Material disinfection system and disinfection method

A technology for disinfection of materials and agents, applied in disinfection, conveyor objects, sanitary equipment for toilets, etc., can solve problems such as difficulty in coordinating the negative effects of disinfection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

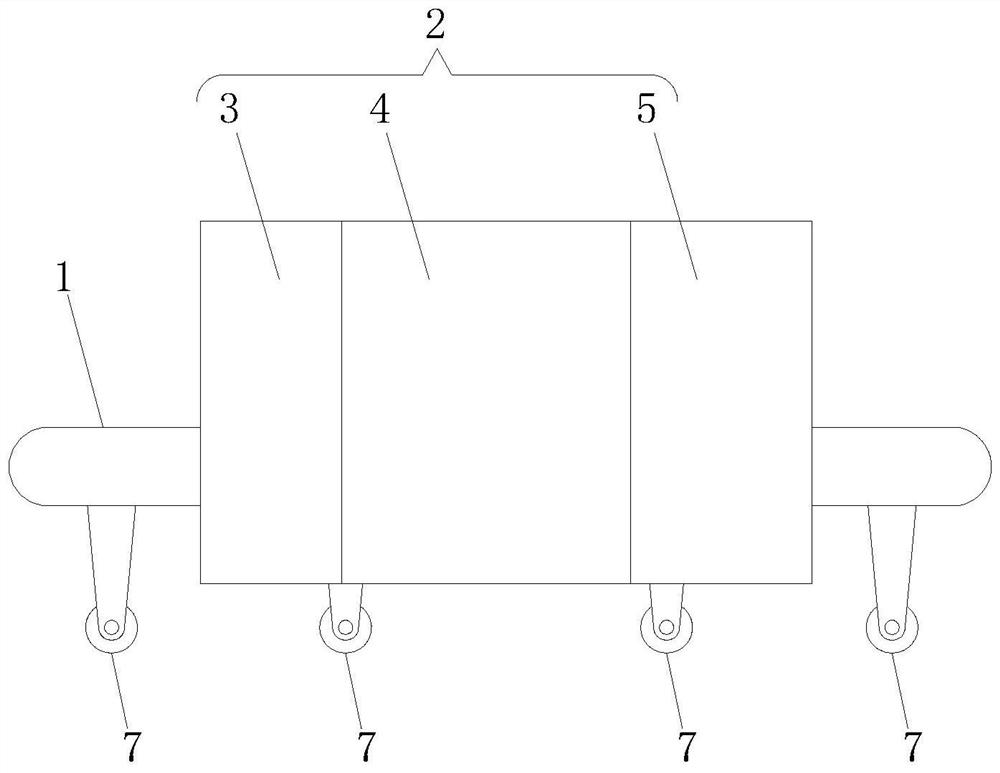

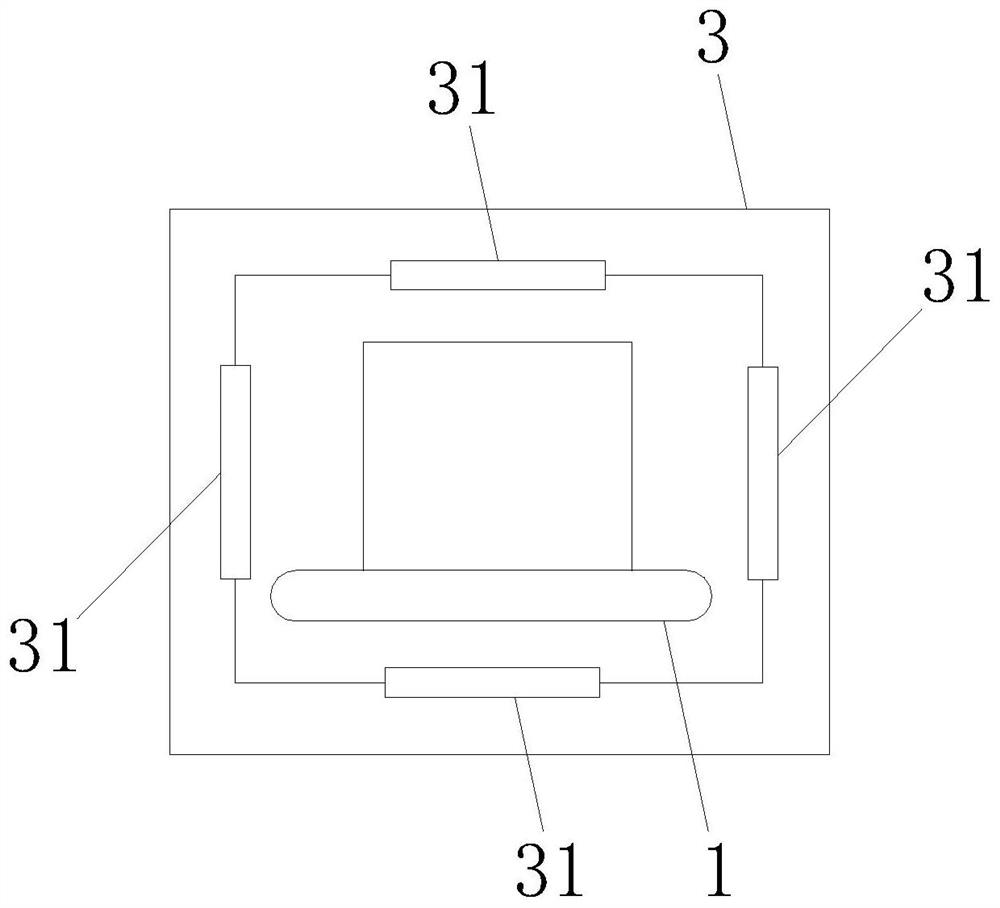

[0039]A material disinfection system, such asFigure 1-5As shown, including the material delivery device 1 and the circumferential annular passage 2 surroundd by the material delivery device, the annular passage 2 includes an ultraviolet disinfectant passage 3, a plasma disinfecting passage 4, and a drug disinfection passage 5. It will be appreciated that the annular passage 2 is "back" hous-like structure, and the material delivery device 1 passes from the hollow portion of the material, and the material delivered by the material delivery device 1 is in the process of passing through the annular passage 2. UV disinfectation passage 3, plasma disinfectation passage 4 and the drug disinfection passage 5 each perform ultraviolet disinfection treatment, plasma disinfection treatment, and drug disinfection treatment. Wherein, the annular passage 2 is used to pass through the material delivery device 1 as a material delivery passage, and the material is moved in the material delivery chan...

Embodiment 2

[0052]A material disinfection method, which is applied to an embodiment of the material disinfection system, which is typically performed by a device having data processing power, such as a computer or controller; of course, can be performed by manual operation through the controller, such asFigure 6 As shown, the method includes the following steps.

[0053]S1, the control material delivery device is operated, and the material to be disprison is fed into the annular passage;

[0054]S2, control the ultraviolet lamp, and ultraviolet disinfection treatment by ultraviolet disinfection channels by ultraviolet rays.

[0055]S3, the control fan and the plasma generator work, and the plasma in the air is placed in the plasma disinfection passage by circulating the wind, and the material of the plasma disinfection passage is plasma disinfection;

[0056]S4, the control pump and the atomizer work, and the pumped agent is discharged through the nozzle, and the drug disinfection treatment is performed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com