A kind of thin-film lithium niobate electro-optic modulator and preparation method thereof

An electro-optic modulator and lithium niobate technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of high loss of thin-film lithium niobate modulators, high manufacturing process requirements, and large driving voltage, so as to avoid microwave loss , increase the overlapping area, reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

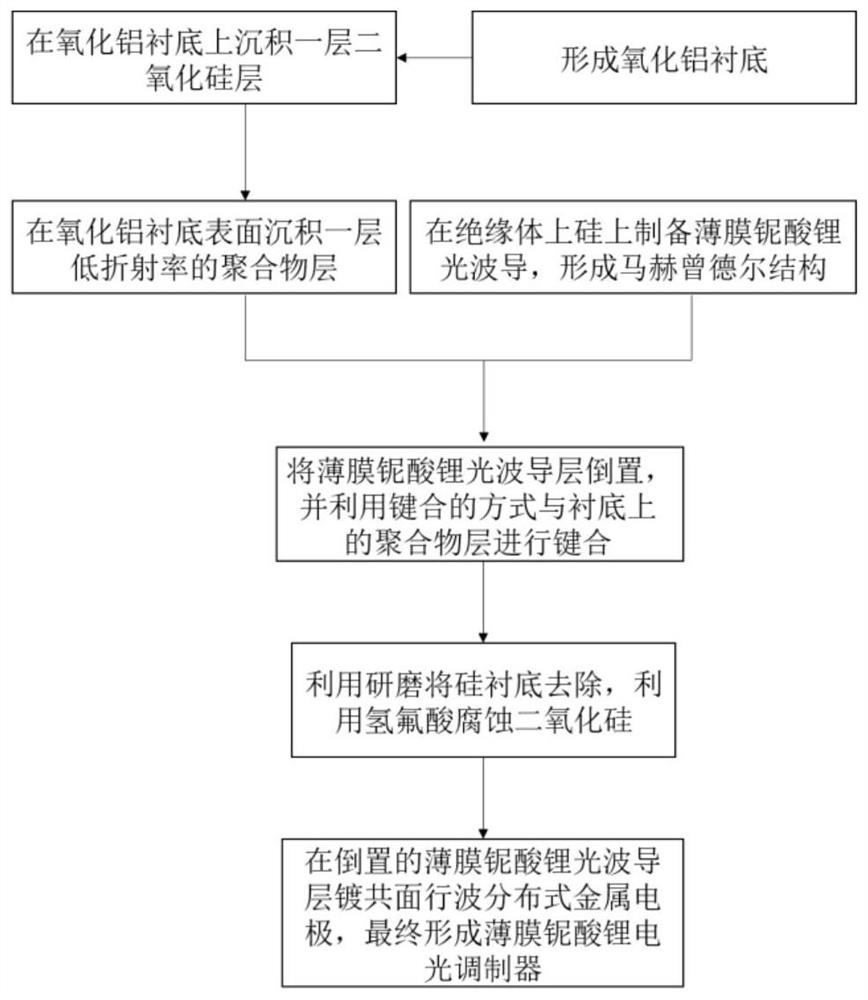

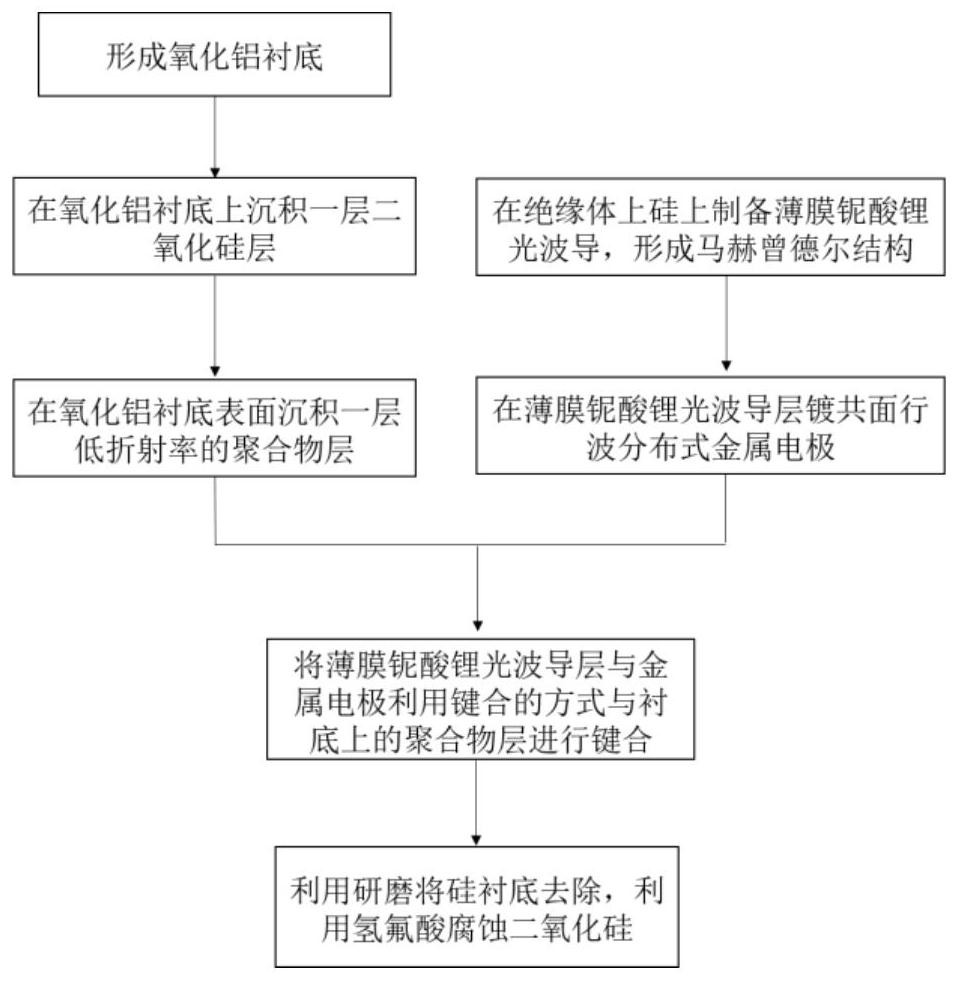

Method used

Image

Examples

Embodiment 1

[0066] like Figure 8 As shown, this embodiment includes a substrate 1, a buried oxide layer 2, a polymer layer 3 and an optical waveguide layer 4 arranged in sequence from bottom to top, [that is, the buried oxide layer 2 is placed on the substrate 1, and the polymer layer 3 is placed on the substrate 1. On the buried oxide layer 2 , the optical waveguide layer 4 is placed on the polymer layer 3 . 】

[0067] A metal signal electrode 6 and a metal ground electrode 7 are arranged on the optical waveguide layer 4, [the metal signal electrode 6 and the metal ground electrode 7 are placed on the optical waveguide layer 4;] the bottom surface of the optical waveguide layer 4 is arranged to form a 1*2 beam splitter 8, Mach-Zehnder modulator 