Steel plate corner detection method and system under complex background

A corner detection and complex background technology, applied in the field of image processing, can solve problems such as incomplete outlines of vertices, large interference, poor performance, etc., and achieve the effect of convenient deployment and low computer computing power requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

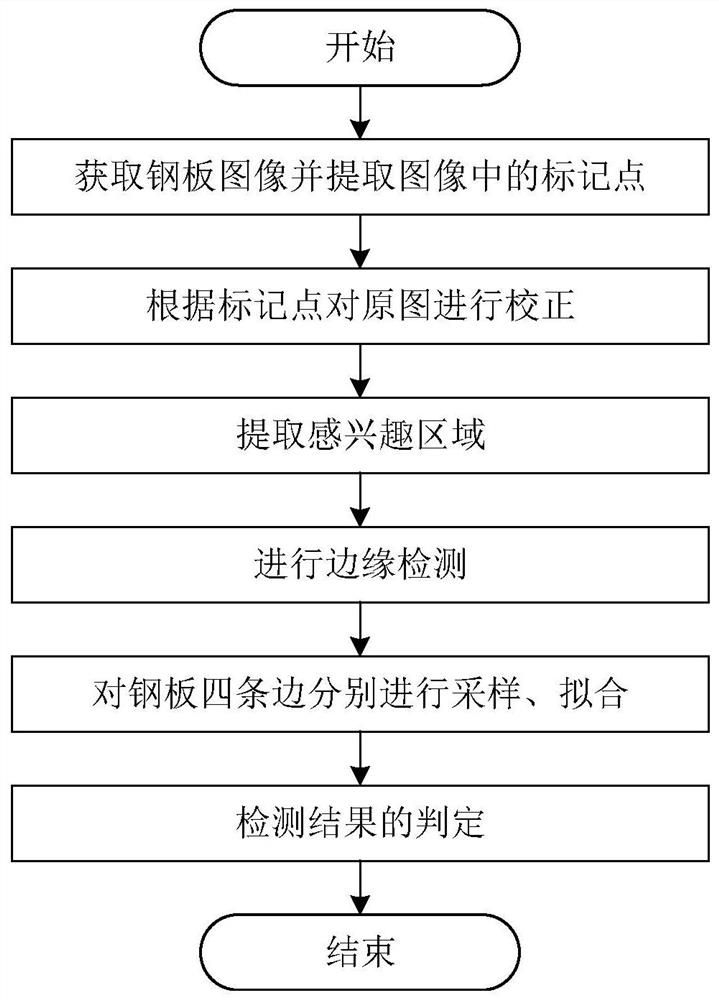

[0064] The implementation steps of the embodiment of the present invention are as follows:

[0065] Step 1: Obtain the steel plate image and extract the marked points in the image;

[0066] Step 2: Correct the image;

[0067] Step 3: Extract the region of interest;

[0068] Step 4: Perform edge detection;

[0069] Step 5: Sampling and fitting the four sides of the steel plate;

[0070] Step 6: Judging the detection results.

[0071] The flow process of the embodiment of the present invention is as figure 1 As shown, the specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0072] Step 1. Get the steel plate image and extract the marker points in the image:

