Cotton filling gun for glass fiber puffing

A technology of glass fiber and shell, which is applied in the field of cotton filling gun for glass fiber puffing, which can solve the problems of affecting heat preservation and noise reduction effect, uneven dispersion of glass fiber, etc., and achieves the effect of ensuring stability, easy positioning, and ensuring dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

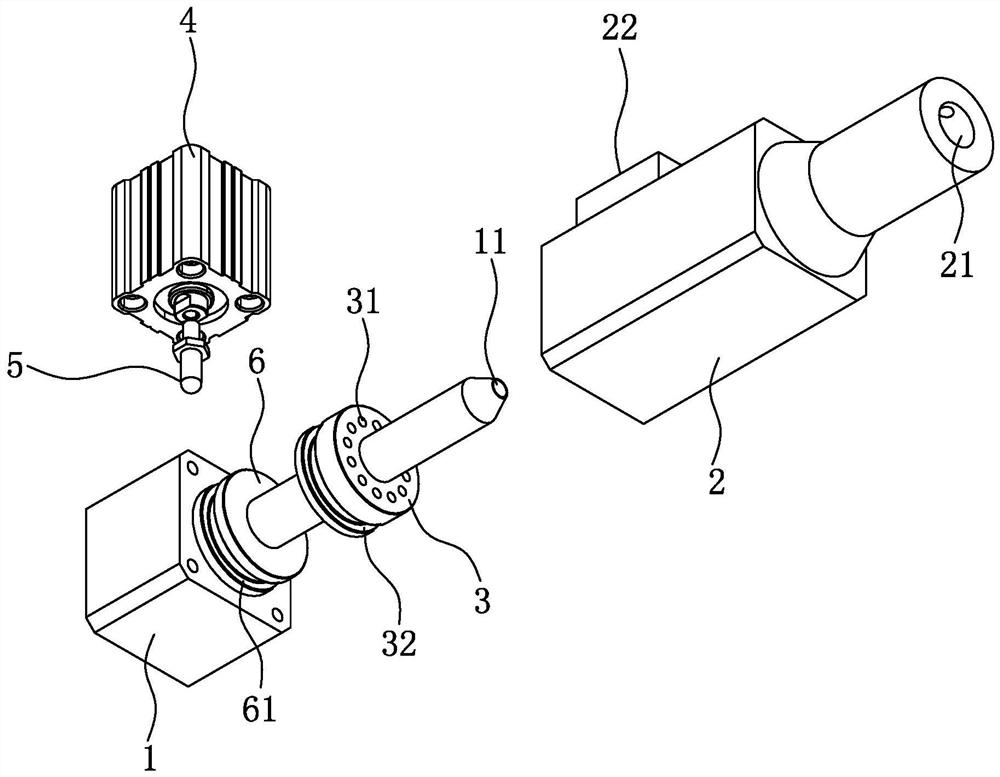

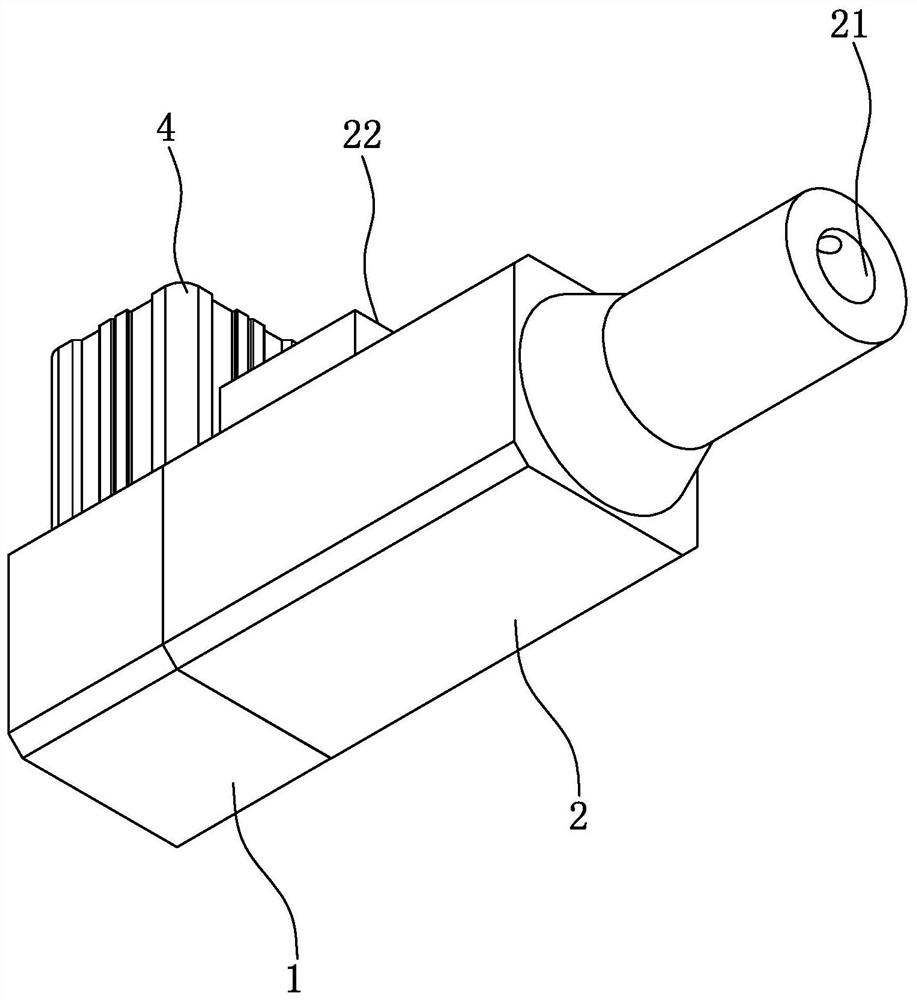

[0030] The following is attached figure 1 The application is described in further detail.

[0031] The embodiment of the present application discloses a cotton-filled gun for expanding glass fibers. Such as figure 1 with figure 2 As shown, the cotton filling gun for glass fiber expansion includes a base body 1 , a casing 2 and a cylinder 4 fixed on the base body 1 . One end of the base body 1 is inserted into the housing 2, the base body 1 and the housing body 2 are fixed and sealed, and the base body 1 is provided with a threading hole 11 through which glass fibers are penetrated along the length direction of the base body 1, and the housing body 2 is formed There is an inner cavity 21, and the glass fiber passes through the threading hole 11 and the inner cavity 21. One end of the seat body 1 located in the housing 2 is arranged at a uniform gap with the inner wall of the housing 2 to form a high-pressure gas outlet. The base 1 is provided with a partition plate 3 perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com