Liquid pump

A liquid pump and pump body technology, applied in the field of liquid pumps, can solve the problems of unfavorable environmental protection recycling of POM materials, failure of overall recycling of pump core products, easy cracking of the lower part of the piston, etc., to achieve simple structure, good anti-loosening effect, and stable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

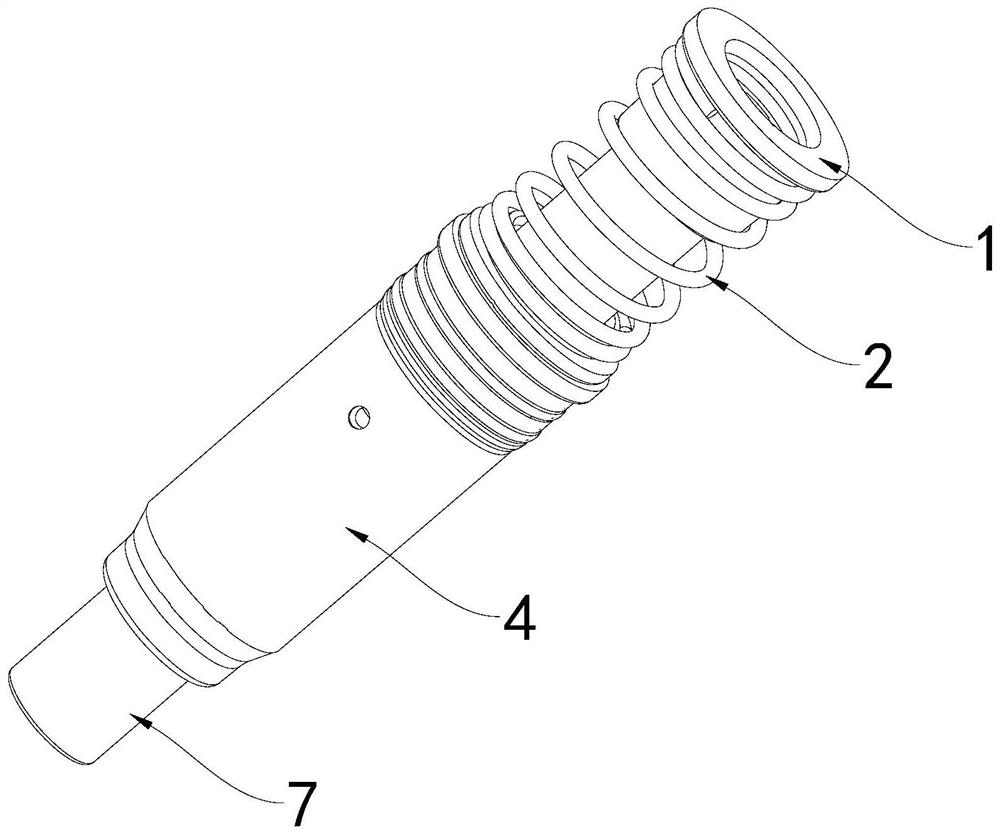

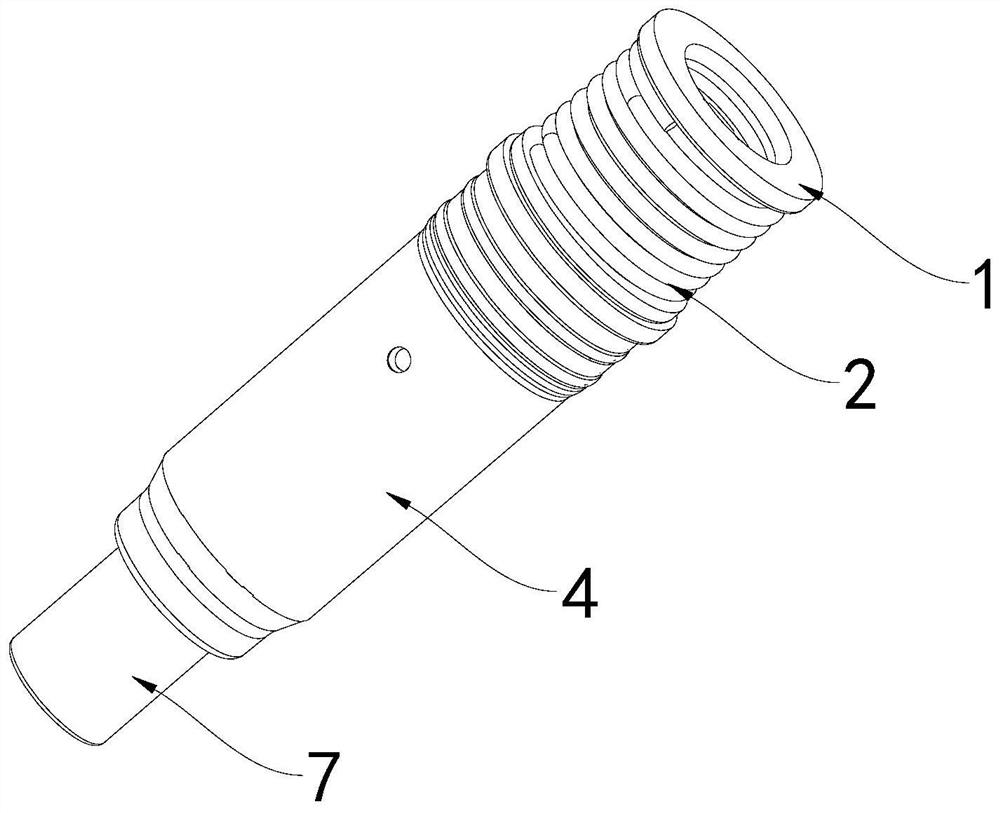

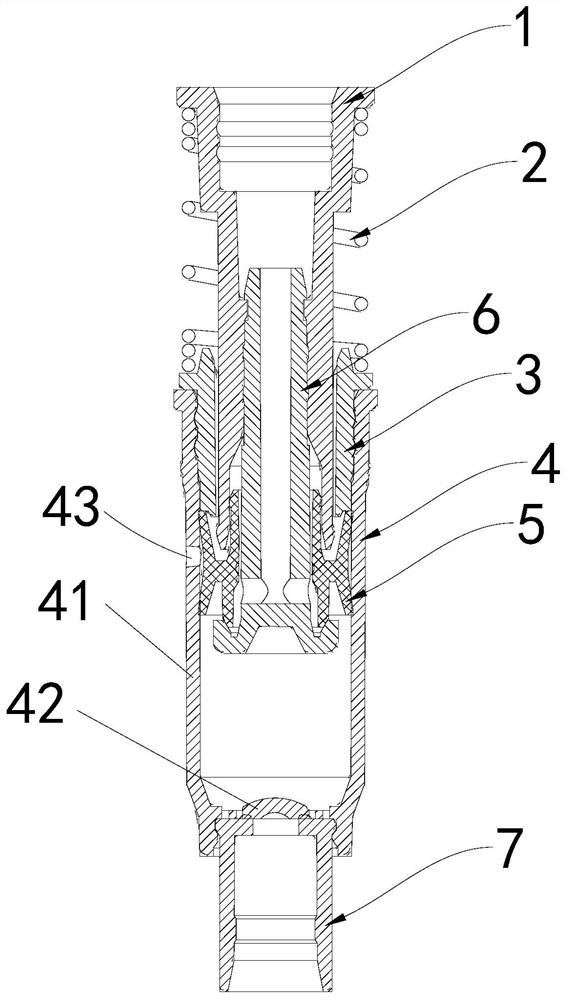

[0056] see Figure 1 to Figure 4 The shown liquid pump includes a connecting rod 1, a spring 2, a lock cover 3, a pump body 4, a piston 5, a piston rod 6, and a valve seat 7, wherein the valve seat 7 is installed on the pump body 4 At the lower end, the lock cover 3 is fixed on the upper end of the pump body 4, the connecting rod 1 and the lock cover 3 are slidingly fitted, the piston rod 6 is fixedly connected with the connecting rod 1, and the piston 5 is slidably sleeved on the piston rod 6, And the piston 5 is slidably arranged in the pump body 4 and sealedly connected with the pump body 4 . see Figure 5 , Figure 6 As shown, the upper end of the connecting rod 1 is fixedly provided with a pressing head cap 8, the pump body 4 is installed in the pump cover 9 of containers such as bottles, and the bottom of the valve seat 7 is fixedly provided with a suction pipe 10 to extend into the container to absorb liquid.

[0057] The detailed structure of the liquid pump is desc...

Embodiment 2

[0083] see Figure 20 to Figure 27 As shown, the main difference between the liquid pump shown in this embodiment and the liquid pump in Embodiment 1 is that the liquid pump in this embodiment is a vacuum pump, and the shell 41 of the pump body 4 does not need to be provided with balancing air holes.

[0084] In summary, the liquid pump of the present invention has a small number of overall parts, which saves production costs, makes product assembly more convenient, and has strong product durability. At the same time, each part of the liquid pump is basically made of recyclable plastics, which can fully recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com