Large-force-reduction-ratio low-impact releasing mechanism for linear low-impact separation device

A separation device and release mechanism technology, which is applied in the docking device of aerospace vehicles, etc., can solve the problems of limited belt separation structure, untestable test cost, obvious additional pollution, etc., to achieve reliable connection and separation, low power consumption, The effect of improving product reliability

Active Publication Date: 2021-05-11

BEIJING SATELLITE MFG FACTORY

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, traditional pyrotechnic products also have shortcomings such as large impact, obvious additional pollution, non-repeatability, non-test

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

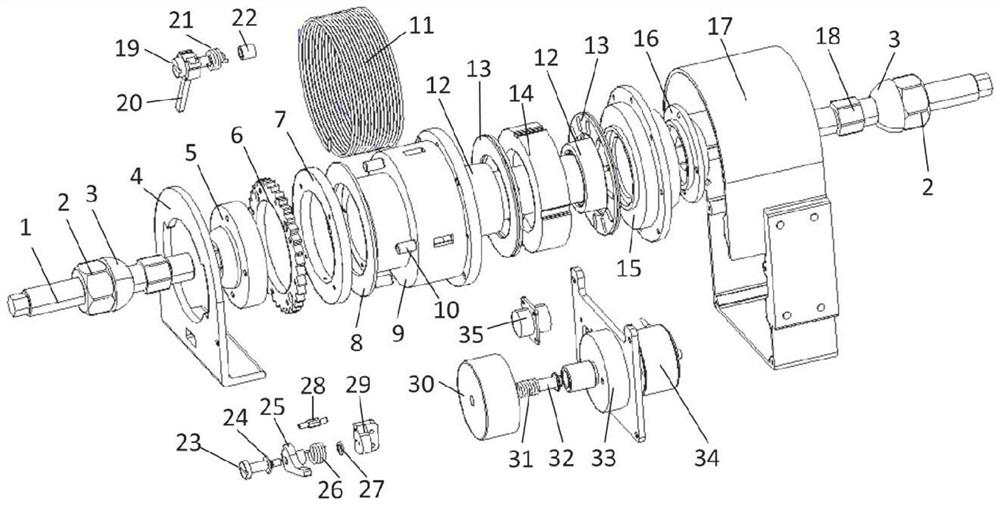

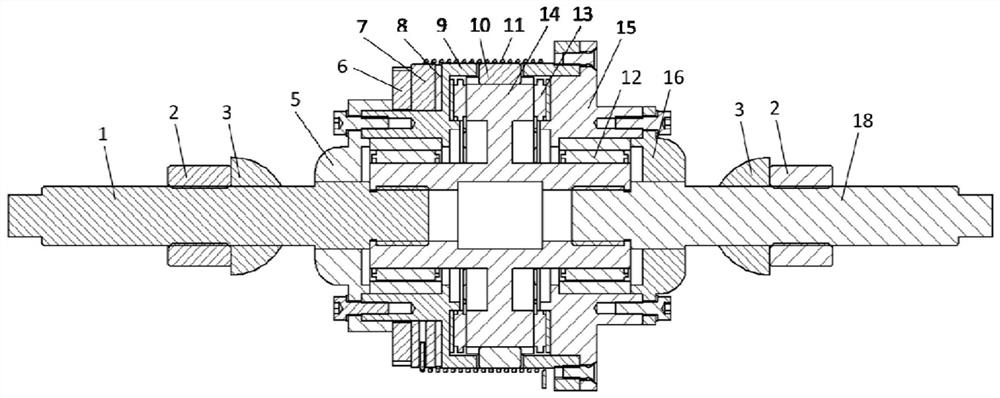

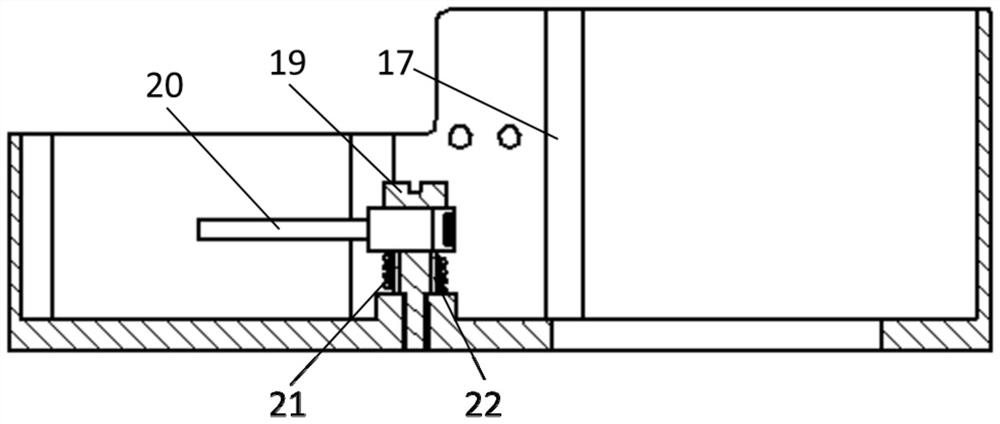

The invention discloses a large-force-reduction-ratio low-impact releasing mechanism for a linear low-impact separation device. The large-force-reduction-ratio low-impact releasing mechanism comprises a base 17, an upper cover 4, a connecting and separating assembly, a locking and unlocking assembly, an electromagnetic driving assembly and a pawl assembly. The mechanism has three working states, namely a connecting and locking state, an unlocking and separating state and a resetting state; (1) in the connecting and locking state, the connecting and separating assembly reduces the elastic pre-tightening force and then transmits the elastic pre-tightening force to the locking and unlocking assembly, and the locking and unlocking assembly further reduces the reduced elastic pre-tightening force and then transmits the reduced elastic pre-tightening force to the electromagnetic driving assembly; and the further reduced elastic pre-tightening force is maintained by the electromagnetic driving assembly, so that a bag belt is locked; (2) in the unlocking and separating state, the locking and unlocking assembly rotates to release lock of the connecting and separating assembly, so that the elastic pre-tightening force of the bag belt is released; and (3) after unlocking and separation are completed, the mechanism is restored to the connecting and locking state.

Description

technical field [0001] The invention relates to a low-impact release mechanism with a large force reduction ratio for a line-type low-impact separation device, which belongs to the technical field of low-impact line-type separation devices for rockets, satellites or spacecraft. Background technique [0002] At present, the spacecraft star-rocket separation system is mainly unlocked and released by the explosion of pyrotechnics. Typical star-rocket separation structures include belt-type separation structures and point-type separation structures. Most of the explosion energy of the point separation structure is transmitted to the spacecraft structures on both sides, and the high-frequency and high-amplitude stress waves may cause fatal damage to the spacecraft payload. However, in the separation process of the tape separation structure, because the tape falls off, the energy dissipation is relatively large, and the remaining energy is small, so the impact on the spacecraft is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B64G1/64

CPCB64G1/64

Inventor 李咚咚王波丁锋刘立成田昀徐杰李媛媛叶耀坤李委托孙国鹏

Owner BEIJING SATELLITE MFG FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com