Packaging control method and system and medium

A control method and control system technology, applied in the field of server production management, can solve the problems of time-consuming and labor-intensive recording of ex-factory information, less or wrong delivery, and more packaging and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

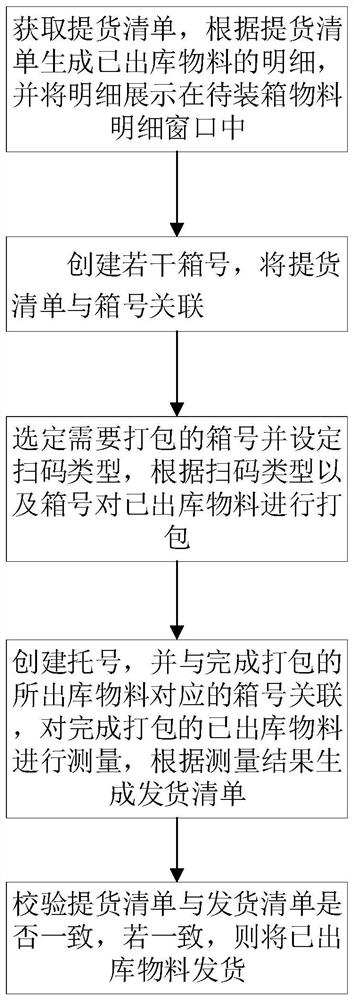

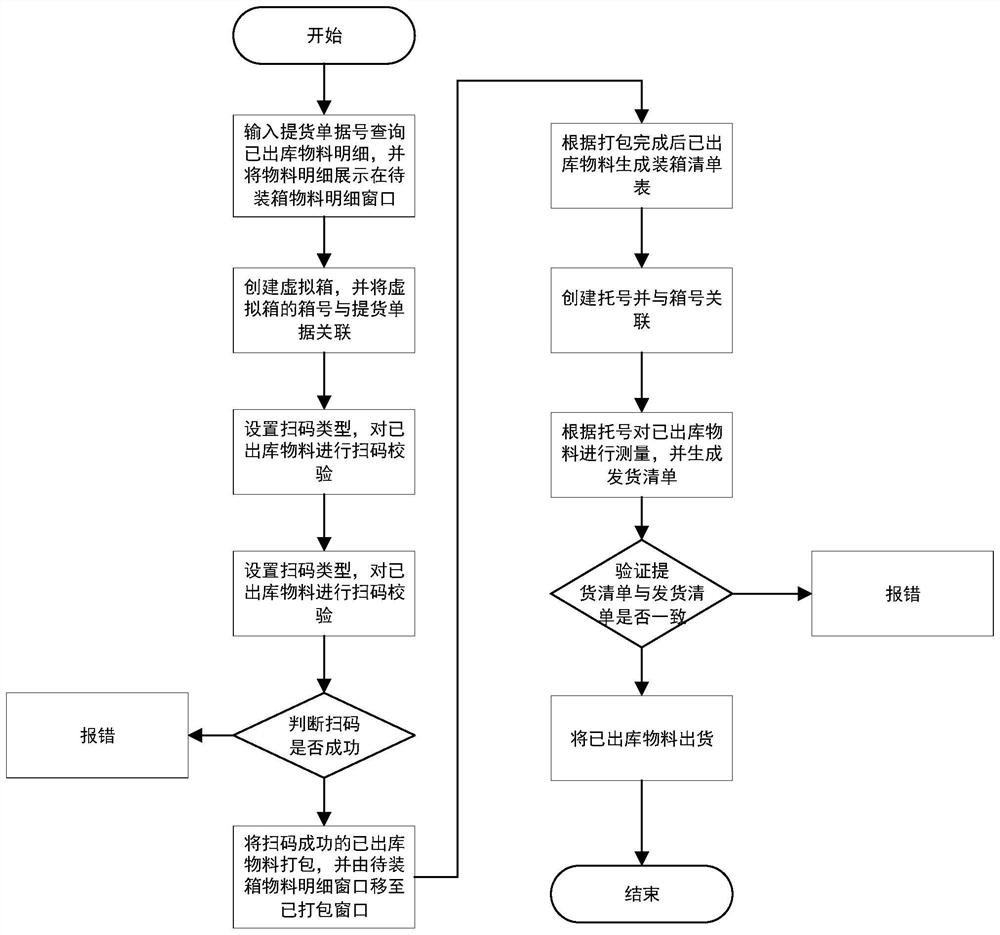

[0039] The embodiment of the present invention provides a packaging control method, please refer to figure 1 and figure 2 , including the following steps;

[0040] S100. Input the delivery document number, query the details of the materials that have been delivered from the warehouse through the delivery document number, and display the material details in the material details window to be packed;

[0041] S200, create a virtual box, and create a box number for the virtual box, each virtual box corresponds to a box number, and associate the box number with the document queried in step S100;

[0042] S300. After the box number is created, select the box number and select the code scanning type for the virtual box corresponding to the box number. In the material details window to be packed, select the material to be packaged, and scan the material to be packaged through the code scanning device. The scanning code types are: PN is the original factory part number, SN is the su...

Embodiment 2

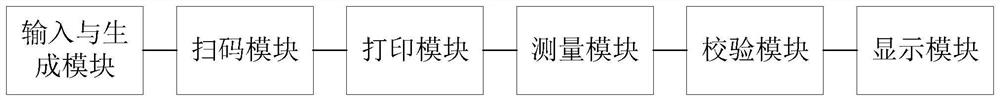

[0060] The embodiment of the present invention provides a packaging control system, please refer to image 3 , including: input and generation module, code scanning module, printing module, measurement module, verification module, modification module and display module.

[0061] The input and generation module is used to receive the delivery document number. When the input and generation module receives the delivery document number, it will query the details of the materials that have been shipped out of the document according to the delivery document number. The input and generation module is equipped with details of materials to be packed Window, you can display the materials that have been delivered from the warehouse in the material details window to be packed. Through the box number generation function of the input and generation module, each material has a unique barcode to generate a new box number, and the newly generated The box number is associated with the delivery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com