A preparation method of deep hole interconnection structure based on nanometer metal

A technology of nano-metal and interconnection structure, applied in the direction of nano-technology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of environmental pollution and environmental pollution, and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

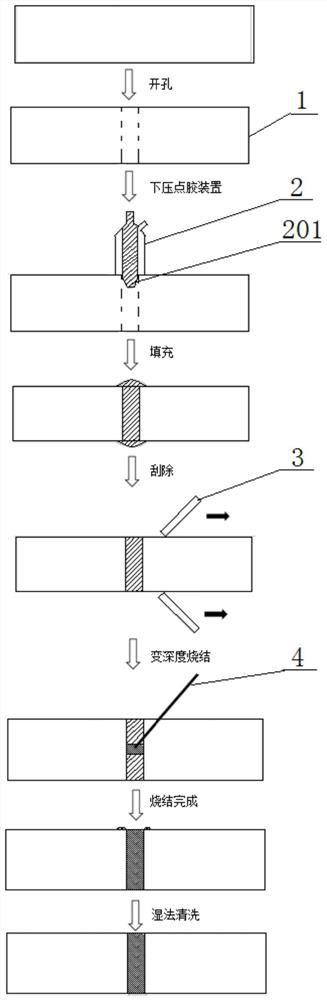

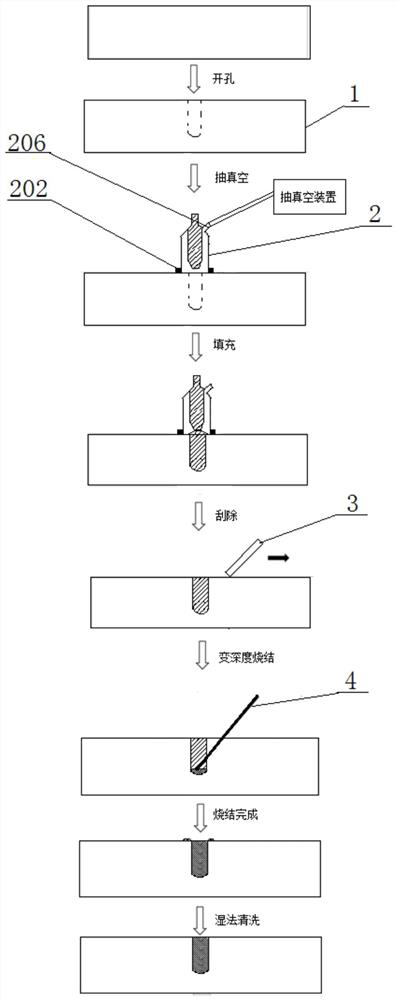

[0047] Such as figure 1 As shown, a method for preparing a deep-hole interconnection structure based on nanometer metal, for an interconnection structure in which the deep hole is a through hole, comprises the following steps:

[0048] S1. Using laser processing or physical cutting or chemical etching to form through holes on the glass plate 1 to be formed with a deep hole interconnection structure;

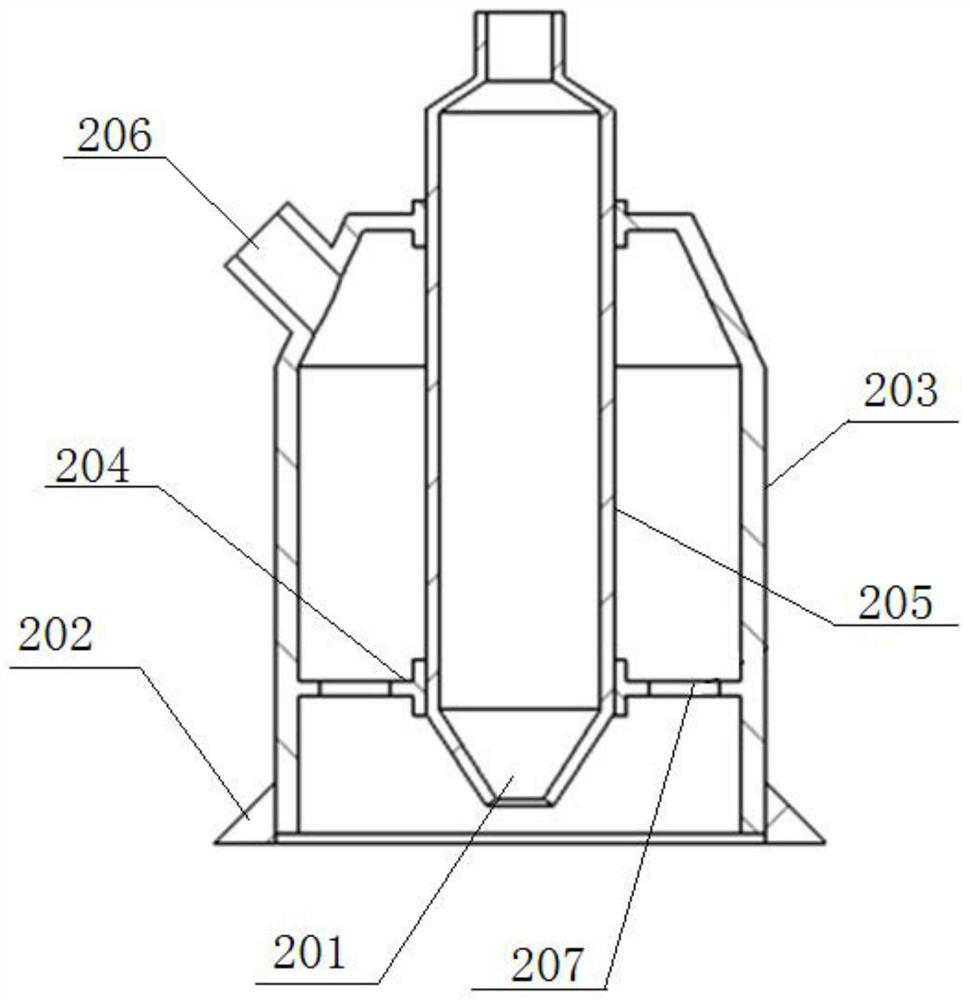

[0049] S2. Move the dispensing device 2 to the through hole facing the glass plate 1, press down the dispensing device 2, and the dispensing head 201 of the dispensing device 2 extends into the through hole to seal the through hole, and then the nano-metal The paste is squeezed into the through hole, and then the automatic optical inspection system is used to judge whether the nano metal paste is completely filled in the through hole. When the through hole is not completely filled, continue to squeeze the nano metal paste into the through hole. When the through hole is completely...

Embodiment 2

[0074] refer to figure 1 For example, a method for preparing a deep hole interconnection structure is provided. For an interconnection structure in which the deep hole is a through hole, the following steps are included:

[0075] S1, using CO with a wavelength of 10.6 μm, a pulse width of 500 ps, a frequency of 5 Hz, and a power of 5 mJ 2 Laser, processing a through hole with a diameter of 1.2 μm on the glass plate 1, the through hole is perpendicular to the surface of the glass plate 1, penetrates the upper and lower surfaces, the cross section of the through hole is circular, and the depth is 70 μm;

[0076] S2. Move the dispensing device 2 to the through hole facing the glass plate 1, press down the dispensing device 2, and the dispensing head 201 of the dispensing device 2 extends into the through hole until one end of the through hole is sealed and squeezed The nano-copper paste in the dispensing head 201 makes the nano-copper paste fill in the through hole. The shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com