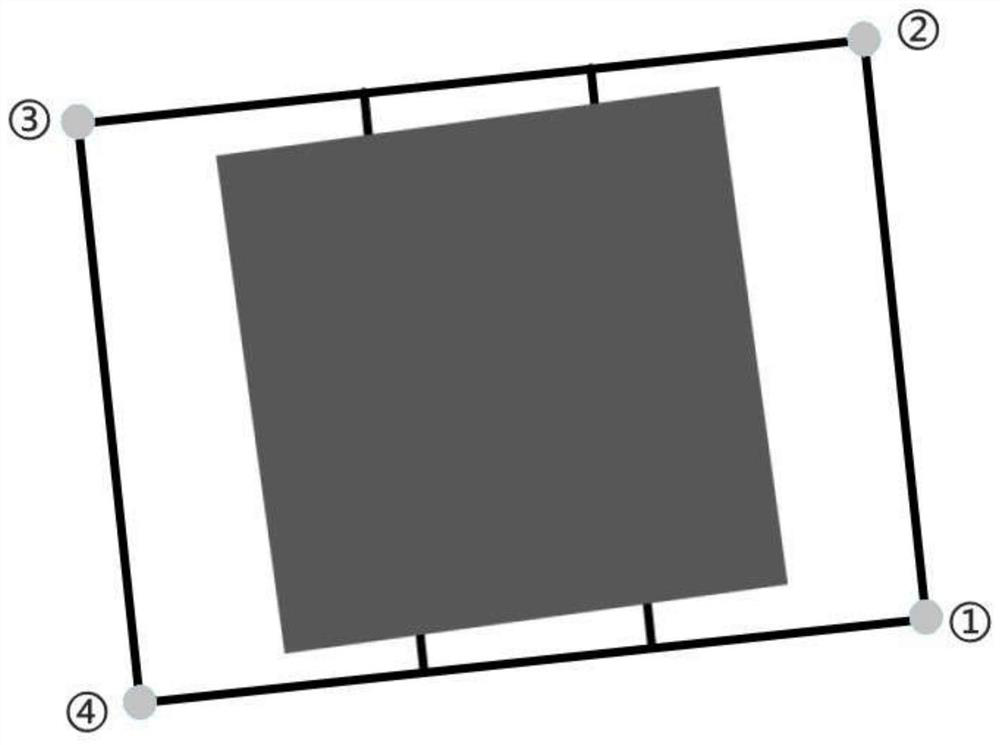

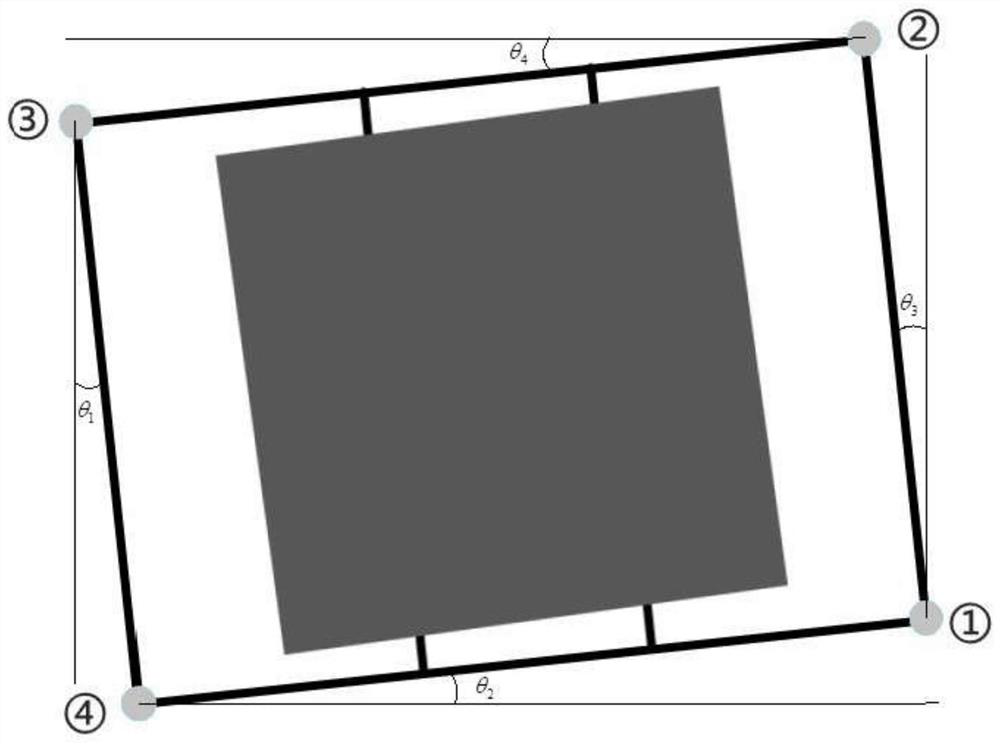

[0073] Hikvision industrial cameras are used to collect images of the steel plate, and the steel plate is shot vertically down from the top to obtain the image. Steel plate processing scene such as figure 2 As shown in , set a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com