Continuous through dry sand mill for ferrite

A technology of ferrite and sand mill, which is applied in the direction of grain processing, etc. It can solve the problems of mixing uniformity, poor consistency, affecting the performance of permanent magnet ferrite, and high water content of slurry, so as to achieve good uniformity and overcome Incomplete response, high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] In order to overcome the shortcomings of the dry process manufacturing method, the present invention provides a continuous passing dry sand mill for ferrite, an improved device that takes the manufacture of sintered strontium ferrite permanent magnet materials as an example.

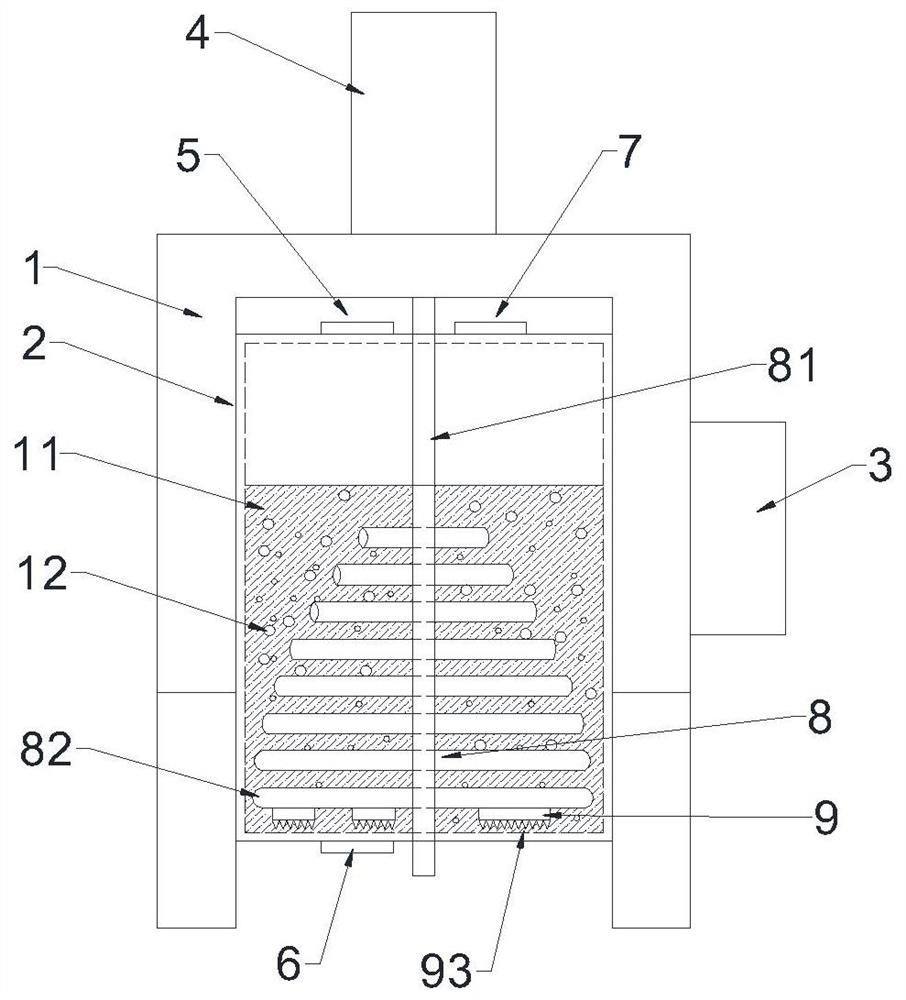

