Structure and function integrated continuous fiber resin-based wave-absorbing stealth composite material and preparation method thereof

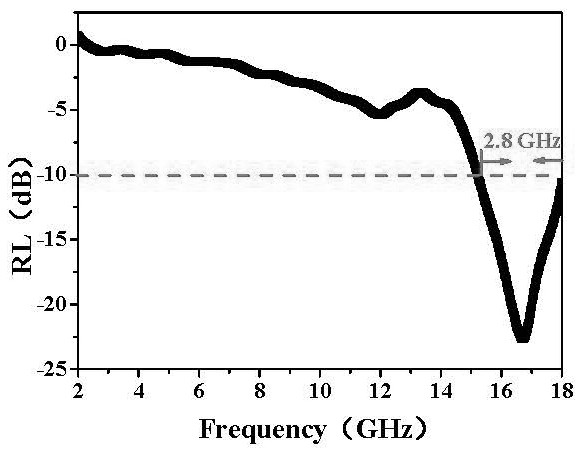

A continuous fiber and composite material technology, applied in the field of microwave absorption composite materials, can solve the problems of large thickness and narrow absorption bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Cut ultra-high molecular weight polyethylene fiber cloth, glass fiber cloth, and carbon fiber cloth to a length×width of 200×200mm, and weigh them to be 8 g, 200 g, and 15 g respectively; the selected length is the length of the cut fiber cloth ( i.e. 200 mm) and a continuous carbon fiber bundle with a width of 2 mm;

[0040] (2) Weigh 87 g of epoxy resin E51 and 48 g of curing agent polyetheramine D400 according to the mass ratio of 1:0.55, mix them evenly, and then put them in a vacuum oven at 85°C for 10 minutes to defoam to obtain the resin glue;

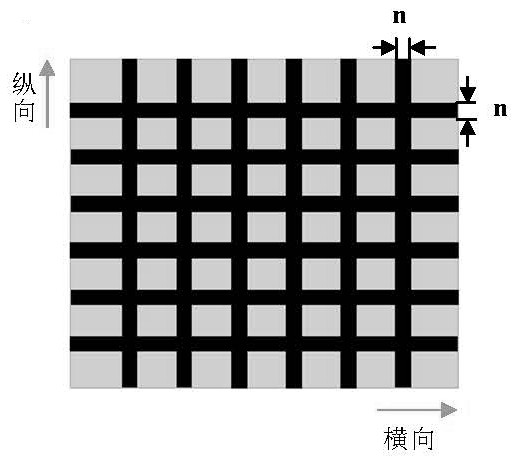

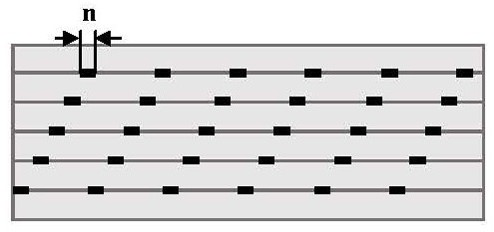

[0041] (3) Lay the glass fiber cloth cut out in (1), and arrange the glass fiber cloth cut out in (1) in a grid arrangement between any two layers of glass fiber cloth at a distance of 10 mm both horizontally and vertically. One bundle of carbon fiber bundles, even if n=2mm, and the carbon fiber bundles on the upper and lower layers of glass fiber cloth are misplaced, specifically, the grid of carbon fiber bundles on ...

Embodiment 2

[0046] (1) Cut ultra-high molecular weight polyethylene fiber cloth, glass fiber cloth, and carbon fiber cloth to a length×width of 200×200mm, and weigh them to be 8 g, 205 g, and 15 g respectively; the selected length is the length of the cut fiber cloth ( i.e. 200mm) and a continuous carbon fiber bundle with a width of 2 mm;

[0047] (2) Weigh 90 g of epoxy resin E51 and 51 g of curing agent polyetheramine D400 according to the mass ratio of 1:0.55, mix them evenly, and then put them into a vacuum oven at 85°C for 10 minutes to defoam to obtain the resin glue;

[0048] (3) Lay the glass fiber cloth cut out in (1), and arrange the glass fiber cloth cut out in (1) in a grid arrangement between any two layers of glass fiber cloth at a distance of 20 mm both horizontally and vertically. Two bundles of carbon fiber bundles, even if n=4mm, and the carbon fiber bundles on the upper and lower layers of glass fiber cloth are misplaced, that is, the grid of carbon fiber bundles on the...

Embodiment 3

[0053] (1) Cut ultra-high molecular weight polyethylene fiber cloth, glass fiber cloth, and carbon fiber cloth to a length×width of 200×200mm, and weigh them to be 7.5 g, 203 g, and 16 g respectively; the selected length is the length of the cut fiber cloth ( i.e. 200 mm) and a continuous carbon fiber bundle with a width of 2 mm;

[0054] (2) Weigh 92 g of epoxy resin E51 and 52 g of curing agent polyetheramine D400 according to the mass ratio of 1:0.55, mix them evenly, and then put them into a vacuum oven at 85°C for 10 minutes to defoam to obtain the resin glue;

[0055] (3) Lay the glass fiber cloth cut out in (1), and arrange the glass fiber cloth cut out in (1) in a grid arrangement between any two layers of glass fiber cloth at a distance of 30 mm both horizontally and vertically. Three bundles of carbon fiber bundles, even if n=6mm, and the carbon fiber bundles on the upper and lower layers of glass fiber cloth are misplaced, that is, the grid of carbon fiber bundles o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum reflection loss | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com