Novel plasti- steel composite cable pipeline, and production equipment and production process thereof

A composite cable and production equipment technology, which is applied in the field of new plastic-steel composite cable ducts, production equipment and production technology, can solve the problems of poor connection between the plastic outer layer and the middle reinforcement layer, easy slippage, water leakage, etc., so as to avoid large-area exposure. , It is not easy to take off the wire, and the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]In order to clearly describe the technical characteristics of the present scheme, the present invention will be described in detail by those skilled in the following drawings.

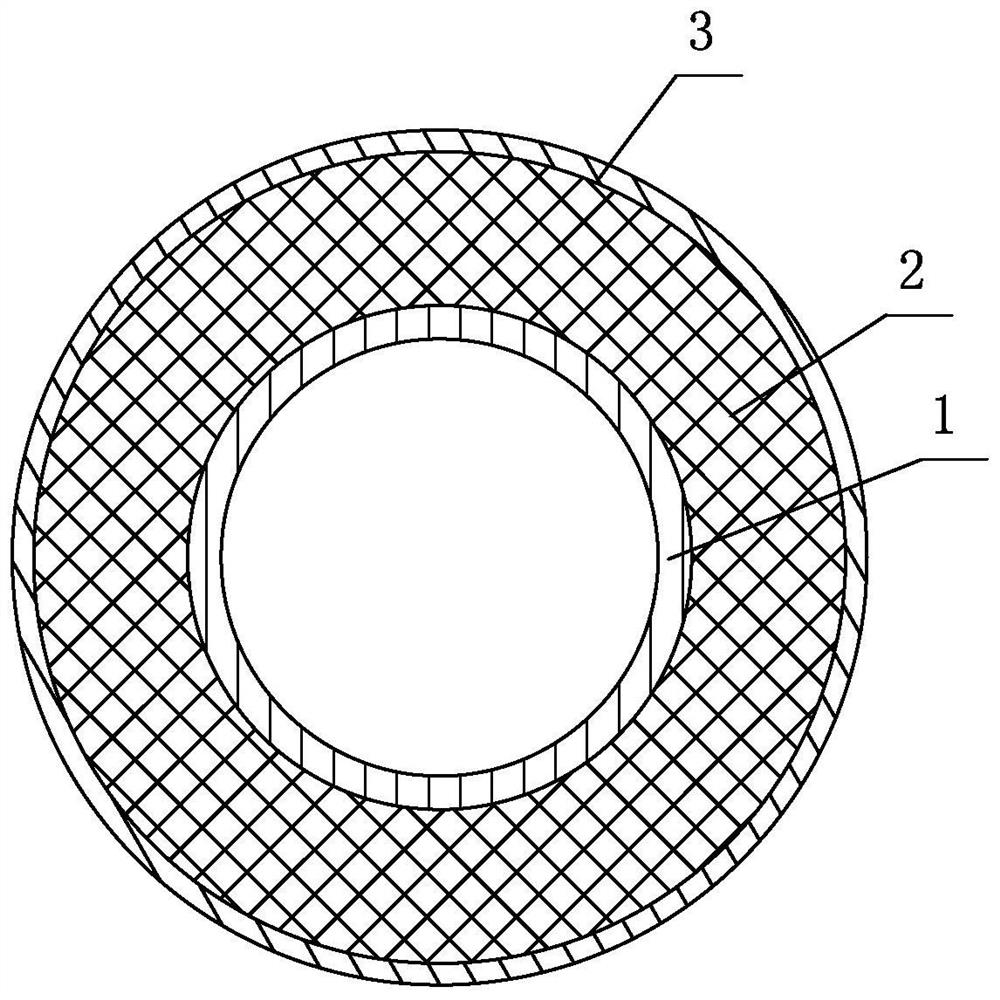

[0039]Such asfigure 1 As shown, a new type of plastic steel composite cable pipe includes:

[0040]Weaving wear layer 1, the braided wear layer 1 is woven by dry fiber, which is within which the cable is laid.

[0041]The structural reinforcing layer 2, the structural reinforcing layer 2 is formed by woven with a dry fiber wire, and a fixed laying composite is formed in the outer surface of the braided abrasion resistant layer 1, and the surface glue of the structural reinforcing layer 2 and penetrates to the interior;

[0042]The coat resin protective layer 3 is firmly formed in the outer surface of the structural reinforcing layer 2, and is a waterproof cable tube that is reliably resistant to the outer surface of the structural reinforcing layer 2.

[0043]The fiber is made of glass fibers or basalt fibers or carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com