Impurity removing device for nut machining

A nut and consistent technology, applied in the field of impurity removal devices for nut processing, can solve the problems of loose fastener connections, clean metal debris, and looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

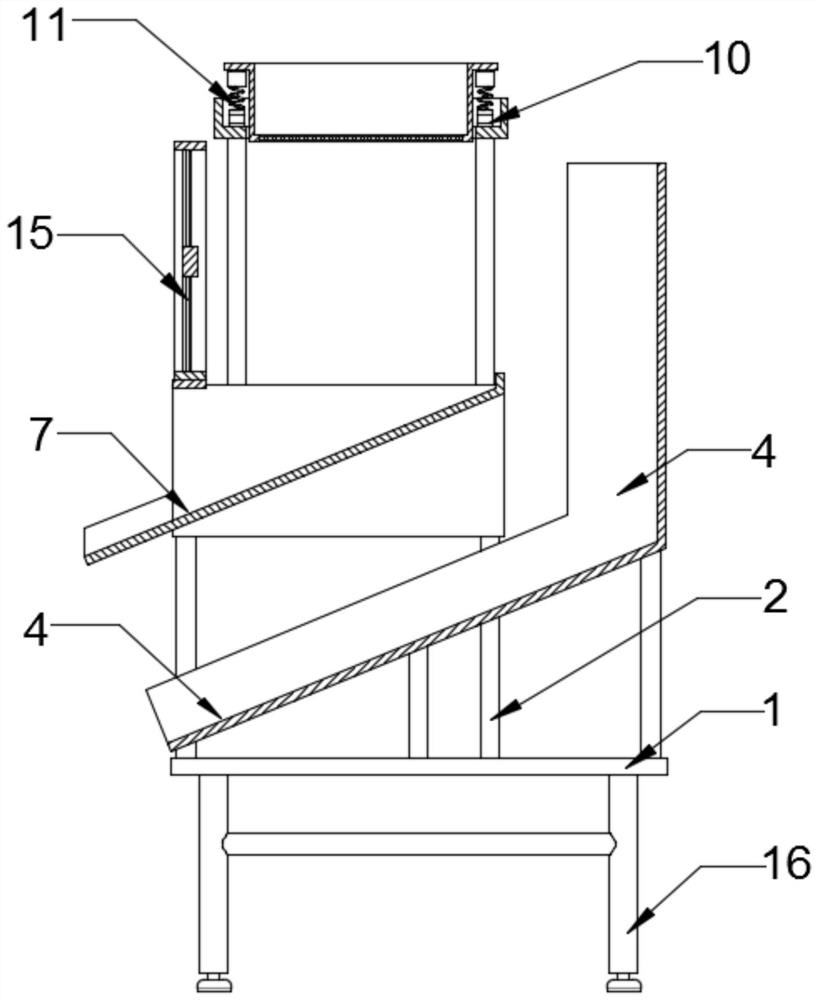

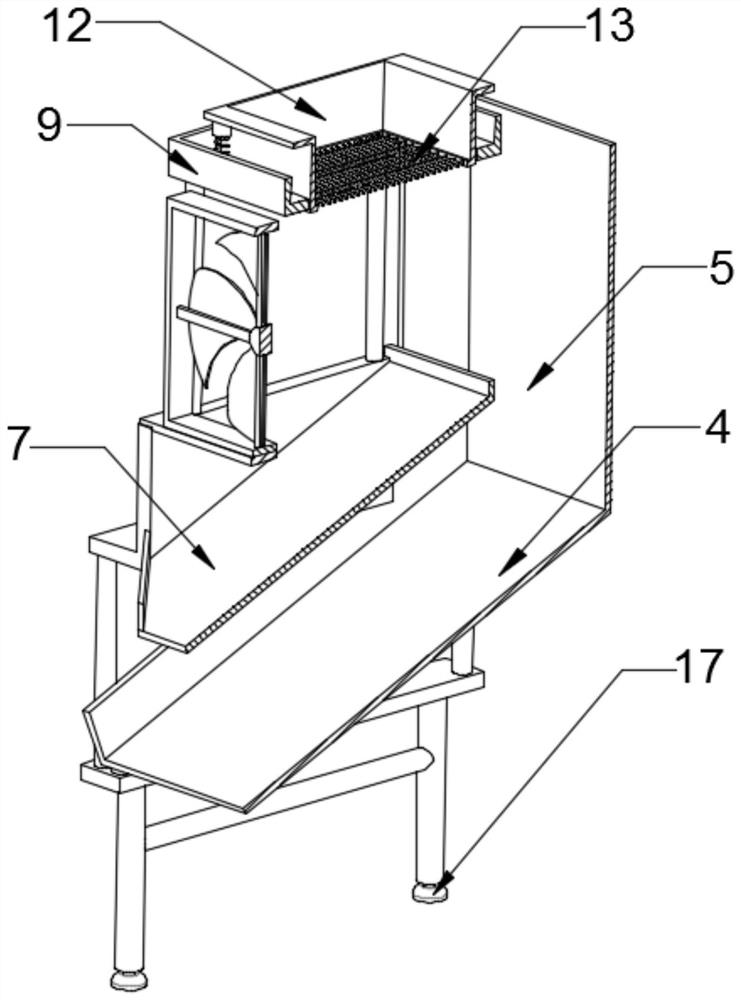

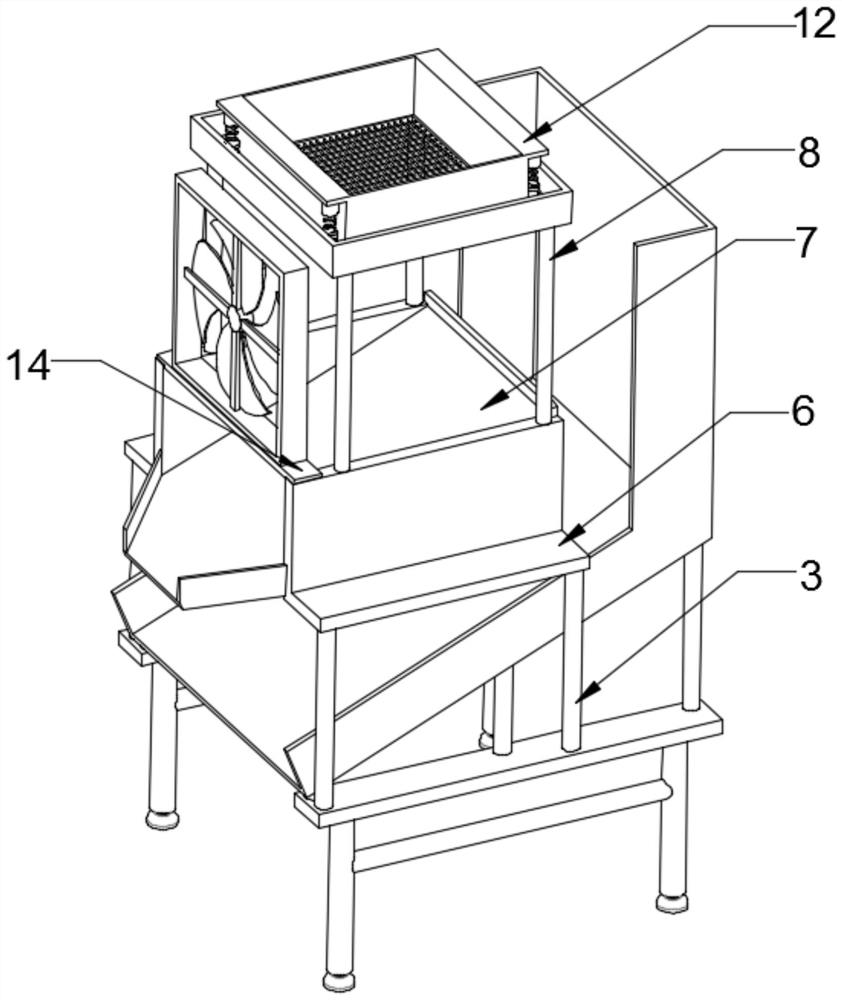

[0025] A kind of nut processing of the present embodiment uses impurity removing device, refer to Figure 1-3 : It includes a front and rear symmetrical support horizontal plate 1, and front and rear symmetrical first struts 2 and second struts 3 are fixed on the top surface of the support horizontal plate 1, and the first strut 2 is located on the inner side of the second strut 3 The top of the first pole 2 is connected with a waste sloping plate 4, and the right end of the waste swash plate 4 is connected with a baffle plate 5 with the same front and rear width, and the top support of the second pole 3 is connected with a front and rear symmetrical L-shaped connection. The plate 6 and the connecting plate 6 are connected with a material guide inclined plate 7, and the top surface of the connecting plate 6 is fixed with a front and rear symmetrical third strut 8; the top of the third strut 8 is fixed with a frame 9 for removing impurities, Electromagnetic vibrators 10 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com