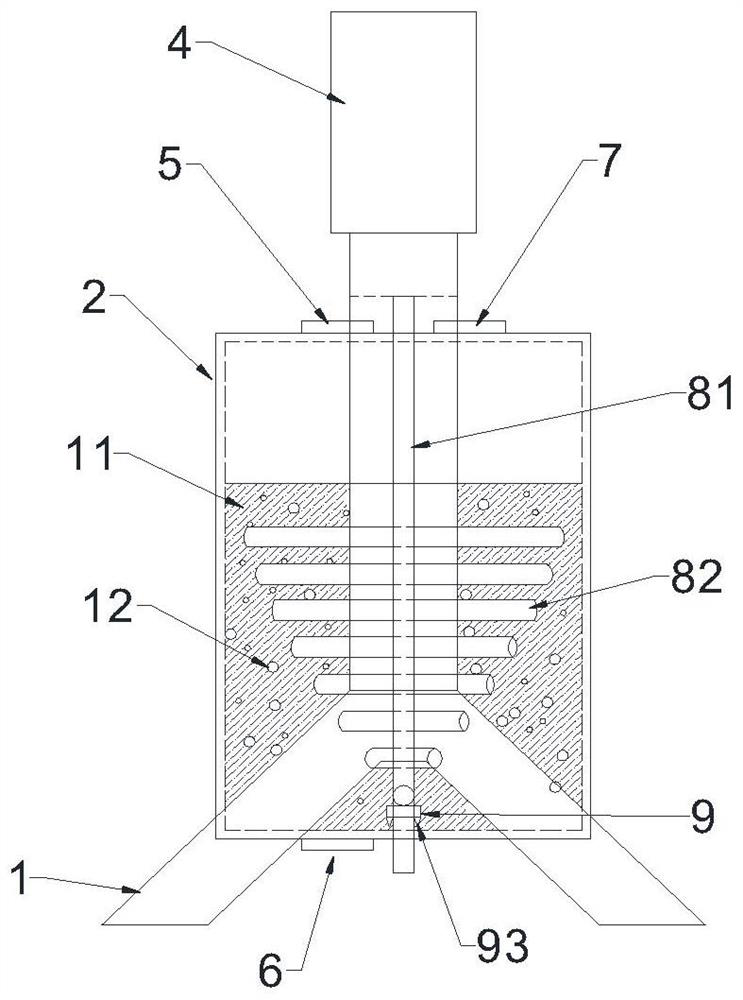

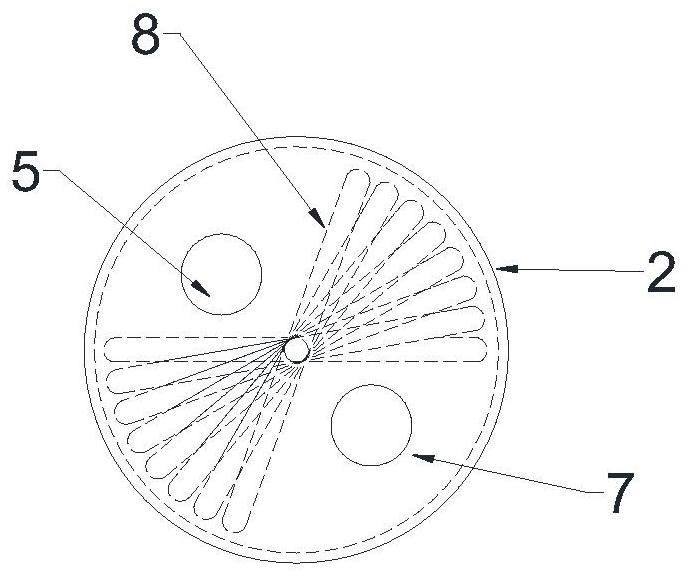

[0023] Figure 1 to Figure 7 A continuous pass dry sand mill for ferrite according to an embodiment of the present invention is schematically shown. as the picture shows,

[0024] According to one aspect of the present invention, a continuous passing dry sand mill for ferrite is provided, including a support 1, a material barrel 2, an electric control cabinet 3, a motor 4, a material inlet 5, and a material outlet 6. The exhaust port and the stirring part 8, the material barrel 2 is in the shape of a cylinder, the material barrel 2, the electric control cabinet 3 and the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com