Valve apparatus for vehicle

A technology for equipment and vehicles, applied in mechanical equipment, multi-port valves, valve devices, etc., can solve the problems of rapid temperature rise of transmission fluid, deterioration of engine room space utilization, difficult positioning of components, etc., so as to improve overall fuel efficiency, friction and friction. The effect of reduced losses, simplified production and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

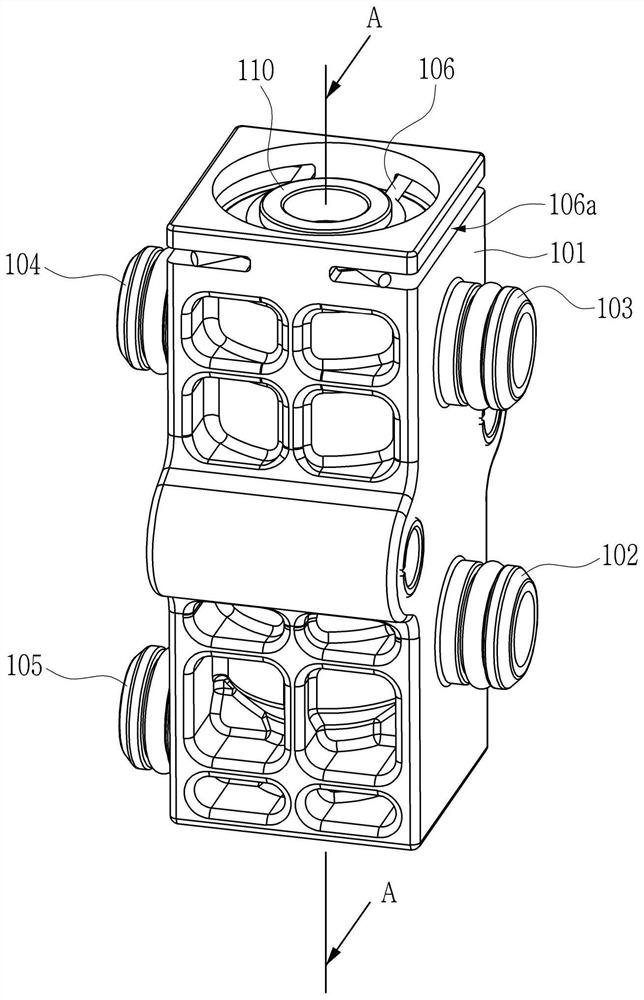

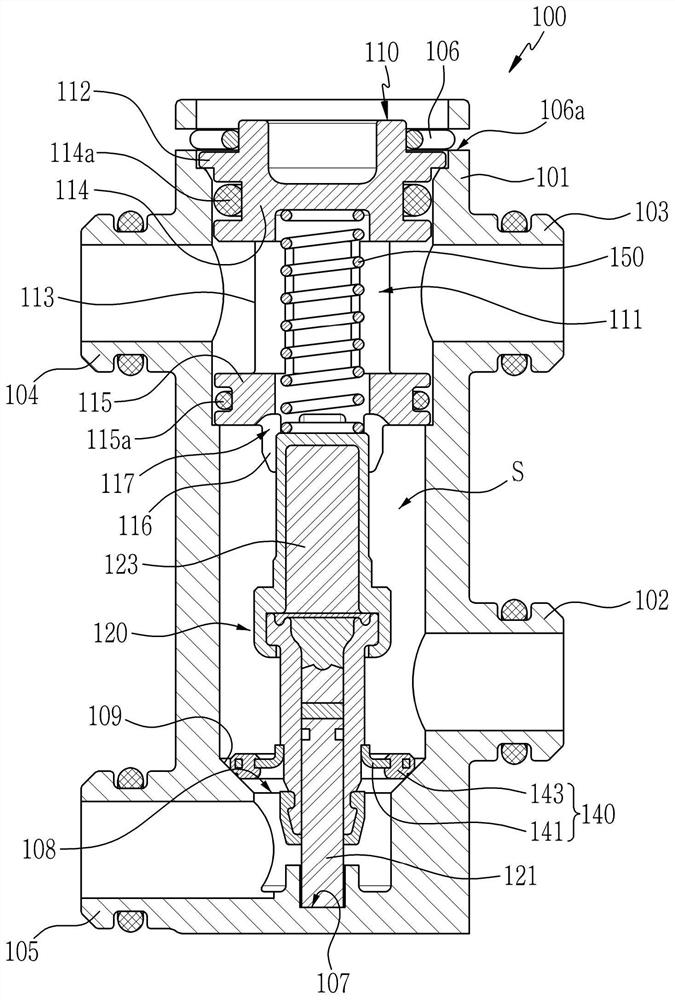

[0043] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0044] The exemplary embodiments disclosed in this specification and the configurations depicted in the drawings are only preferred embodiments of the present invention, and do not cover the entire scope of the present invention. Therefore, it will be understood that various equivalents and modifications may exist in applying the present description.

[0045] To clarify the present invention, parts irrelevant to the description will be omitted, and the same elements or equivalents will be denoted by the same reference numerals throughout the specification.

[0046] Also, the size and thickness of each element are arbitrarily shown in the drawings, but the present invention is not necessarily limited thereto, and in the drawings, the thicknesses of layers, films, panels, regions, etc. are exaggerated for clarity.

[0047] Furthermore, unle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com