Liquid fly ash material for road abutment back backfilling and preparation process of liquid fly ash material

A preparation process, fly ash technology, applied in the field of building materials, can solve the problems of long-time preparation, low preparation efficiency, and inability to meet the backfilling of road abutments, so as to improve the preparation speed, avoid full filling, and reduce stirring and mixing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a liquid fly ash material used for backfilling of highway abutments and a preparation process thereof. The composition material of the liquid fly ash material includes cement, fly ash, water and admixture, and its mixing ratio is cement:powder Coal ash: water: additive = 10-20: 80-90: 30-40: 0.1-0.2, wherein the content of the additive is 1% of the cement content.

[0040] The liquid fly ash material used for backfilling of road abutments has the characteristics of high strength, light weight, high compactness, low compressibility, high rigidity and the like. Liquid fly ash is a lightweight material, and the additional load on the foundation after backfilling is small, which greatly reduces the additional stress on the soil at the bottom of the abutment back foundation. Liquid fly ash has good fluidity before initial setting, and the backfill is self-compacting, which can avoid the defect of incomplete filling of conventional backfill materials. ...

Embodiment 2

[0045] Such as Figure 4 As shown, the present invention provides a kind of preparation technology of the liquid fly ash material that is used for road abutment backfill, and this preparation technology comprises the following steps:

[0046] S100, weighing cement, water, fly ash and admixture according to the proportion;

[0047] S200, sending cement, fly ash, water and additives into the material mixing equipment, and mixing by the material mixing equipment at normal temperature to obtain the fly ash-water-cement mixture, which is taken out;

[0048] S300. Send the fly ash-water-cement mixture prepared in step S200 into a stirring device, and stir at normal temperature to prepare a liquid fly ash material.

[0049] Further, in step S100, the water is divided into two parts, and the ratio of the two parts of water is 10-20:80-90, wherein the water with a mass fraction of 10-20 is mixed with cement, and the mass fraction is 80- 90% water mixed with fly ash;

[0050] At the ...

Embodiment 3

[0073] Such as Figure 4 Shown, the present invention provides another kind of preparation technology for the liquid fly ash material of backfilling of highway abutment, and this preparation technology comprises the steps:

[0074] S100, weighing cement, water, fly ash and admixture according to the proportion;

[0075] S200, sending cement, fly ash, water and additives into the material mixing equipment, and mixing by the material mixing equipment at normal temperature to obtain the fly ash-water-cement mixture, which is taken out;

[0076] S300. Send the fly ash-water-cement mixture prepared in step S200 into a stirring device, and stir at normal temperature to prepare a liquid fly ash material.

[0077] In step S400, the stirring time is 2 minutes.

