Positioning high-precision cutting and recycling equipment for plastic material processing

A recovery equipment and high-precision technology, which is applied in metal processing and other directions, can solve the problems of inconvenient continuous operation of equipment, inability to automatically control the lifting and lowering of cutting knives, and inconvenient adjustment of plastic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

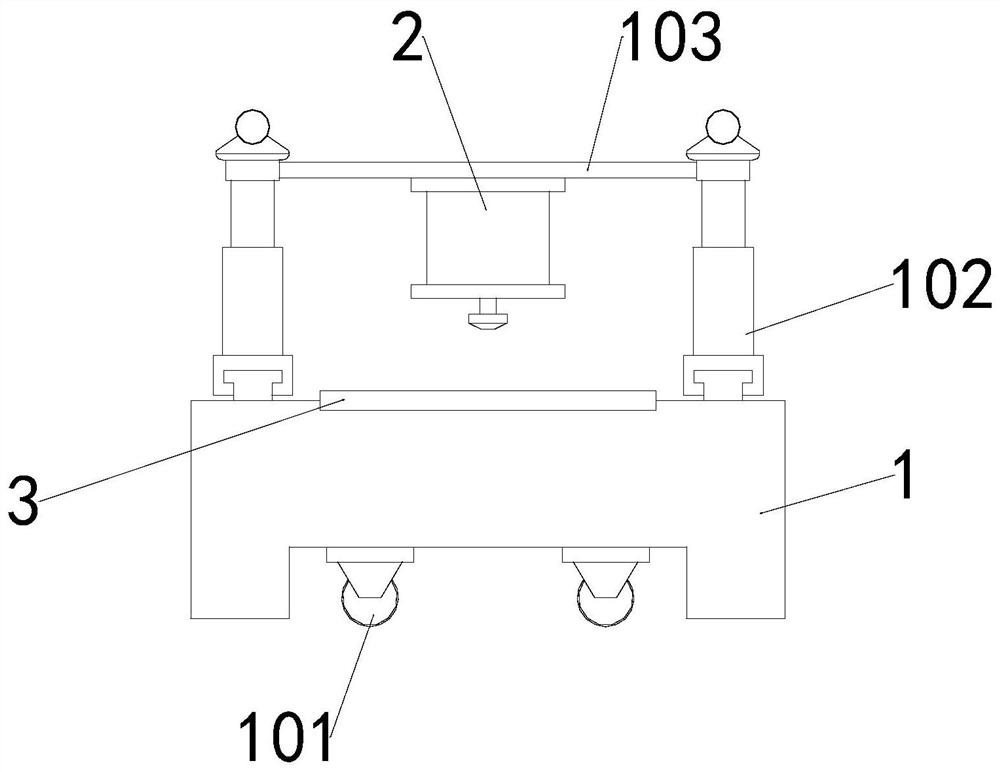

[0030] see Figures 1 to 11 Among them, in an embodiment of the present invention, a positioning high-precision cutting and recycling device for plastic material processing includes: a device body 1, a support column 102 and a top plate 103, and both ends of the top of the device body 1 are equipped with support columns 102, and the two A top plate 103 is installed between the tops of the support columns 102, the bottom of the top plate 103 is provided with a cutting mechanism 2, and the inner top of the equipment body 1 is provided with a limit mechanism 3, and the bottom of the equipment body 1 is equipped with two road wheels 101.

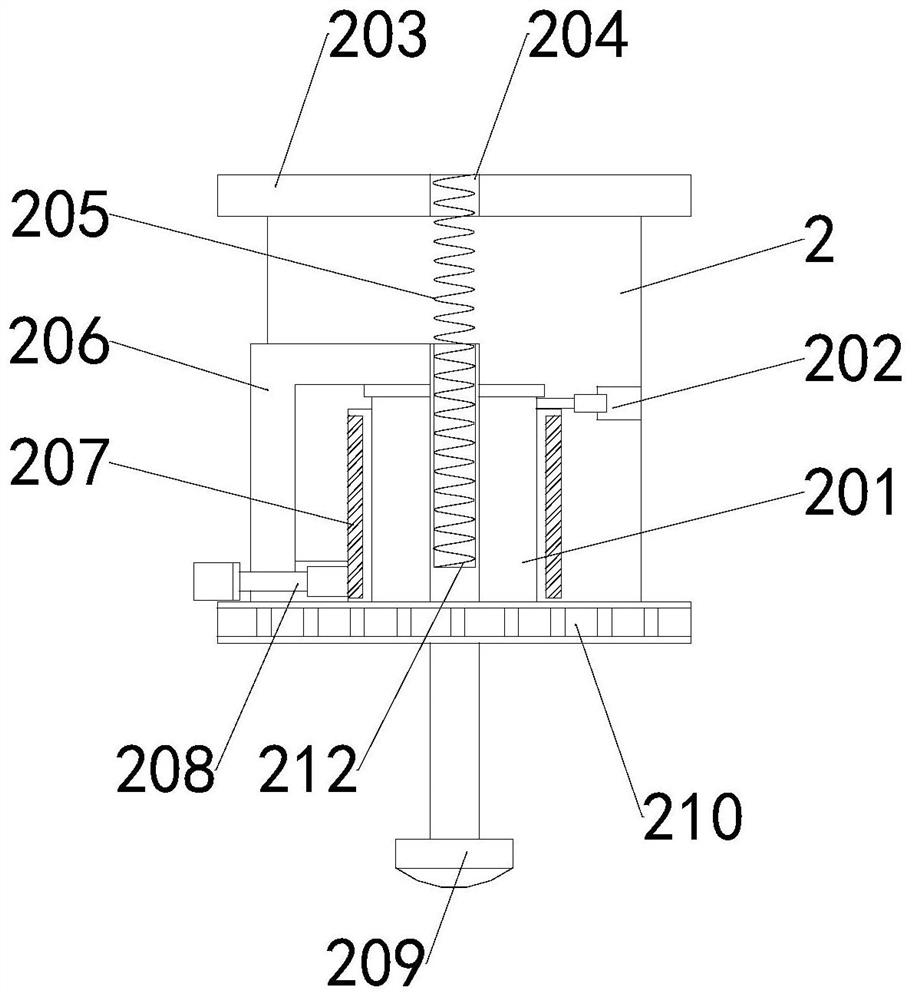

[0031] Wherein, the cutting mechanism 2 includes: a rotating plate 210 and a vertical cylinder 201, the rotating plate 210 is fixedly connected to the bottom of the cutting mechanism 2, and the top of the cutting mechanism 2 is provided with a fixed plate 203, and the middle part of the fixed plate 203 is embedded with a groove 204 , and the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com