Workpiece clamp convenient to clamp special-shaped surface for machining

A technology of mechanical processing and special-shaped surfaces, which is applied in the direction of workpiece clamping devices, manufacturing tools, mechanical equipment, etc., and can solve problems such as uneven workpiece shapes, damaged workpieces, and difficult fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

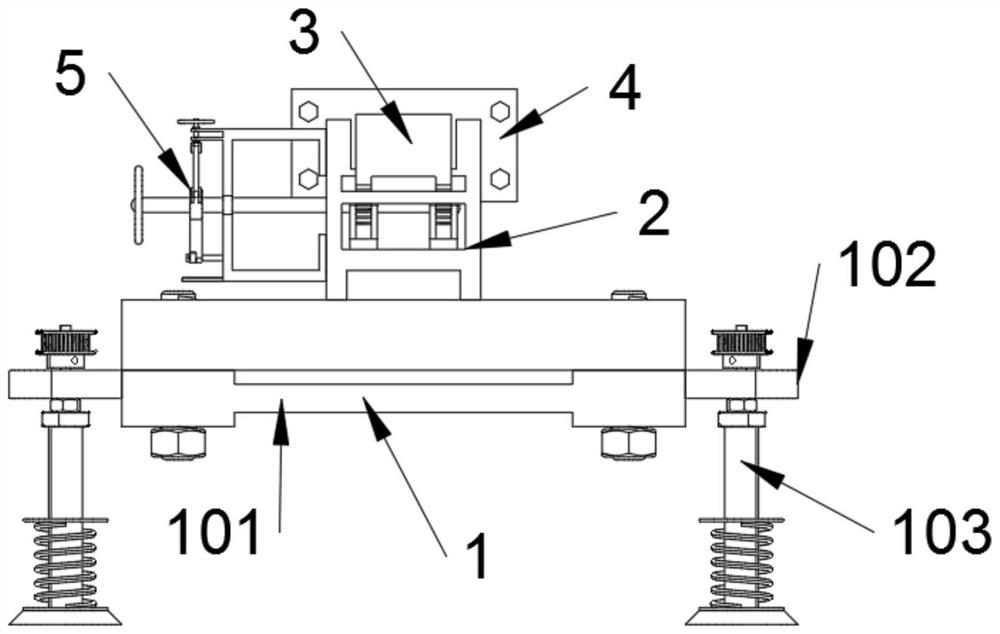

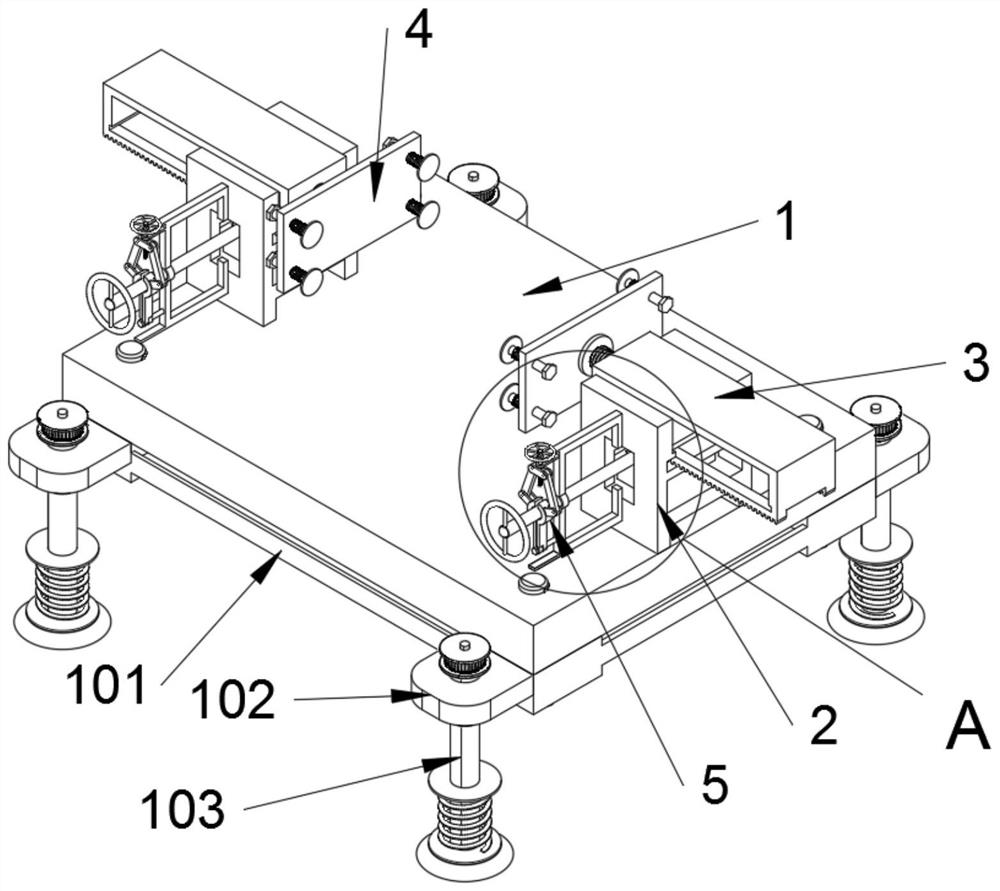

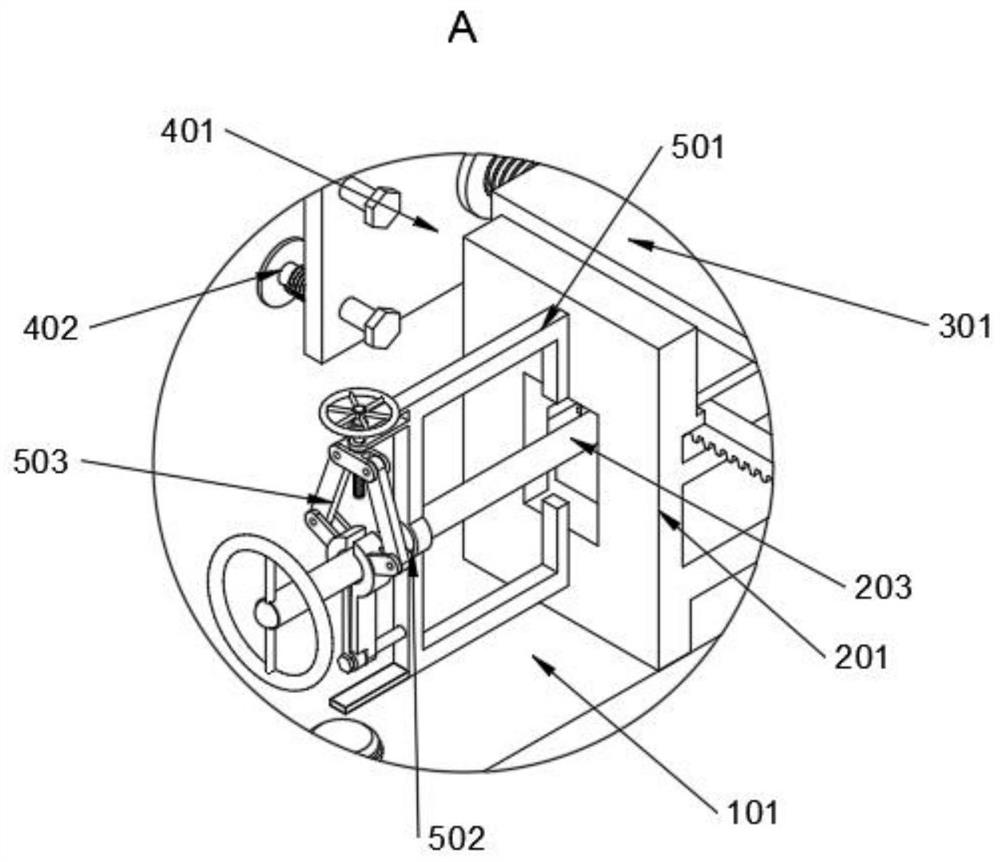

[0030] as attached figure 1 To attach Figure 6 Shown:

[0031] The present invention provides a workpiece clamp for mechanical processing that is convenient for clamping special-shaped surfaces, including: a support mechanism 1, an adjustment mechanism 3, a clamping mechanism 4 and a limit mechanism 5, and the front and rear ends of the support mechanism 1 are symmetrically provided with a The bracket mechanism 2; the adjustment mechanism 3 is slidably connected to the upper position inside the bracket mechanism 2; the middle position of the front end of the clamping mechanism 4 is slidably connected to the middle position of the rear end of the adjustment mechanism 3; the clamping mechanism 4 includes a splint 401, a spring pad 402 and a clip Sheet 403, spring pad 402 is positioned on clamping plate 401 slide bar, clamping piece 403 front end surface is provided with slide bar, and is provided with spring, clamping piece 403 slide bar is slidably connected in the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com