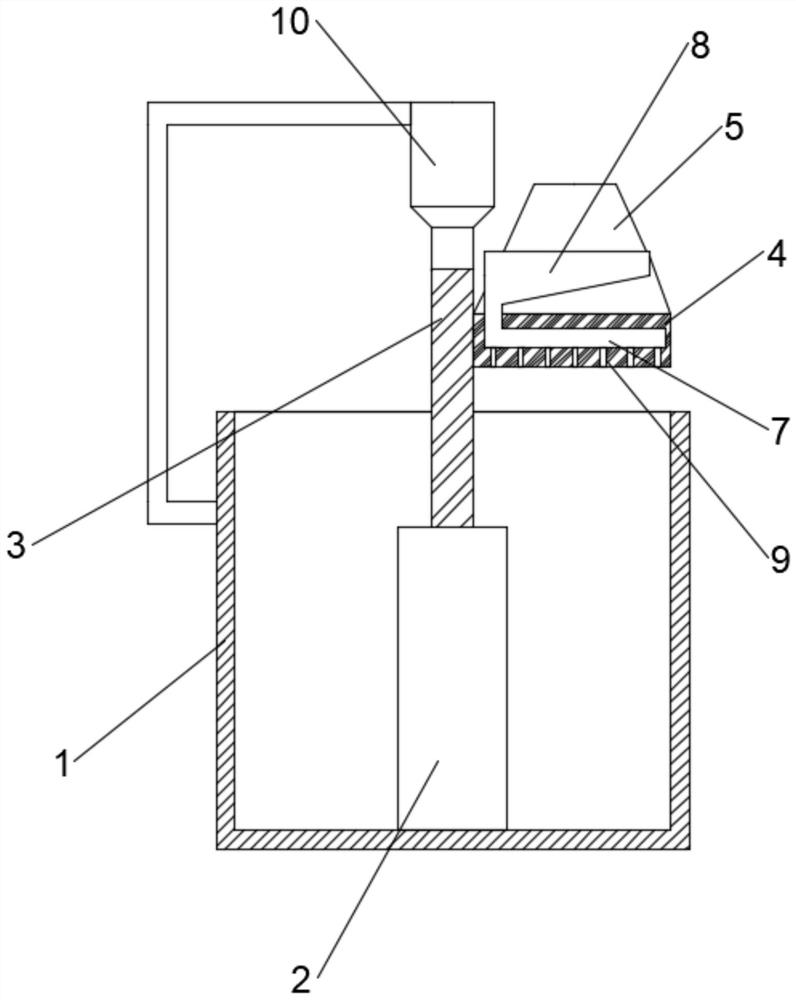

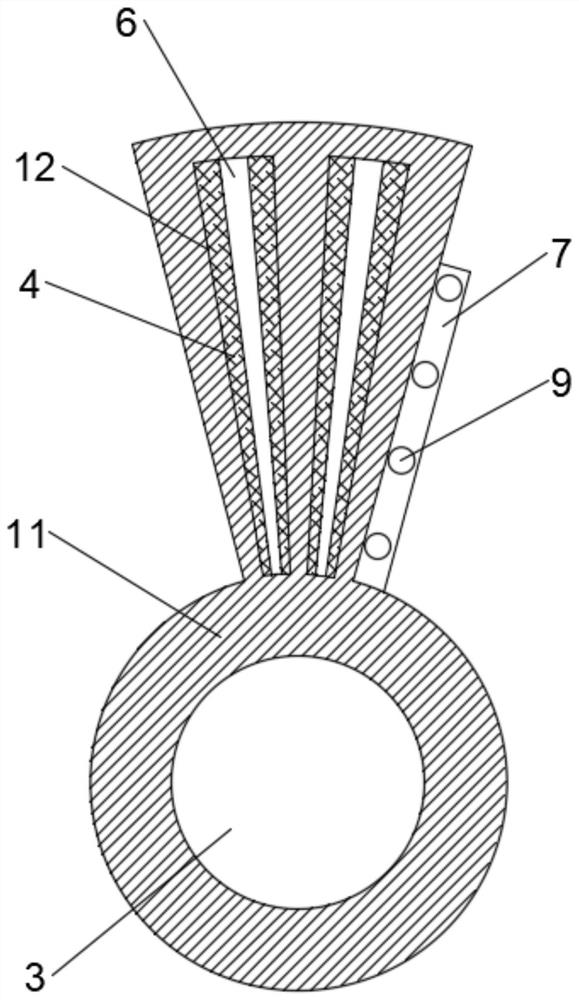

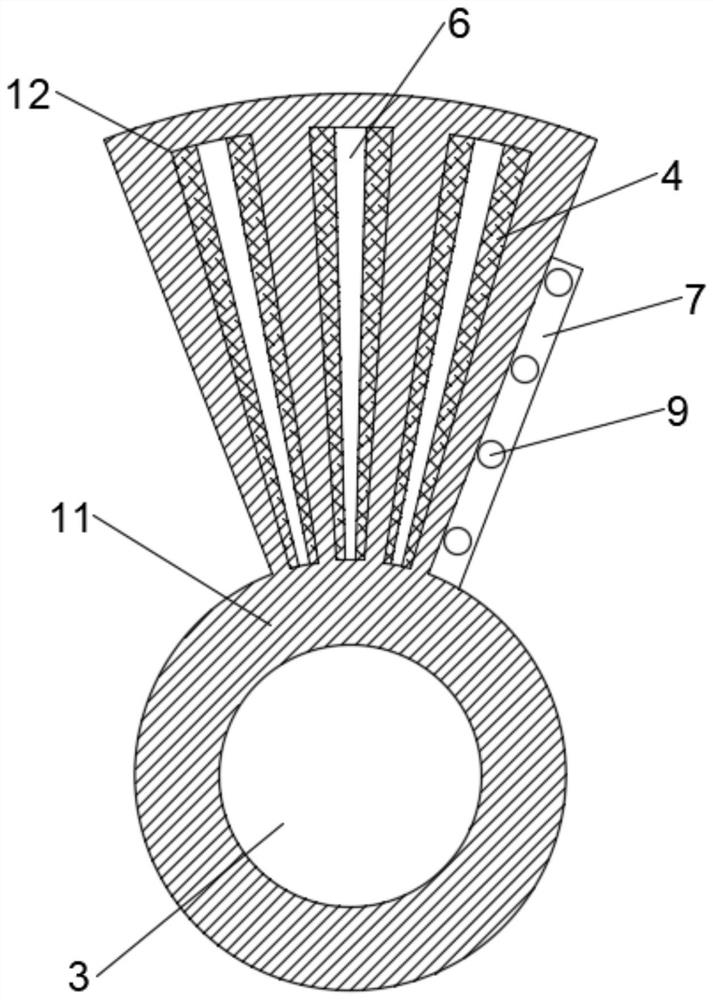

[0078] Such as figure 1 with image 3As shown, based on the above-mentioned preparation process, this embodiment also proposes a material mixing device for the preparation process of liquid fly ash material, the material mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com