Automatic operation control method of ship sewage storage device

A storage device and control method technology, applied in water treatment devices, separation methods, water/sewage treatment, etc., can solve the problems of equipment performance not meeting market demand, insufficient operating efficiency, safety, and equipment automation, etc. Achieve the effect of increasing the effective storage capacity, preventing clogging and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

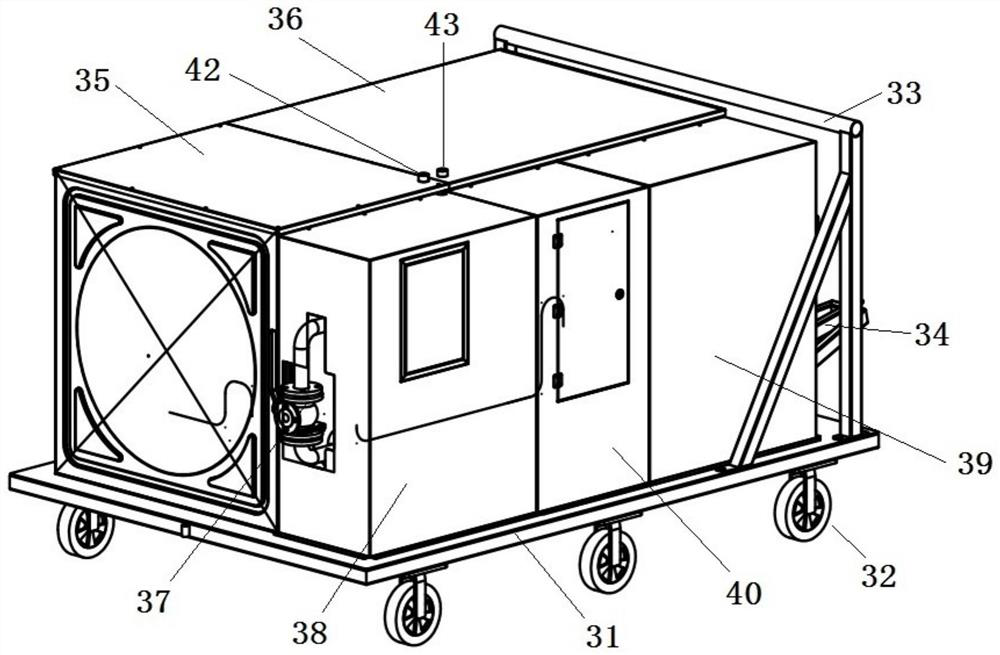

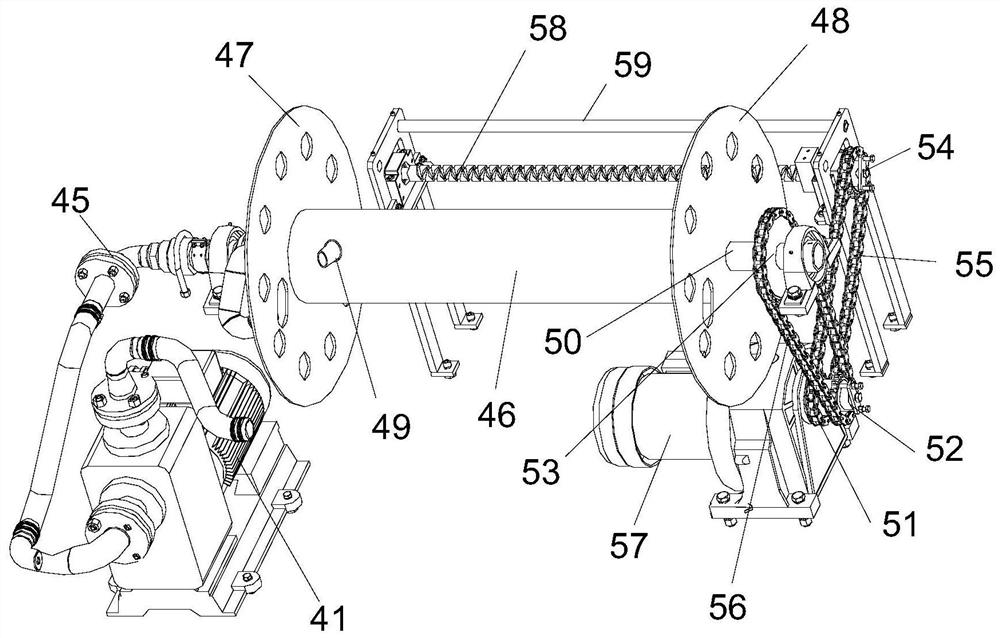

[0067] This embodiment provides a kind of oil pollution transfer vehicle, such as figure 1 and figure 2 As shown, the oil pollution transfer vehicle includes: a chassis 31, an oil storage cabinet 35, a sewage storage cabinet 36, a suction pump mechanism, a pipe retracting mechanism 38, a discharge pump mechanism 39, a fourth shut-off valve 70, and a fifth shut-off valve 71 , and the third control box 40.

[0068] Wherein, the bottom of chassis 31 is equipped with roller 32; The front end of chassis 31 is installed with push rod 33 and draw bar 34. The top of the oil storage cabinet 35 is provided with a first exhaust valve 42; the sewage storage cabinet 36 and the oil storage cabinet 35 are installed side by side on the chassis 31, and the top of the sewage storage cabinet 36 is provided with a second exhaust valve 43. The rollers 32 at the bottom of the chassis 31 facilitate the movement of the chassis 31 and control the movement of the oil pollution transfer vehicle. The ...

Embodiment 2

[0090] A kind of operation control method of oil pollution transfer vehicle, this control method is applied in the oil pollution transfer vehicle in embodiment 1, and control method comprises suction work flow and blowdown work flow; Described suction work flow and blowdown work flow respectively comprise again Oil suction, oil removal; sewage suction, sewage removal four working processes.

[0091] Among them, such as Figure 7 As shown, the control method of the sewage suction process is as follows:

[0092] S1: In the initial state, the oil storage cabinet 35 and the sewage storage cabinet 36 of the oil pollution transfer vehicle are empty; the first exhaust valve 42, the second exhaust valve 43, the fourth stop valve 70, the fifth stop valve 71, the second The self-priming pump 37, the second sewage pump 41, the first motor 57 and the second motor 73 are all in the closed state;

[0093] S2: The operator on the shore gives an instruction to suck sewage to the third contr...

Embodiment 3

[0120] This embodiment provides a ship sewage storage device, such as Figure 9-11 As shown, the device includes a mounting frame 1, a first box body 2, a second box body 3, a liquid level gauge 19, a pulverizing circulation pump 6, an internal circulation pipeline, a cutting sewage pump 10, a sewage pipeline, a first shut-off valve 12, The second stop valve 13 and the third stop valve 24 .

[0121] In this example, a water inlet 4 and an air hole 5 are provided on the top of the first box body 2 . The water inlet 4 is used to communicate with the sewage pipe network on the ship and the inner cavity of the first tank 2 . The air hole 5 is used to balance the air pressure in the first box body 2 and the second box body 3. When the first box body 2 and the second box body 3 receive sewage, the gas in the inner cavity is discharged along the air hole 5. When the first box body 2 and the second box 3 when blowing down, outside air enters along the air holes 5 to balance the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com