A continuous heat treatment device for metal laminated composite plates

A technology of heat treatment device and composite plate, which is applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problems that the online continuous heat treatment of the metal composite plate cannot be realized, and the differential heat treatment of different coating metals cannot be realized. On-line continuous heat treatment and various heating methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

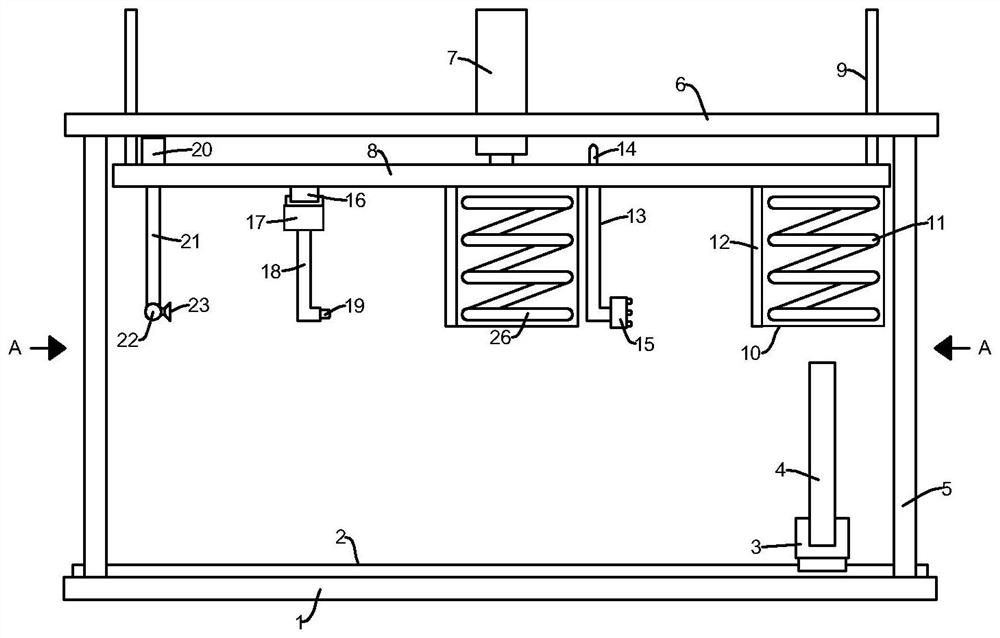

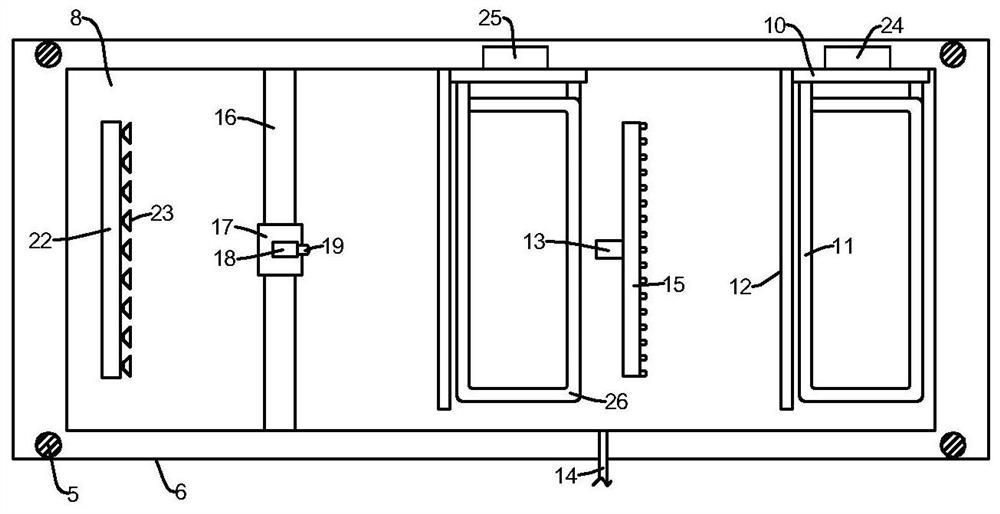

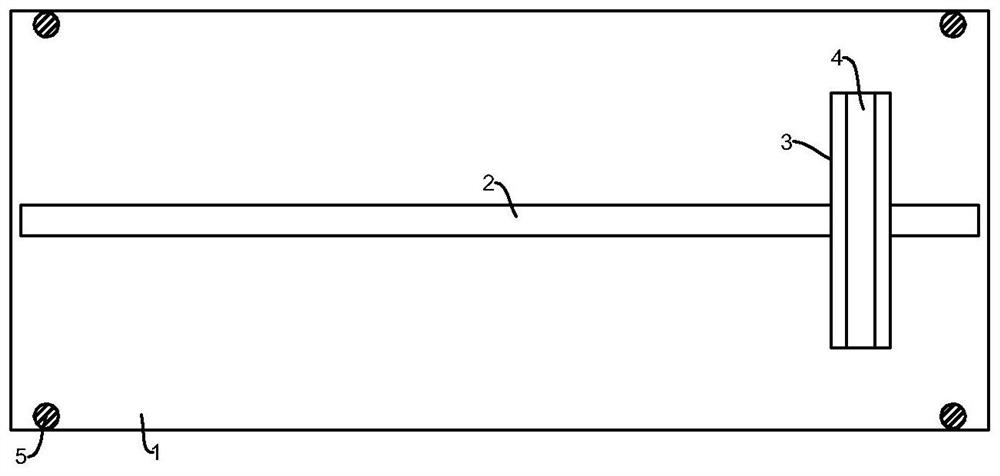

[0018] refer to Figure 1-3 , a continuous heat treatment device for metal layered composite plates, including a bottom plate 1, a first linear motor 2 is fixed on the upper surface of the bottom plate 1, and an inverted “ 匚"-shaped clamping plate 3, the metal layered composite plate 4 is inserted in the clamping plate 3, the two ends of the edge of the bottom plate 1 on both sides of the first linear motor 2 are vertically fixed with fixed columns 5, four The top plate 6 is vertically fixed on the end of the fixed column 5 away from the bottom plate 1, and the center of the top plate 6 runs through and is fixedly provided with a cylinder 7, and a mobile plate 8 is vertically fixed on the top of the push rod of the cylinder 7, and the mobile plate 8 It is arranged between the bottom plate 1 and the top plate 6, and the moving plate 8 is respectively fixed with a high-frequency induction heating mechanism, a surface flame heating mechanism, an electromagnetic induction heating m...

Embodiment 2

[0021] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that both the high-frequency induction heating mechanism and the electromagnetic induction heating mechanism include a fixed plate 10, and the fixed plate 10 is vertically fixed on the opposite side of the moving plate 8 and the bottom plate 1. On the side, one end of the fixed plate 10 is vertically fixed with a shielding plate 12, and the two fixed plates 10 are respectively fixed with an induction coil 11 and an electromagnetic coil 26 corresponding to the metal layered composite plate 4, and the shielding plate 12 can sense The coil 11 and the electromagnetic coil 26 play the role of shielding, and then play the role of protection for the induction coil 11 and the electromagnetic coil 26, and the induction coil 11 and the electromagnetic coil 26 are respectively connected with a first heating power supply 24 and a second heating power supply by wires ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com