Preparation method of light honeycomb molecular sieve purification module

A purification module and molecular sieve technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low adsorption capacity, high bulk density, high price, etc., to increase the specific surface area, reduce the overall density, and improve the effective The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

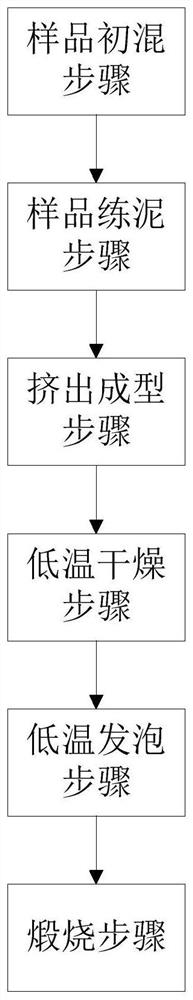

[0027] Please refer to figure 1 , The preparation method of the lightweight honeycomb molecular sieve purification module of the embodiment of the present invention includes a sample initial mixing step, a sample slime step, an extrusion molding step, a low-temperature drying step, a low-temperature foaming step, and a calcination step.

[0028] Sample initial mixing step: Weigh each raw material according to the following weight percentage: 60%-80% of molecular sieve powder, 25%-15% of binder, 10%-3% of surfactant, and 5%-2% of foaming agent; Put the weighed molecular sieve raw powder, binder, and foaming agent into a mixer for stirring and mixing until uniform, wherein the binder is clay. The present invention uses natural zeolite or artificially synthesized molecular sieve raw powder. Since the molecular sieve raw powder is in the form of powder, its direct application is greatly limited. Especially in the field of environmental protection, the filling resistance of powdery...

Embodiment 1

[0045](1) Sample initial mixing step: use 40kg of molecular sieve raw materials, 5.0kg of calcined kaolin powder of 1250 mesh, 0.5kg of sodium carboxymethyl cellulose, and 1.0kg of foaming agent into a mixer for stirring and mixing until uniform, time For 20 minutes, the temperature was controlled at 30°C.

[0046] (2) Sample mud refining step: add 30.0kg water and 0.6kg glycerin and polyethylene glycol, 0.2kg silica sol solution to the above (1), the rate of adding solution is 5 kg / min, continue to stir and knead The temperature is controlled at 35°C, and the stirring speed is 50r / min. Put the muddy billet after mixing evenly into the mud mixer for repeated mixing and extrusion, and the temperature of the mud is controlled Rough refining is repeated 5 times, vacuuming, and the vacuum degree is

[0047] (3) Extrusion molding step: Put the refined mud into a low-pressure vacuum extruder for molding and extrusion. During extrusion, the temperature is controlled at 30°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com