High-strength light-weight carriage plate and preparation method thereof

A lightweight, carriage board technology, applied in chemical instruments and methods, vehicle components, superstructures of trucks, etc., can solve problems such as decreased bonding strength of boards and inadequate dipping, and achieve enhanced bonding strength and improvement. Load-carrying properties, the effect of improving the degree of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

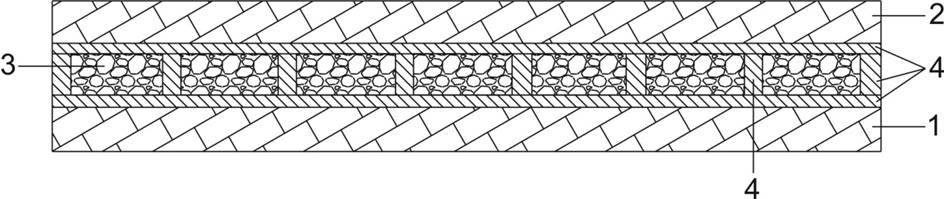

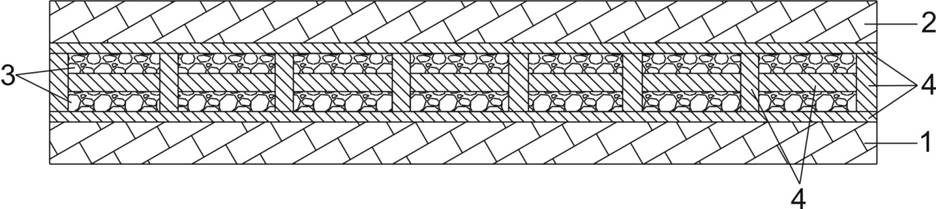

[0040] Such as figure 1 Shown, a kind of high-strength lightweight car panel, comprises first panel layer 1, second panel layer 2, sandwich layer, skeleton support layer 4, and described sandwich layer is a layer of foam layer, and this foam layer is made of several The cuboid foam blocks 3 are spliced together; the sandwich layer is arranged between the first panel layer 1 and the second panel layer 2, between the lower surface of the sandwich layer and the first panel layer 1, the upper surface of the sandwich layer and Between the second panel layer 2, the surrounding (front, back, left, and right) edges of the sandwich layer, and the joints of any two adjacent foam blocks 3 in the sandwich layer are integrally solidified and filled with a skeleton support layer 4; the skeleton support layer 4 and the second A panel layer 1 and a second panel layer 2 are integrally cured and molded; the first panel layer 1 and the second panel layer 2 are both glass fiber reinforced unsat...

Embodiment 2

[0049] A high-strength and lightweight car panel, the structure of which is different from that of Example 1 is that the skeleton support layer 4 is a foamed resin-based composite material, and the foamed resin-based composite material is unsaturated polyester resin and hollow Glass microspheres are obtained by curing; the difference between the preparation method and Example 1 is that no expandable microsphere foaming agent is added in step (1), and the composite foam premix is unsaturated polyester resin, hollow glass microspheres , curing agent and accelerator are obtained by mixing in a mass ratio of 100:20:20:2.

[0050] The density of the compartment board prepared in this embodiment is 0.26 g / cm 3 , with a compressive strength of 4.7 M pa.

Embodiment 3

[0052] A high-strength and lightweight vehicle box panel, the structure is different from that of Example 1 in that: the skeleton support layer 4 is a foamed resin-based composite material, and the foamed resin-based composite material is unsaturated polyester resin and The expansion microsphere foaming agent is obtained by curing; the difference between the preparation method and Example 1 is that no hollow glass microspheres are added in step (1), and the composite foam premix is unsaturated polyester resin, expandable microspheres The foaming agent, the curing agent and the accelerator are mixed in a mass ratio of 100:2:20:2.

[0053] The density of the compartment board prepared in this embodiment is 0.27 g / cm 3 , with a compressive strength of 4.5 M pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com