9 and 2*1 beam combiner 10, 1*2 beam splitter 8 and 2*1 beam combiner 10 are located on both sides of Mach-Zehnder modulator 9, and 1*2 beam splitter The two output ends of the beam splitter 8 are connected through the Mach-Zehnder modulator 9 ...

Embodiment 2

[0084] like Figure 9 As shown, this embodiment includes a substrate 1, a buried oxide layer 2, a polymer layer 3 and an optical waveguide layer 4 arranged in sequence from bottom to top, [that is, the buried oxide layer 2 is placed on the substrate 1, and the polymer layer 3 is placed on the substrate 1. On the buried oxide layer 2 , the optical waveguide layer 4 is placed on the polymer layer 3 . 】

[0085] A metal signal electrode 6 and a metal ground electrode 7 are arranged in the polymer layer 3 under the optical waveguide layer 4. [The metal signal electrode 6 and the metal ground electrode 7 are placed on the optical waveguide layer 4 and the polymer layer 4 below the Between layers;] 4 bottom surfaces on the optical waveguide layer are arranged to form 1*2 beam splitter 8, Mach-Zehnder modulator 9 and 2*1 beam combiner 10, 1*2 beam splitter 8 and 2*1 beam combiner 10 is located on both sides of the Mach-Zehnder modulator 9, and the two output ends of the 1*2 beam sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com