High-low temperature bending test device for pipe

A technology of high and low temperature test chamber and bending test, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, which can solve the problem that it is difficult to simulate the use of TPU pneumatic tubes and cannot well reflect the real performance of TPU pneumatic tubes. and other problems to achieve the effect of improving test efficiency and versatility, controllable test conditions, and ensuring stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

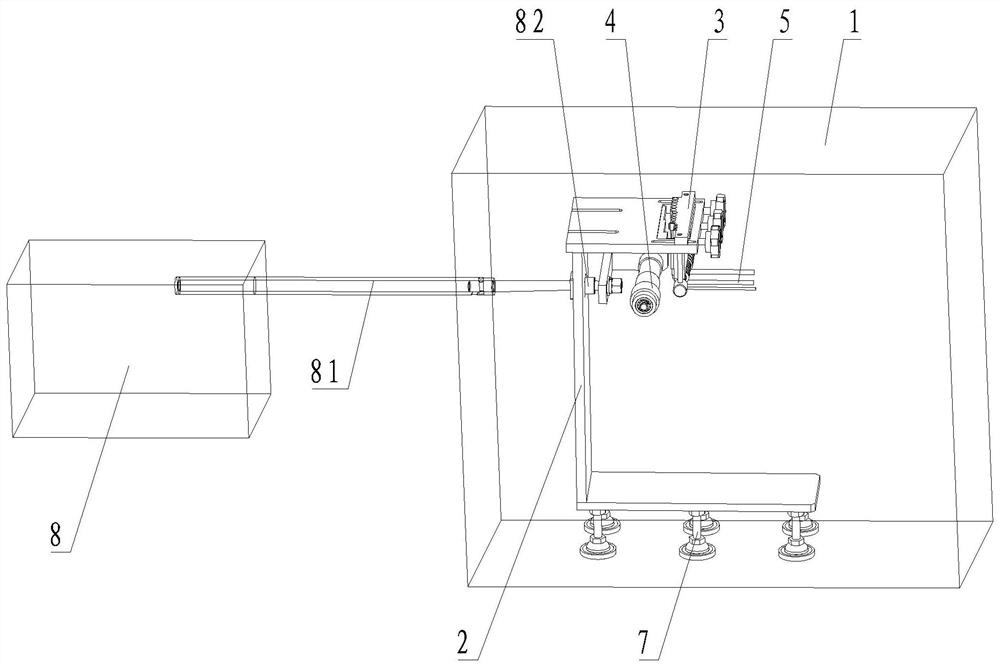

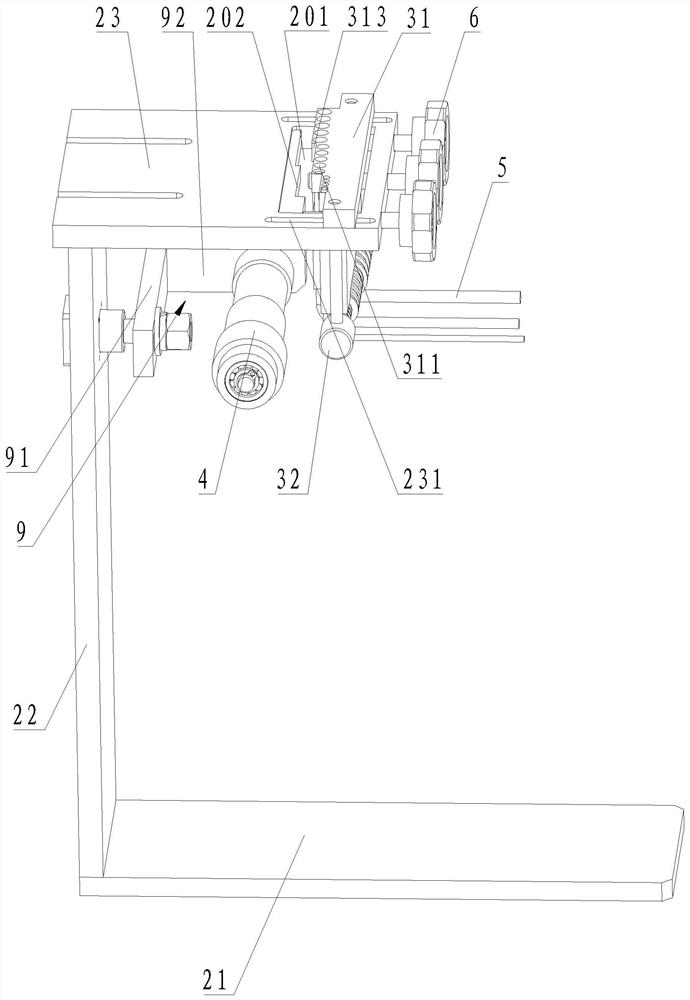

[0044] A high and low temperature bending test device for pipes, such as figure 1 and figure 2 As shown, it includes a high and low temperature test box 1, a support frame 2, a locking pipe fitting 3 and a roller 4. The support frame 2 is arranged in the high and low temperature test chamber 1; the locking pipe fitting 3 is arranged on the support frame 2 for fixing the pipe material 5; 4 is arranged on the support frame 2 and located below the lock pipe 3 , the roller 4 can move back and forth along the first direction, and is used to bend or loosen the pipe 5 protruding from the bottom of the lock pipe 3 .

