Method, device and system for detecting leakage of storage tank

A technology of storage tank and position information, applied in measuring devices, by detecting the appearance of fluid at the leak point, testing the fluid tightness, etc., it can solve the problem of lack of detection capability of the center of the tank bottom, difficult to meet explosion-proof requirements, and detection signals. Large attenuation and other problems, to achieve the effect of reducing hidden dangers in detection, avoiding excessive maintenance and economic waste, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

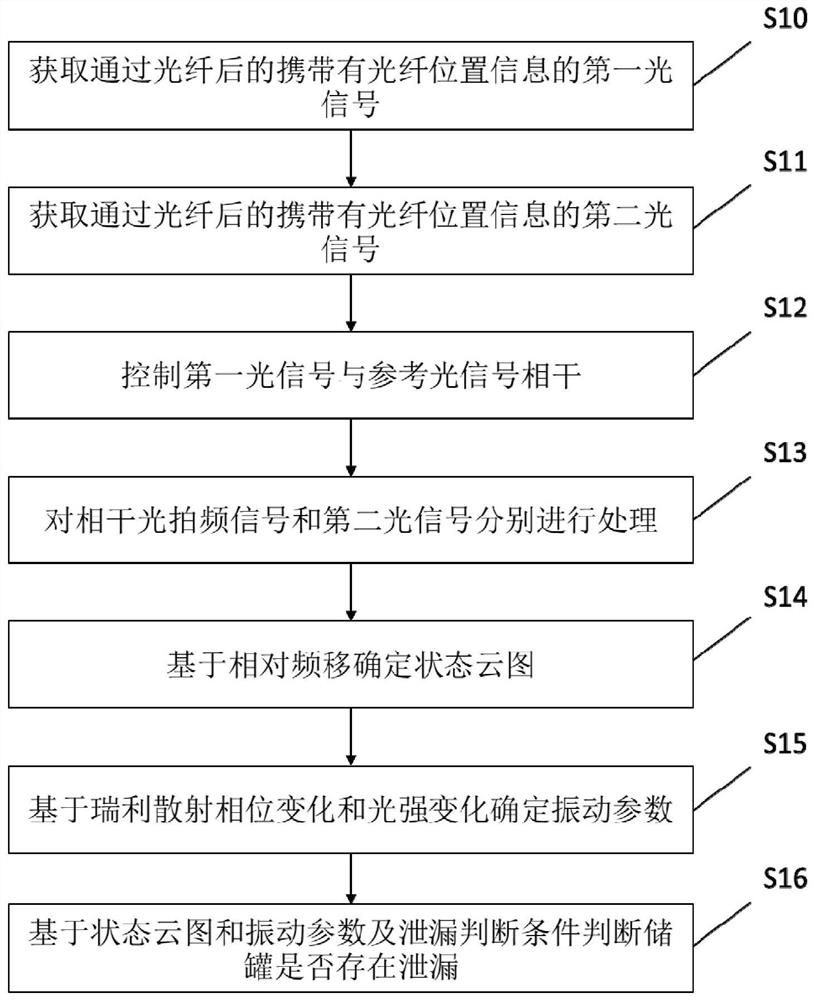

[0034] figure 1It is a flow chart of the method for detecting the leakage of the storage tank provided by Embodiment 1 of the present invention. Wherein, the surface of the storage tank is arranged with optical fibers and the optical fibers are sensitive to temperature but insensitive to strain. Wherein, the manner of arranging the optical fiber on the surface of the storage tank may depend on specific conditions. For example, for a new storage tank, the optical fiber can be arranged on the surface of the storage tank in the following way: on the lower surface of the storage tank floor, starting from the center of the tank bottom, laying concentric rings to the edge of the tank bottom, and winding from the inlet and outlet After 2 turns, it is connected to the outer wall of the bottom plate of the storage tank, and the optical fiber is laid on the outer wall of the storage tank in a circular parallel winding manner at a distance of 1m to the highest liquid level of the storag...

