Bifida ferment plant pre-essence

A technology of bifid yeast and muscle base liquid, which is applied in the direction of cosmetics, cosmetic preparations, dressing preparations, etc., can solve the problems of large irritation and skin side effects, and achieve the effect of less irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

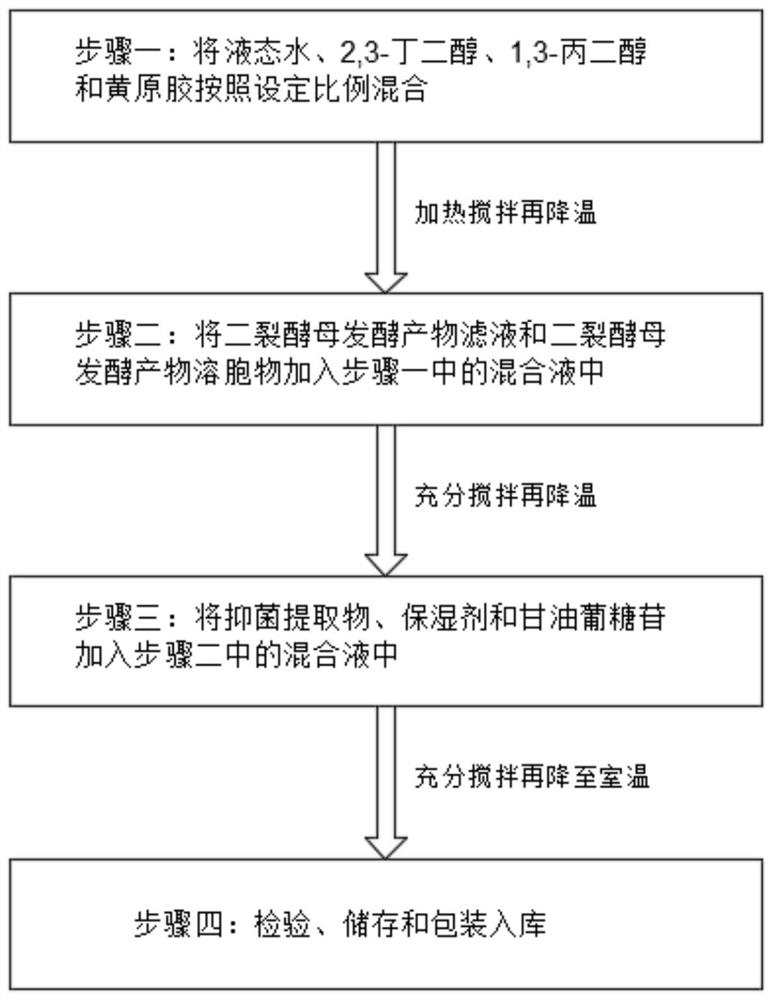

[0023] refer to figure 1 , Bifid yeast plant muscle bottom fluid, take liquid water: 292g, Bifid yeast fermentation product filtrate: 40g, Bifida yeast fermentation product lysate: 20g, 2,3-butanediol: 5g, 1,3-propanediol : 3g, antibacterial extract: 1g, 4D hyaluronic acid: 1g, glycerol glucoside: 0.5g, xanthan gum: 0.3g;

[0024] The antibacterial extract uses one or any combination of cinnamon extract, star anise fruit extract, capillary wormwood extract and yeast fermentation product extract, 4D hyaluronic acid uses sodium hyaluronate cross-linked polymer, hyaluronic acid One or any combination of sodium hyaluronate, acetylated sodium hyaluronate and hydrolyzed sodium hyaluronate.

[0025] The above raw materials are processed according to the following steps:

[0026] Step 1: Mix liquid water, 2,3-butanediol, 1,3-propanediol and xanthan gum into the container, heat to 75 degrees Celsius, keep stirring for 4 hours, and then cool to 43 degrees Celsius;

[0027] Step 2: Ad...

Embodiment 2

[0031] refer to figure 1 , Bifid yeast plant muscle bottom fluid, take liquid water: 292g, Bifid yeast fermentation product filtrate: 40g, Bifida yeast fermentation product lysate: 20g, 2,3-butanediol: 5g, 1,3-propanediol : 3g, antibacterial extract: 1g, 4D hyaluronic acid: 1g, glycerol glucoside: 0.5g, xanthan gum: 0.3g;

[0032] The antibacterial extract uses one or any combination of cinnamon extract, star anise fruit extract, capillary wormwood extract and yeast fermentation product extract, 4D hyaluronic acid uses sodium hyaluronate cross-linked polymer, hyaluronic acid One or any combination of sodium hyaluronate, acetylated sodium hyaluronate and hydrolyzed sodium hyaluronate.

[0033] The above raw materials are processed according to the following steps:

[0034] Step 1: Mix liquid water, 2,3-butanediol, 1,3-propanediol and xanthan gum into the container, heat to 80 degrees Celsius, keep stirring for 4 hours, and then cool to 45 degrees Celsius;

[0035] Step 2: ad...

Embodiment 3

[0039] refer to figure 1 , Bifid yeast plant muscle bottom fluid, take liquid water: 292g, Bifid yeast fermentation product filtrate: 40g, Bifida yeast fermentation product lysate: 20g, 2,3-butanediol: 5g, 1,3-propanediol : 3g, antibacterial extract: 1g, 4D hyaluronic acid: 1g, glycerol glucoside: 0.5g, xanthan gum: 0.3g;

[0040] The antibacterial extract uses one or any combination of cinnamon extract, star anise fruit extract, capillary wormwood extract and yeast fermentation product extract, 4D hyaluronic acid uses sodium hyaluronate cross-linked polymer, hyaluronic acid One or any combination of sodium hyaluronate, acetylated sodium hyaluronate and hydrolyzed sodium hyaluronate.

[0041] The above raw materials are processed according to the following steps:

[0042] Step 1: Mix liquid water, 2,3-butanediol, 1,3-propanediol and xanthan gum into the container, heat to 85 degrees Celsius, keep stirring for 4 hours, and then cool to 47 degrees Celsius;

[0043] Step 2: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com