Cigarette filter stick cutter box, system and method

A cutting knife and knife box technology, which is applied in the field of new heat-not-burn cigarette equipment, can solve problems such as difficult cleaning, affecting filter rods, paper tubes, firmware segmentation processing accuracy, guide mechanism and cutter knife box installation position errors, etc. To achieve the effect of improving the processing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

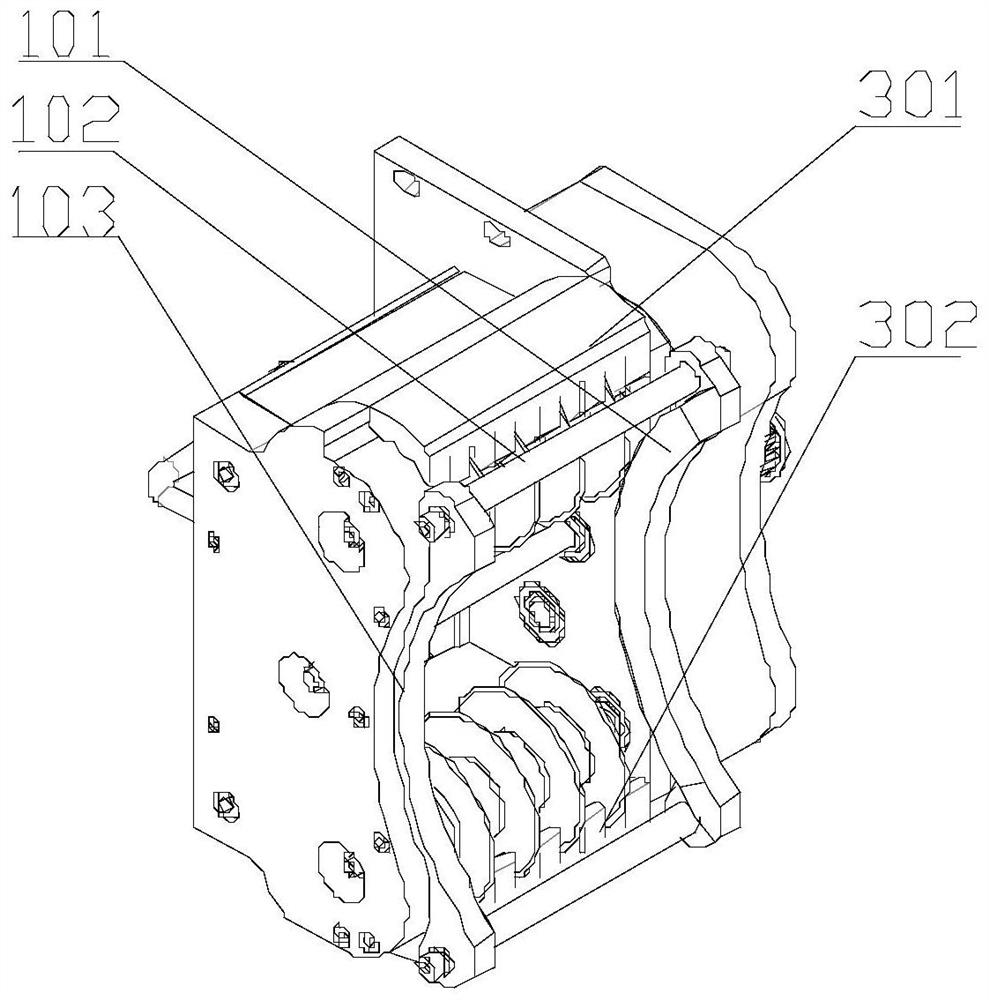

[0024] like figure 1 As shown, a knife box for cutting a cigarette filter rod includes a knife box body, a sharpening mechanism and a knife assembly connected with the knife box; the knife assembly includes several blades, and the knife sharpening mechanism is provided with blades one by one Corresponding to the sharpening groove, when the blade is in the working state, the movement trajectory of the blade passes through the sharpening groove, and the side of the blade has a set gap from the grinding surface of the sharpening groove; the waste debris attached to the blade is removed after passing through the sharpening groove.

[0025] Further, the knife box body is also connected with a guide mechanism, the guide mechanism includes an arc-shaped guide, and a certain area of the side of the arc-shaped guide has a set inclination angle; the arc-shaped guide includes a first guide plate and The second guide plate; the first guide plate is connected with the second guide plate ...

Embodiment 2

[0035] A cigarette system, using the cigarette filter rod cutter box as described in the above embodiments to cut filter rods, paper tubes or fasteners.

Embodiment 3

[0037] A method for using a cigarette filter stick cutter box, comprising:

[0038] The filter rod, paper tube and fastener bar are guided into the cutter assembly in the knife box for cutting;

[0039] During the cutting process, the sticky waste sticks to the edge of the cutter. When the cutter rotates at high speed, it will pass through the sharpening groove of the sharpening mechanism to grind off the waste sticking to the blade;

[0040] Further, the dust is blown and cleaned by the compressed air located at the upper rear of the cutter box, and the bottom is sucked into the dust removal hopper through the dust removal port.

[0041]Specifically, the rods such as filter rods, paper tubes, and firmware, which are located in the groove of the rotating sheave and are transferred into the knife box with the rotation of the sheave, are introduced into the knife box through the guide mechanism integrated on the knife box body for cutting and classification. part. The cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com