Electrode plate, electrode assembly, electrochemical device, electronic device and preparation method

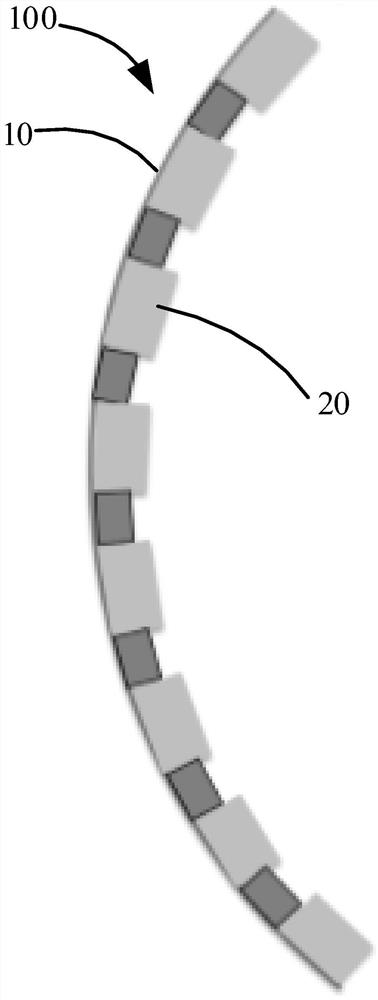

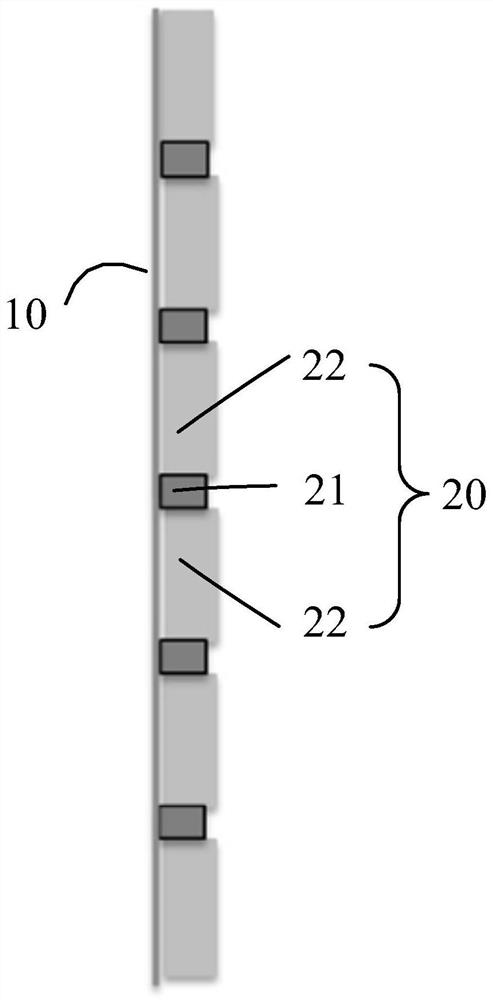

An electrode pole piece and electrode assembly technology, which is applied in the fields of electronic devices and their preparation, electrochemical devices, electrode pole pieces, and electrode assemblies, can solve problems such as hidden dangers, pole piece powder dropping, and safety problems, and achieve the effect of improving powder dropping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1) Preparation of negative pole piece:

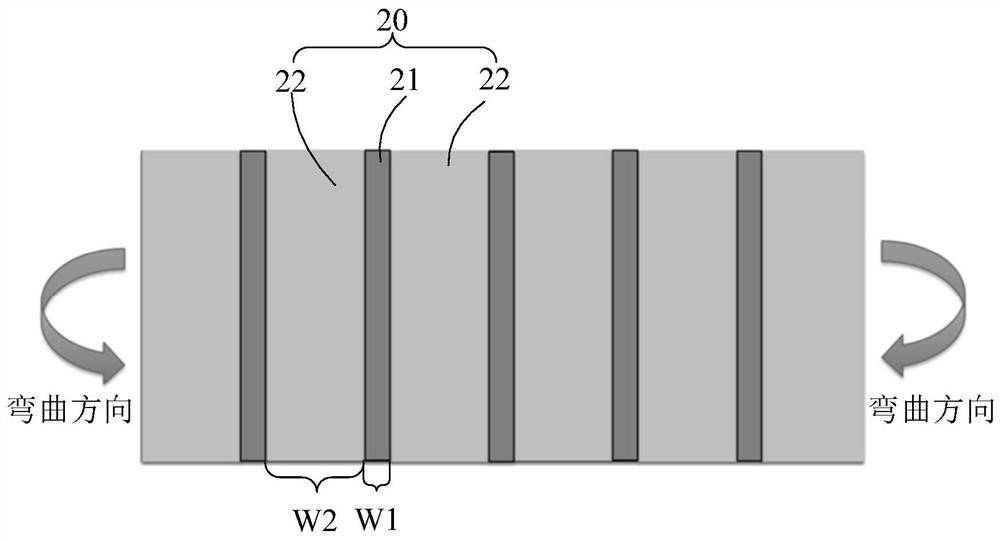

[0064] Graphite is used as the negative electrode active material, conductive carbon black is used as the conductive agent, and styrene-butadiene rubber (SBR) is used as the binder, and the above materials are mixed according to graphite: conductive carbon black: styrene-butadiene rubber = 96: 1.5: 2.5, Deionized water was added as a solvent to prepare a negative electrode slurry with a solid content of 50%, and stirred evenly. The negative electrode slurry was uniformly coated on the first surface of the 6 μm negative electrode current collector copper foil, dried and cold pressed at 110° C. to obtain a negative electrode sheet with a thickness of 200 μm in the second region. Adopt the method of twice intermittent cold pressing to cold press along the coating direction to form 10 first areas, and the area without cold pressing is the second area, wherein the compacted density P1 of the first area is the same as that of the secon...

Embodiment 2

[0072] The difference between this example and Example 1 is that in the preparation of the negative electrode sheet, the ratio P1 / P2 of the compacted density P1 of the diaphragm in the first region to the compacted density P2 of the diaphragm in the second region is 1.5, and the corresponding The thickness ratio H1 / H2 of the first region and the second region is 0.6, the bonding force V1 / V2 of the first region and the second region is 1.8, and the rest are the same as in the first embodiment.

Embodiment 3

[0074] The difference between this example and Example 1 is that in the preparation of the negative electrode sheet, the ratio P1 / P2 of the compacted density P1 in the first region to the compacted density P2 of the diaphragm in the second region is 1.3, and the corresponding first The thickness ratio H1 / H2 of the region and the second region is 0.75, the bonding force V1 / V2 of the first region and the second region is 1.34, and the rest are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com