Automatic fan injection mold feeding and discharging gripper based on robot

A technology of automatic loading and unloading and injection molding, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of low production efficiency and high risk, and achieve the effects of improving production efficiency, realizing automation and reducing operational risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

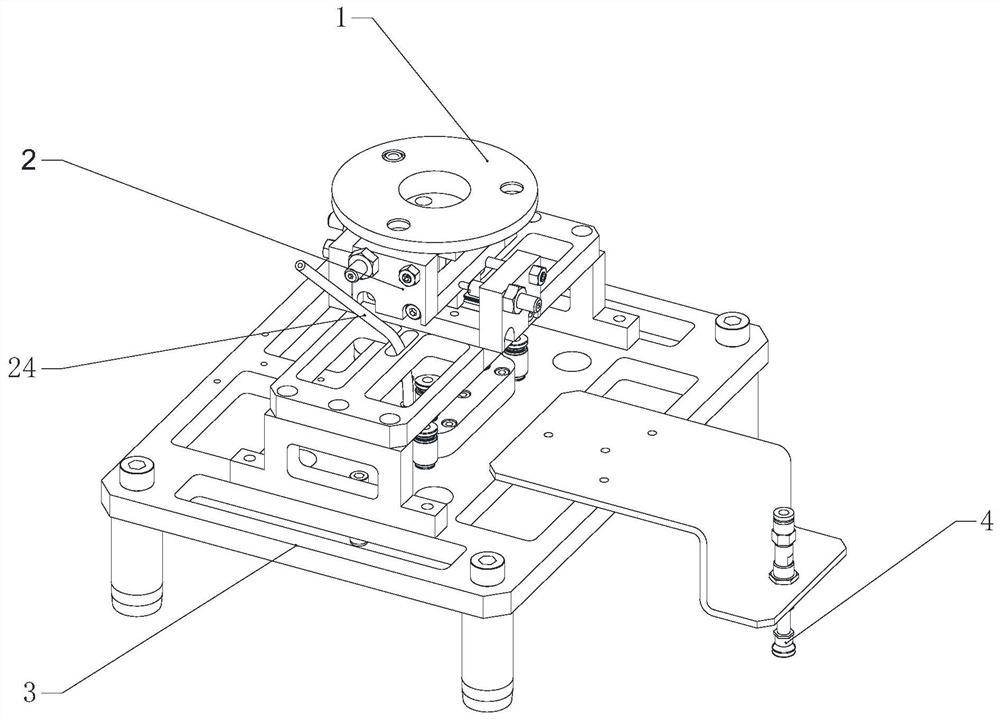

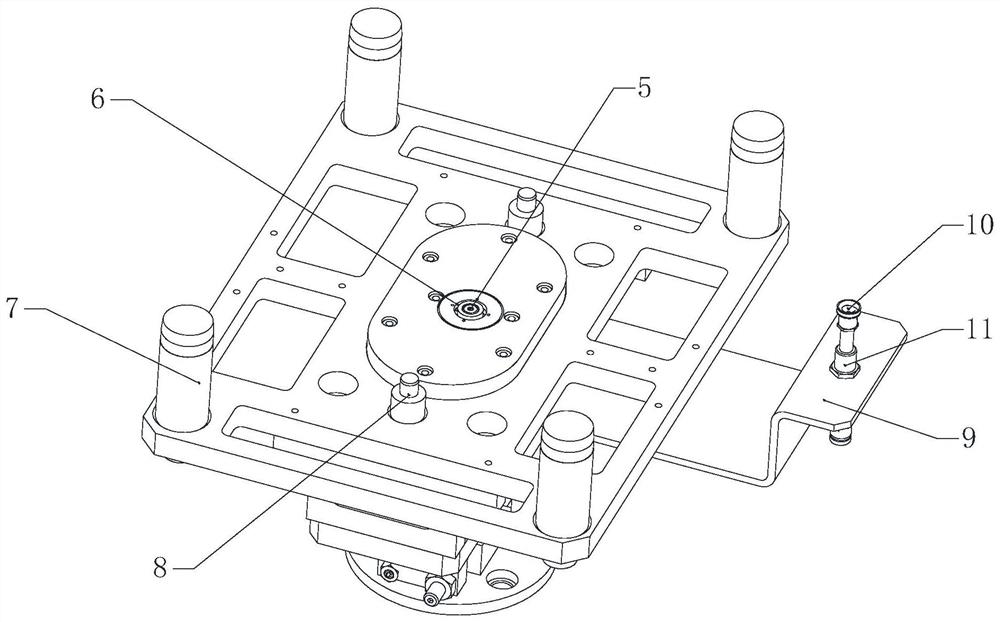

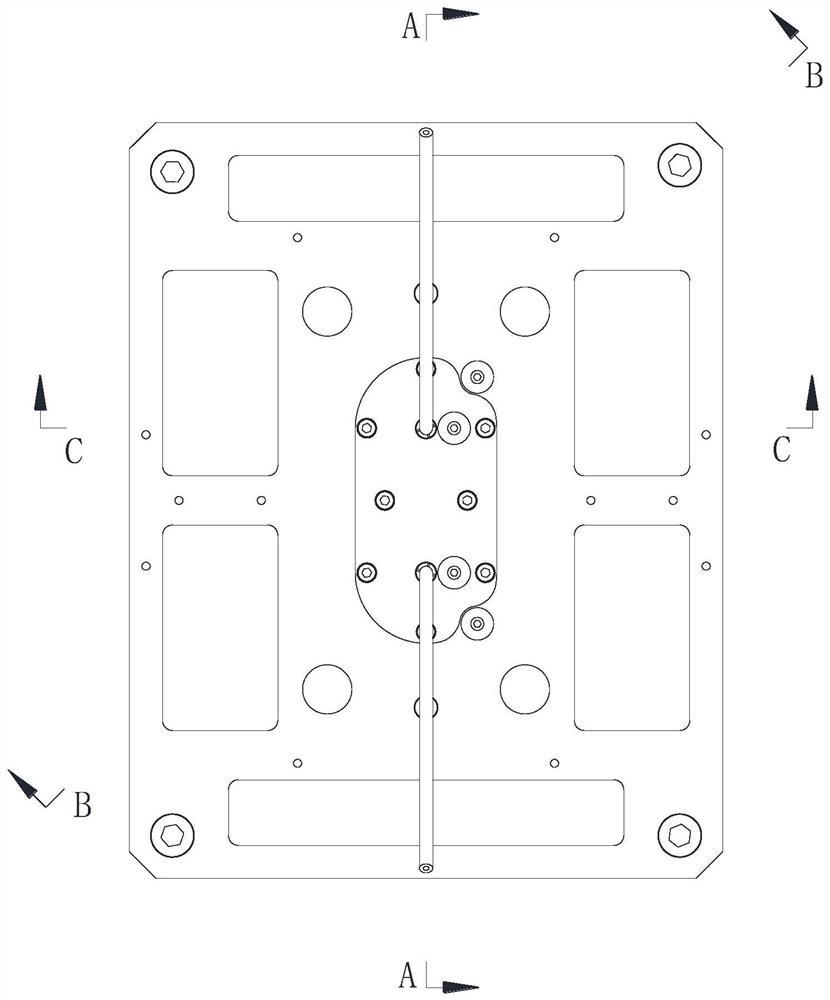

[0041] See Figure 3 to Figure 18 , the present invention consists of a robot mounting flange 1, an XY floating adjustment mechanism 2, a machine base 3, a feeding device 4, a mandrel feeding device 5, a motor shell feeding device 6, a guide shaft 7, and a precision guide shaft 8; The XY floating adjustment mechanism 2 is installed on the upper surface of the machine base 3, and the robot mounting flange 1 is installed on the XY floating adjustment mechanism 2; the motor shell feeding device 6 is installed in the middle of the lower end surface of the machine base 3, and the motor shell is loaded The front and rear sides of the device 6 are symmetrically fixedly connected with a precision guide shaft 8; the unloading device 4 is set at the position corresponding to the mandrel feeding device 5 through the support plate 9 fixedly connected to the machine base 3; the four corners of the machine base 3 are all fixed Connected with guide shaft 7; wherein, there are two sets of unl...

Embodiment 2

[0046] See figure 1 with figure 2 , the present embodiment is basically the same as Embodiment 1, and its distinguishing parts are: the unloading device 4, the mandrel loading device 5 and the motor casing feeding device 6 all have only one set, and the unloading device 4 is composed of a suction cup 10 and a buffer 11 Composition: the suction cup 10 is installed on the buffer 11; the buffer 11 is fixedly connected to the middle position of the support plate 9, and the buffer 11 is set corresponding to the position of the mandrel feeding device 5 .

[0047] The working principle of the present invention is: the machine base 1 is fixedly connected with the guide shaft 7 and the precision guide shaft 8, the guide shaft 7 realizes rough positioning, the precision guide shaft 8 realizes fine positioning, and realizes precise feeding of the mandrel and the motor shell; the mandrel The other end of the feeding hose 24 is connected to the vibrating plate, the mandrel passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com