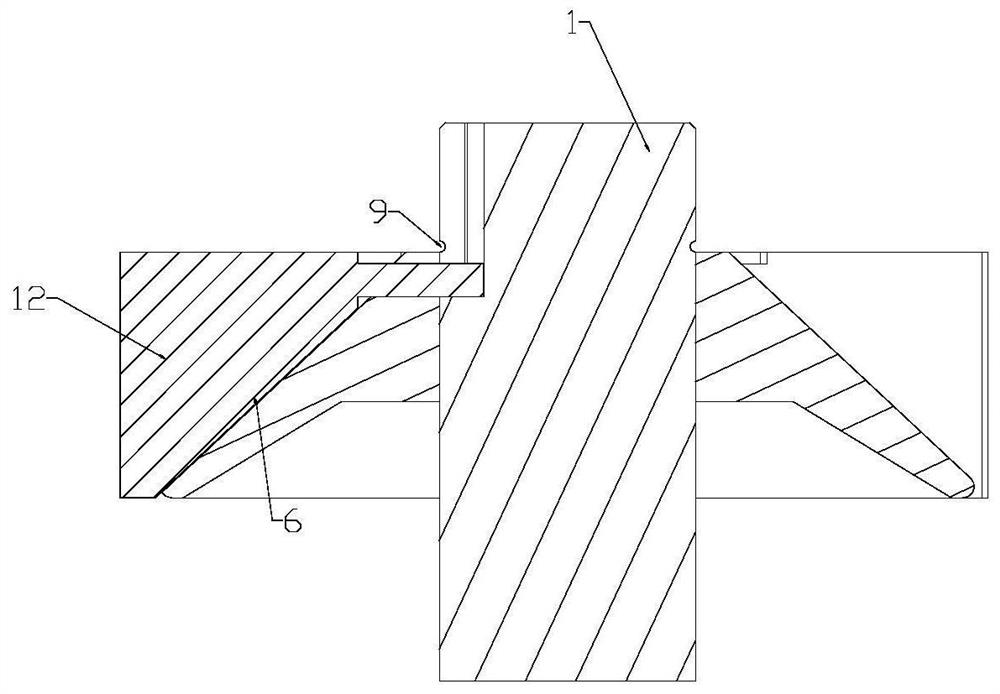

[0024] like Figure 1-2 The illustrated novel fan blade assembly includes: a shaft body 1, the top of the shaft body 1 is provided with an installation keyway 2, and the installation keyway 2 extends from the outside to the inside to the middle of the shaft body 1; The middle part of the air disc 3 is provided with a splicing through hole 5 that is tightly fitted with the shaft body 1; the side end of the air disc 3 is provided with a mounting hole 4, and the mounting hole 4 faces the splicing through hole 5; The blade 7, the fan blade 7 can pass through the installation hole 4 and the installation keyway 2 in sequence, and the wind disc 3 and the shaft body 1 can be detachably connected as a whole.

[0025] In this embodiment, the fan blades can pass through the installation holes in sequence, the installation keyway is detachably connected to the fan plate and the shaft body, which can realize convenient and fast installation and disassembly, and can reduce excessive use of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com