Proportioning device for super-retarded concrete and proportioning process thereof

A concrete and ultra-retarding technology, which is used in clay preparation devices, mixing operation control devices, batching and batching instruments, etc., can solve the problems of concrete not meeting the requirements of the construction site, save time, have good workability, and improve the proportioning ratio. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

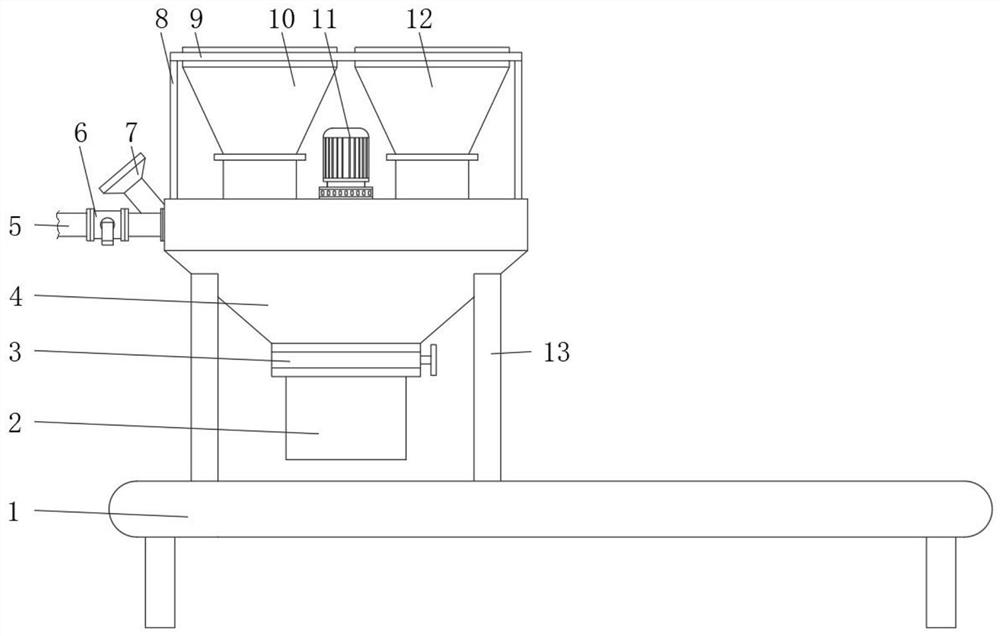

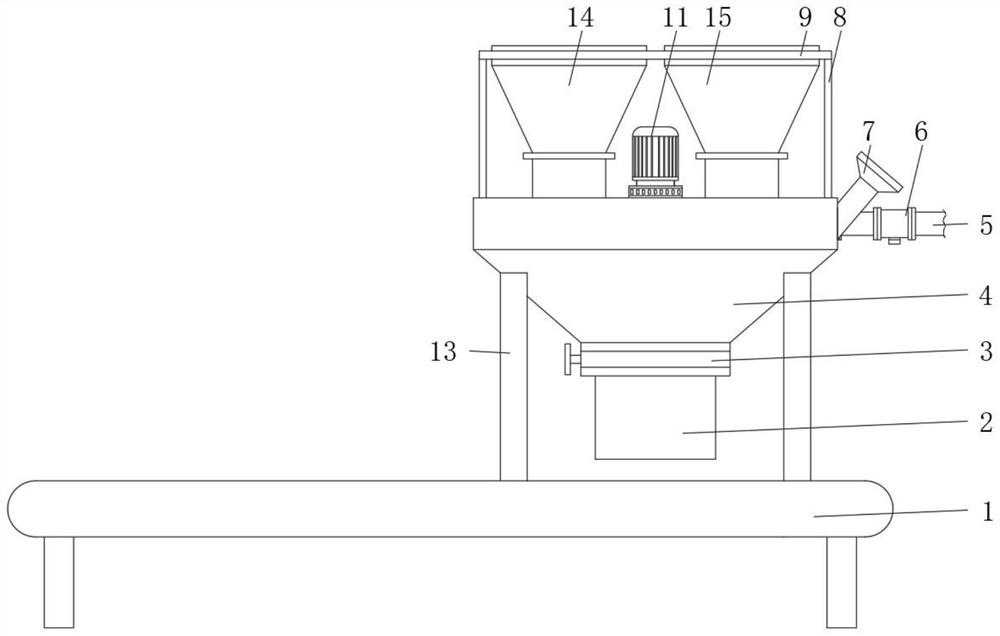

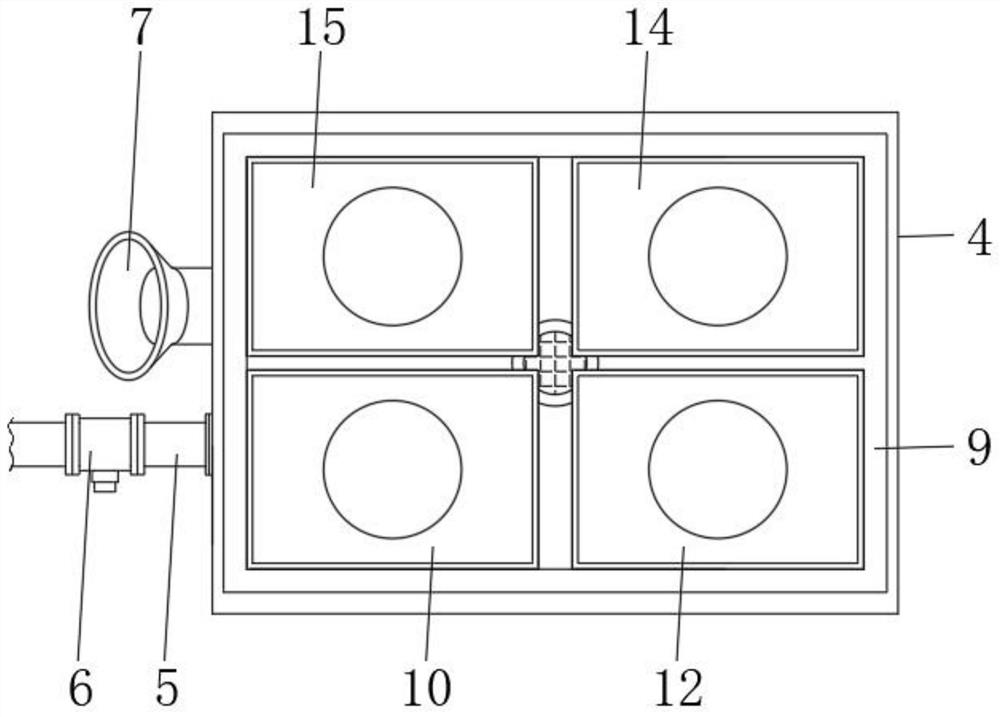

[0033]Seefigure 1 ,figure 2 withimage 3 In the present invention, an embodiment of the present invention is: a comparison device of a supercond concrete comprising a conveyor body 1, a lower air passage 2, a mixing tank 4, and a fixed frame 9, and a conveyor body 1 is driven on a conveyor belt. The conveyor belt is driven by a motor. As is well known to those skilled in the art, the delivering of the conveyor body 1 is used to conventionally, and it is common to conventionally or known common sense, and will not be described later, and those skilled in the art can make any optional or convenient. The front and rear two ends of the on-surface side of the conveyor body 1 are welded to the rectangular array, and the top ends of the four second pillars 13 are welded to the bottom of the mixing tank 4, respectively, and the upper surface of the mixed box 4 is in turn. Fixed the first hopper 10, the second hopper 12, the third hopper 14 and the fourth hopper 15, the first hopper 10, the s...

Embodiment 2