Embodiment 2

[0048] figure 2 It is a structural block diagram of the device for detecting storage tank leakage provided by Embodiment 2 of the present invention. like figure 2 As shown, the device includes a first acquisition module 1 , a second acquisition module 6 , a coherence module 2 , a signal processing module 3 , a state nephogram determination module 4 , a vibration parameter determination module 7 and a leakage determination module 5 . Wherein, the first acquisition module 1 is used to acquire the first optical signal carrying the position information of the optical fiber after passing through the optical fiber, wherein the first optical signal includes backward Stokes light generated based on the Brillouin scattering effect; The second acquisition module 6 is used to acquire the second optical signal carrying the position information of the optical fiber after passing through the optical fiber, wherein the second optical signal includes Rayleigh scattered light generated base...

Embodiment 3

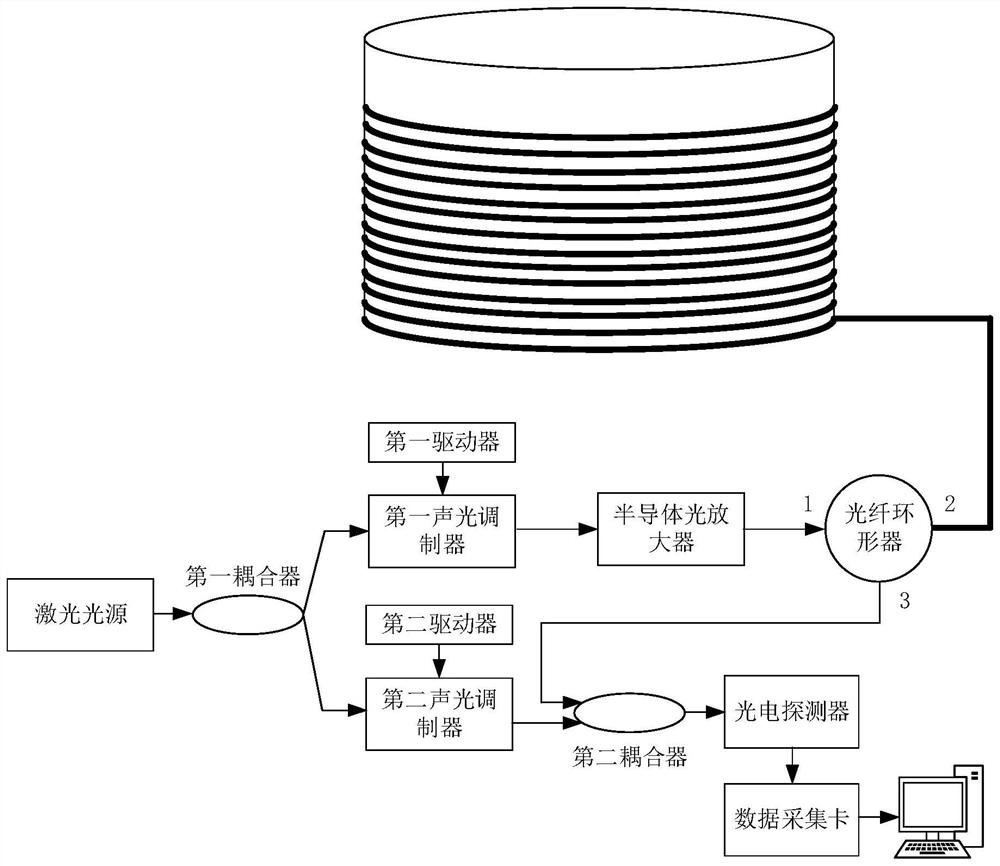

[0058] Combine below image 3 and Figure 4 The system for detecting leakage of a storage tank provided in the embodiment of the present invention is explained, wherein the content explained can also be used to explain the method and device for detecting leakage of a storage tank in the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com