Method for in-situ micro-area quantitative analysis of beryllium content

A quantitative analysis, micro-area technology, applied in the analysis of materials, material analysis using wave/particle radiation, measurement devices, etc. Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

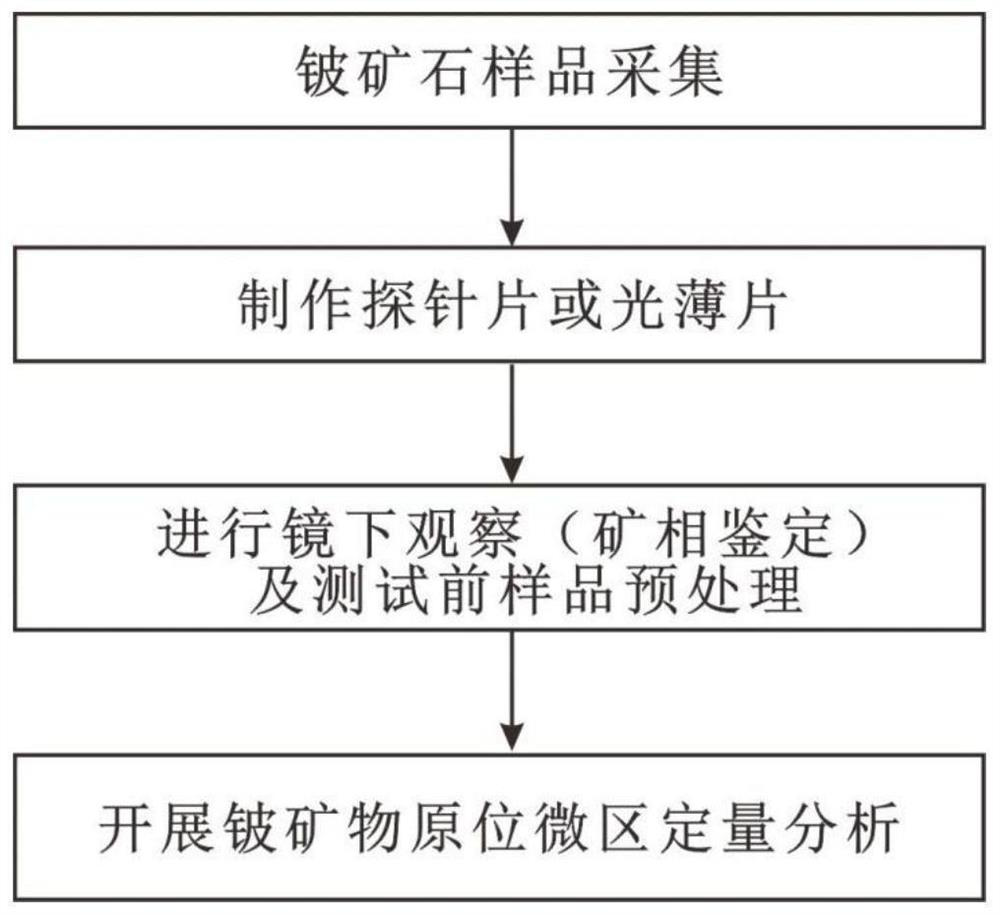

[0027] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

[0028] Step 1, collecting beryllium ore samples;

[0029] Collect beryllium ore samples through field geological surveys or surveys. The sample size is 2cm×5cm×8cm or 3cm×6cm×9cm; the number of samples is 1 to 3 pieces; because of the in-situ micro-area quantitative analysis, usually one beryllium mineral (that is, one sample) can meet the testing requirements. In order to prevent the impact of unforeseen factors (such as sample damage during sample preparation, diversity of beryllium mineral types, and statistical needs, etc.), it is recommended to collect two more samples.

[0030] Step 2, making a probe sheet or light sheet;

[0031] Mechanically grind and polish the beryllium ore sample collected in step 1 to make a probe sheet or light sheet. The size of the probe sheet is 2cm×2cm×1cm; the size of the light sheet is 2cm×3cm×0.3mm.

[0032] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com