Transportation moistureproof frame for moist and agglomerated regenerated plastic particles in transportation

A technology for recycling plastic particles and moisture, which is used in the field of plastic product production and processing equipment to prevent moisture agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

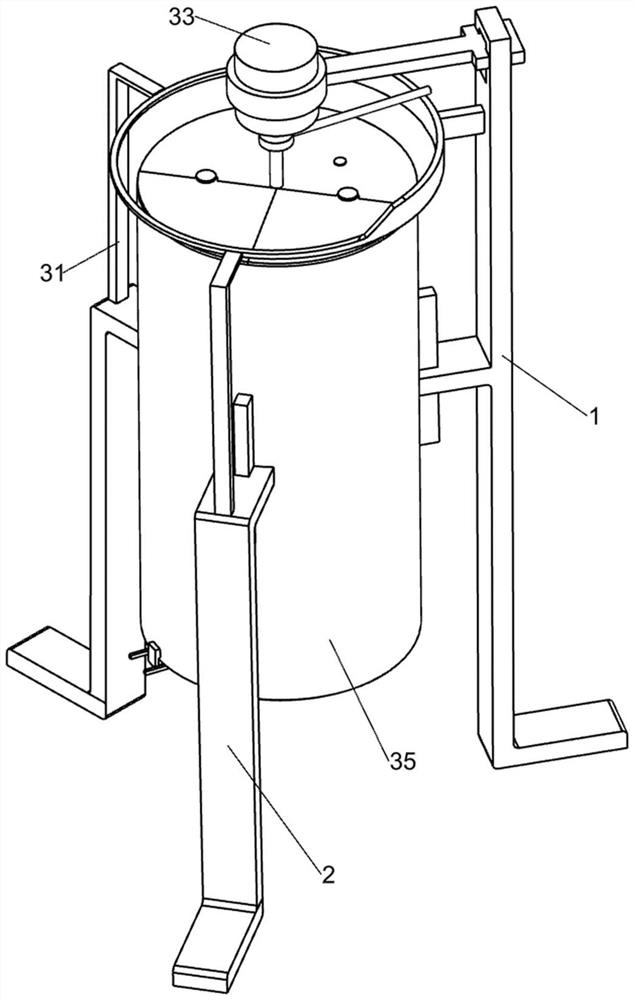

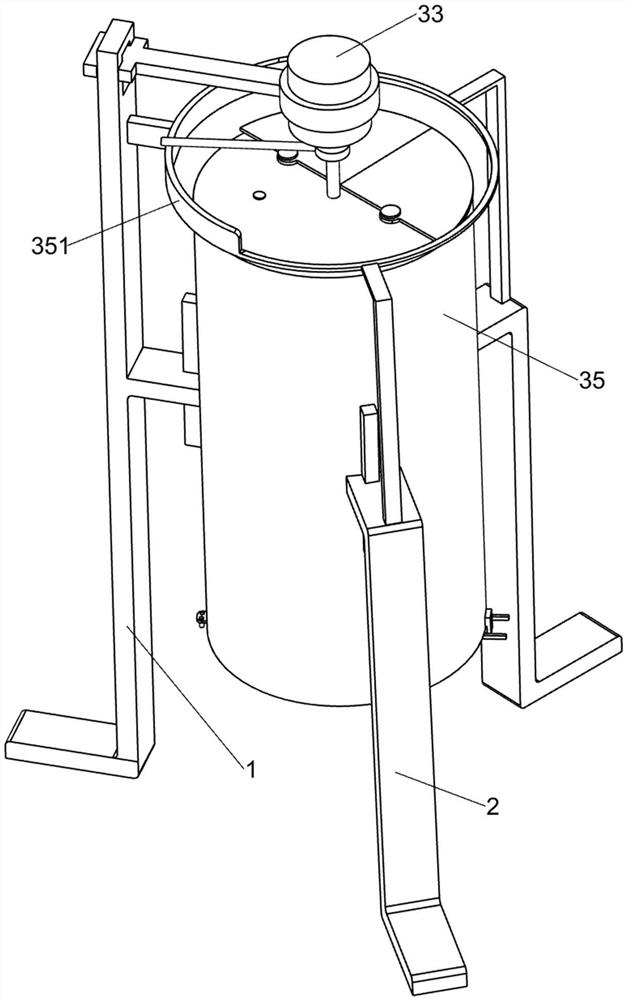

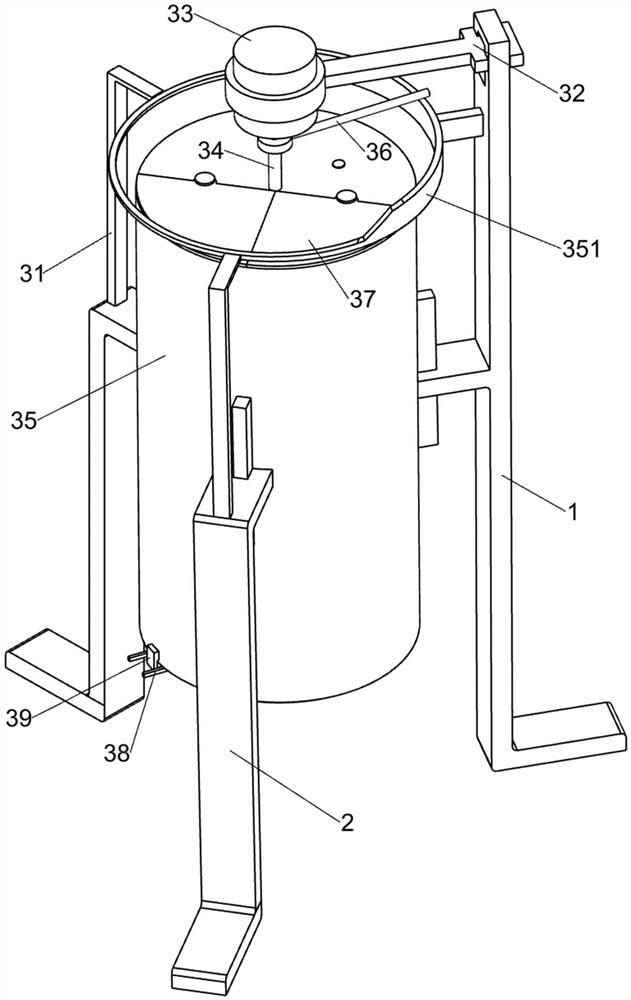

[0022]A transport moisture-proof box for moist cakes for regenerative plastic particles in transportation, such asFigure 1-6As shown, including the support frame 1, the support frame 2, the jitter assembly 3, the slope rotation assembly 4, the outer rotating assembly 5, the rotary raised assembly 6, and the support frame 1 and the two struts 2 are commonly sliding connection. The jitter assembly 3, the jitter assembly 3 is used to make the regenerated plastic particles on the top of the regenerated plastic particles, so that the reproduced plastic particles are not bonded together, and the slope rotation assembly 4 is fixed to the jitter assembly 3, and the outer rotating assembly 5 is set in the jitter assembly 3. The rotary raised assembly 6 is provided on the slope rotation assembly 4, and the rotary assembly 6 is used to stir the regenerative plastic particles, prevent regeneration plastic particles from being subjected to moisture, and slope rotation assembly 4, external rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com