[0045]Specifically, the high and low temperature test chamber 1 is a casing that can produce high temperature conditions and low temperature conditions. In actual use, a suitable high and low temperature test chamber 1 can be selected according to the high temperature and low temperature required for the test, such as the test conditions of the present invention. The h...

Embodiment 2

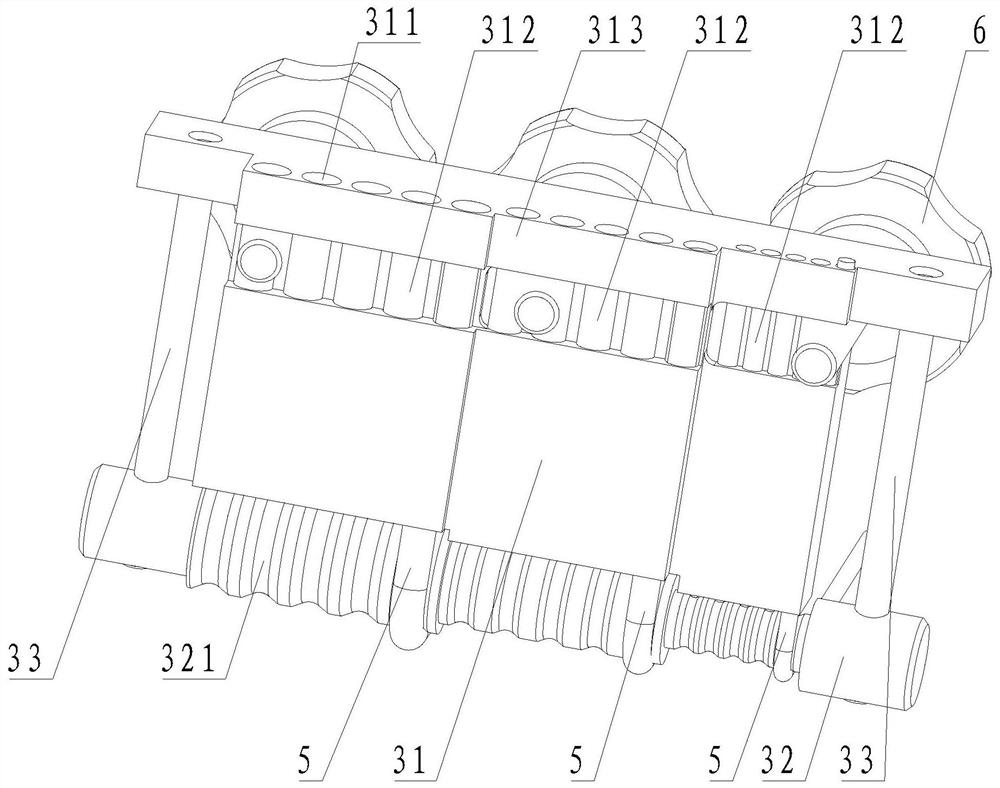

[0062] On the basis of the first embodiment above, as Figure 4 As shown, the guide rod 32 in this embodiment is a multi-stage stepped rod, the roller 4 is a multi-stage stepped roller, and the direction in which the diameter of the guide rod 32 increases in the axial direction is opposite to the direction in which the diameter of the roller 4 increases in the axial direction. The guide rod 32 and the roller 4 are arranged in a multi-step form, so that the roller 4 and the guide rod 32 can simultaneously bend pipes 5 of different diameters to test pipes 5 of different specifications, improving the testing efficiency and versatility of the test device.

[0063] Exemplary, such as Figure 4 As shown, the guide rod 32 includes a first-stage guide rod 322, a second-stage guide rod 323, and a third-stage guide rod 324 whose diameters increase sequentially. Roller 42 and third stage roller 43 , first stage guide rod 322 corresponds to third stage roller 43 , second stage guide rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com