Recovery device for extracting metal from acid-making high-iron cinder and use method thereof

A technology for metal extraction and recovery device, applied in the field of slag metal recovery device, can solve the problems of low metal extraction rate, slag agglomeration, insufficient combustion of high-speed iron slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

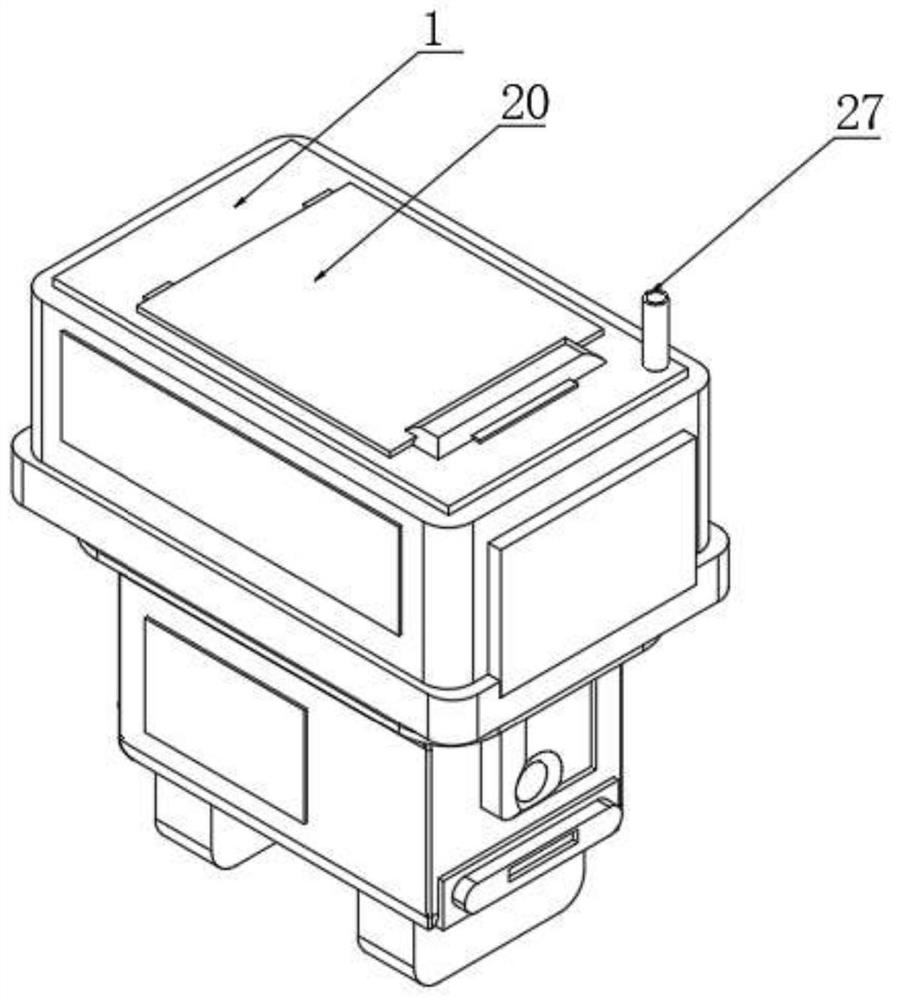

[0039] The present invention provides a recovery device for extracting metals from acid-making high iron slag, which comprises a casing 1, a combustion chamber 2 is provided inside the casing 1, and a supporting mechanism is provided inside the combustion chamber 2;

[0040] The support mechanism includes at least two support plates 3, and the support plates 3 are provided with through holes 4, and the through holes 4 are successively reduced from top to bottom, so that different sizes of slag raw materials can be layered Combustion, so that the slag raw materials can be burned more fully;

[0041] The support plate 3 includes a fixed plate 5 connected to the inner wall of the combustion chamber 2, a moving plate 6 is arranged above the fixed plate 5, the top of the through hole 4 is connected to the moving plate 6, and the bottom of the through hole 4 is connected to the fixed plate. connected to the plate 5, and the inside of the through hole 4 contains a telescopic layer 7....

Embodiment 2

[0051] The difference with embodiment 1 is:

[0052] The feeding mechanism includes a feeding plate 21, the feeding plate 21 is inclined, the bottom of the inclined end of the feeding plate 21 is provided with a transmission mechanism, and the end of the feeding plate 21 away from the transmission mechanism is connected to the inner wall of the cavity through a rotating shaft. An adsorption mechanism is arranged above the feeding plate 21, and the transmission mechanism includes a connecting rod 22 hinged with the feeding plate 21. The other end of the connecting rod 22 is hinged with a cam 23. Connected driving motor 24, the connecting rod 22 includes a first rod body and a second rod body, the connecting ends of the first rod body and the second rod body are connected by a rotating shaft, the adsorption mechanism includes an adsorption plate 25, and the adsorption plate 25 is arranged in parallel with the feeding plate 21, the adsorption plate 25 is made of electromagnet mat...

Embodiment 3

[0061] All different from embodiment 1 and embodiment 2:

[0062] Both ends of the moving plate 6 are provided with guide grooves 26 inclined toward the middle, and a pipe body 27 communicating with the combustion chamber 2 is provided above the housing 1 to reuse the emitted heat. One side of the driving wheel 8 An auxiliary wheel 28 is fixedly arranged, and the auxiliary wheel 28 is attached to the roller 10 to assist positioning left and right.

[0063] A method for extracting metals from high-iron acid slag, characterized in that it comprises the following steps:

[0064] Step 1: Open the opening plate 20 to place the slag raw material in the combustion chamber 2, and burn the slag raw material through the combustion burner in the combustion chamber 2;

[0065] Step 2, the output shaft of the reduction motor 16 can rotate with the driving wheel 14, and the driving wheel 14 can drive several driven wheels 13 to rotate through the transmission belt 15 which is socketed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com