[0036]Seefigure 1 ,figure 2 withFigure 4 In one embodiment of the present invention, a comparison device of a supercond concrete is fixed, and there is a drive motor 11 in the upper surface of the mixing tank 4, as is well known to those skilled in the art, and the driving motor 11 provides Siki, It belongs to a routine means or known common sense, and will not be described later, and those skilled in the art can make any optional or convenient. The bottom end of the drive motor 11 is rotated and mounted with stirring rod 16, and the stirring lever 16 extends into the mixing tank 4, and the stirring lever 16 is welded to be stirred. After all the raw materials are inserted into the mixing box 4 in accordance with the ratio, the drive motor 11 is turned on, and the stirring lever 16 is rotated under the drive motor 11, and the stirred leaf 17 is rotated as the stirring rod 16, by rotating the stirred blade 17 pair The raw materials in the mixing tank 4 were stirred so that the raw ma...

Embodiment 3

[0038]Seefigure 1 ,figure 2 withFigure 5In one embodiment of the present invention, a comparison device of a super-sleeper concrete is fixed at the bottom outlet of the mixing case 4, and the lower surface of the lower surface and the lower surface of the lower surface passage 2 are welded to the lower surface. The passage 2 bottom discharge port corresponds to the conveyor belt on the conveyor body 1. The mixed material after mixing tank 4 is discharged on the conveyor belt of the conveyor body 1 by the lower air passage 2. The inside of the lower oriented passage 2 has four partitions 18, and the material is separated by the separator 18 in the lower air passage 2, and the discharged material is distributed more uniform on the conveyor body 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com