Clamping device for hinged fixed circuit board production

A technology of clamping device and fixing device, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems of high cost of clamping device, clamping and trouble of circuit board clamping and fixing device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

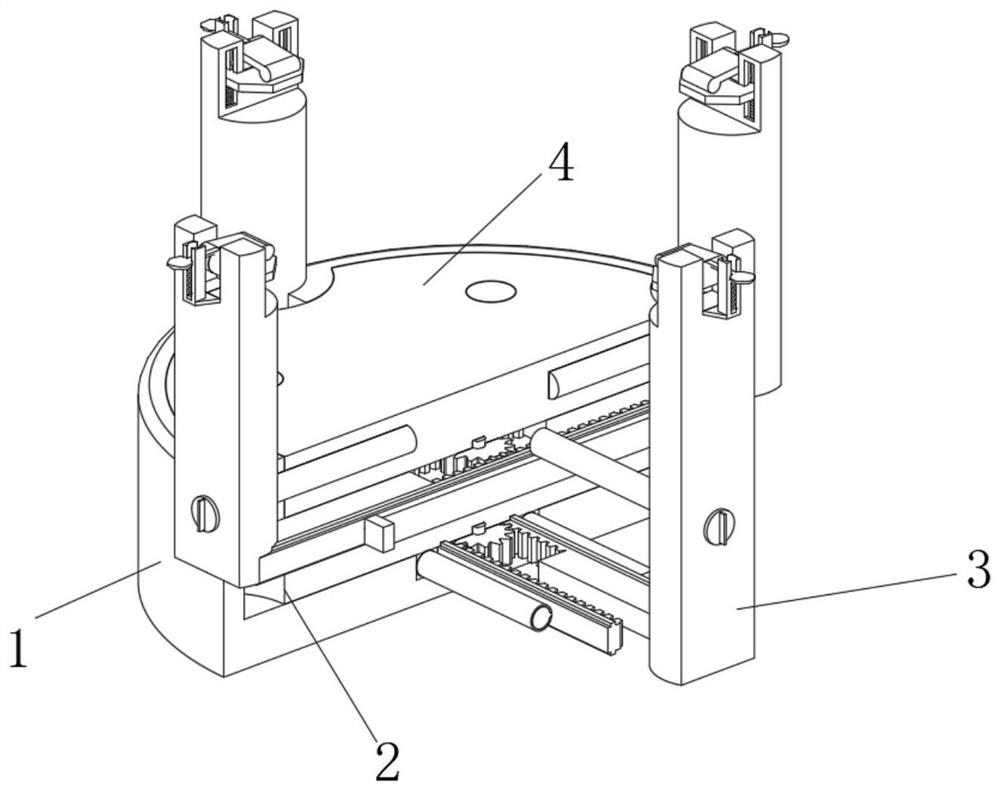

[0047] see Figure 1-Figure 10 As shown, a clamping device for the production of hinged fixed circuit boards is provided, including a protective seat 1, and a bottom receiving and pressing device 2 is provided inside the protective seat 1 near the bottom side, and the bottom of the protective seat 1 accepts pressing and covering The upper side of the device 2 is provided with an upper cover fixing device 4, and the center of the side wall of the protective seat 1 is symmetrical with two sets of clamping and positioning devices 3 arranged up and down. The two sets of clamping and positioning devices 3 are respectively arranged between the protective seat 1 and the Undertake between the crimping device 2 and the upper cover fixing device 4;

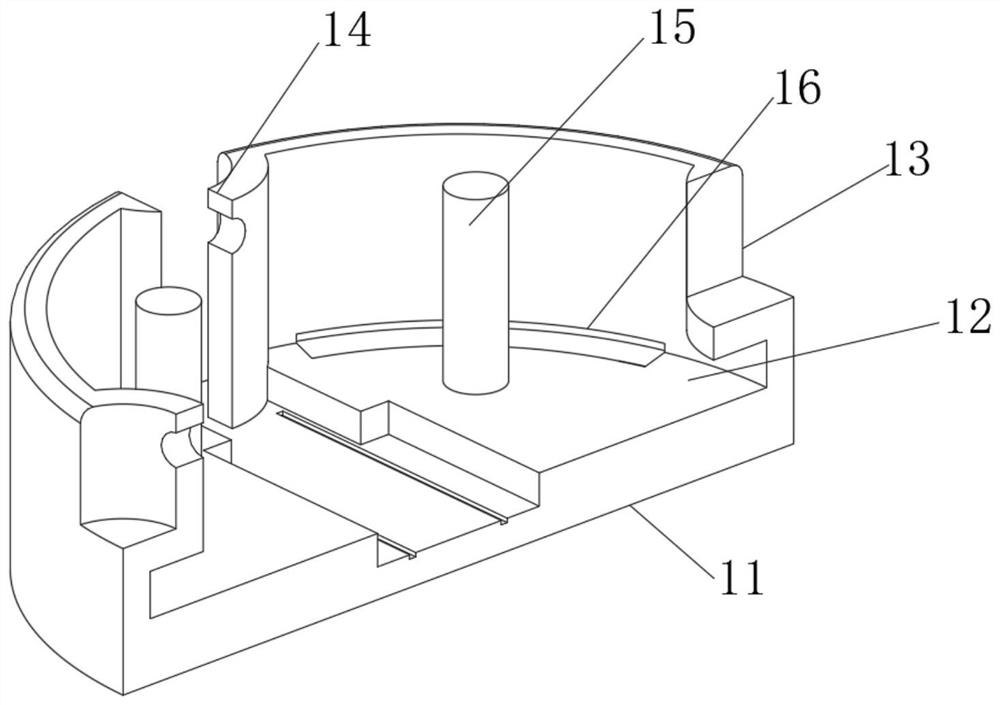

[0048] The protective seat 1 includes a protective shell 11, and the side wall of the protective shell 11 is provided with rod slots 13 in a circular arrangement. Through the placement chamber 12 at the top of the protective shell 11;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com