A kind of ceramic-based media stirring mill and grinding method thereof

A ceramic-based and medium-based technology, which is applied in the field of ceramic-based medium-stirred mills and their grinding, can solve problems such as unfavorable sorting operations, insufficient effective specific surface area, and easy deformation of steel balls, so as to facilitate the start-up of the mill and solve the problems. Difficulty in starting, effect of reducing media consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Design a 280kw ceramic base media stirring mill for grinding iron coarse concentrate.

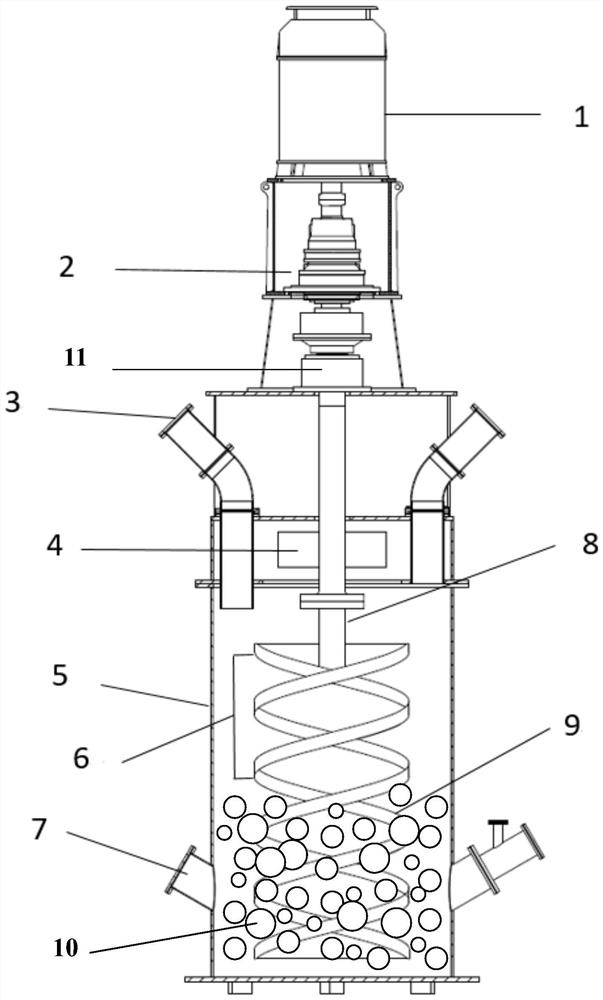

[0064] The ceramic-based media stirring mill, the structure diagram is shown in figure 1 , including a cylinder body 5, a stirring device and a ceramic base medium 10; the cylinder body 5 forms a grinding cavity, a grinding ore feeding port 7 is arranged below the cylinder body 5, a grinding overflow port 4 is arranged above the cylinder body 5, and the grinding cavity A stirring device is provided inside, and the stirring device includes a high-torque motor 1, a reducer 2, a screw agitator and a coupling 11; the screw agitator includes a screw stirring shaft 8 and a screw stirring blade 9 provided on the screw stirring shaft 8; high torque The motor 1 is connected with the reducer 2, the reducer 2 is connected with the screw shaft 8 of the screw agitator through the coupling 11, and the grinding cavity is filled with the ceramic base medium 10 through the grinding medium supplementa...

Embodiment 2

[0070] A kind of ceramic base medium stirring mill, its structure is the same as that of embodiment 1, and the difference is:

[0071] In this embodiment, the ceramic-based medium is a ceramic-metal composite ball, and by mass ratio, the ceramic content is 80%, and the metal content is 20%. The metal is preferably alloy steel.

[0072] For the ceramic-based medium added in this example, the percentage of the ceramic-based medium of each size in the total mass of balls used is:

[0073] The diameter of 20~25mm ceramic metal composite ball is 45%;

[0074] The diameter of 14~17mm ceramic metal composite ball is 35%;

[0075] The diameter is 8-10mm ceramic metal composite ball 20%.

[0076] A grinding method, using the ceramic-based media stirring mill of the present embodiment, includes the following steps:

[0077] (1) Configure the minerals to be ground into mineral pulp to be ground, pass the mineral pulp to be ground into the grinding chamber, and put the following three...

Embodiment 3

[0082] A kind of ceramic base medium stirring mill, its structure is the same as that of embodiment 1, and the difference is:

[0083] In this embodiment, the ceramic-based medium is a ceramic-metal composite ball, and by mass ratio, the ceramic content is 50%, and the metal content is 50%. The metal is preferably alloy steel.

[0084] For the ceramic-based medium added in this example, the percentage of the ceramic-based medium of each size in the total mass of balls used is:

[0085] The diameter of 20~25mm ceramic metal composite ball is 40%;

[0086] The diameter of 14~17mm ceramic metal composite ball is 40%;

[0087] The diameter is 8-10mm ceramic metal composite ball 20%.

[0088] A grinding method, using the ceramic-based media stirring mill of the present embodiment, includes the following steps:

[0089] (1) Configure the minerals to be ground into mineral pulp to be ground, pass the mineral pulp to be ground into the grinding chamber, and put the following three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com