Efficient dustproof sealing structure of low-voltage inverter

A dust-proof sealing, inverter technology, applied in the structural parts of the conversion equipment, the parts of the connecting device, the structural parts of the electrical equipment, etc. Offset and other problems, to achieve the effect of increasing the sealing and dustproof effect and the effect of rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

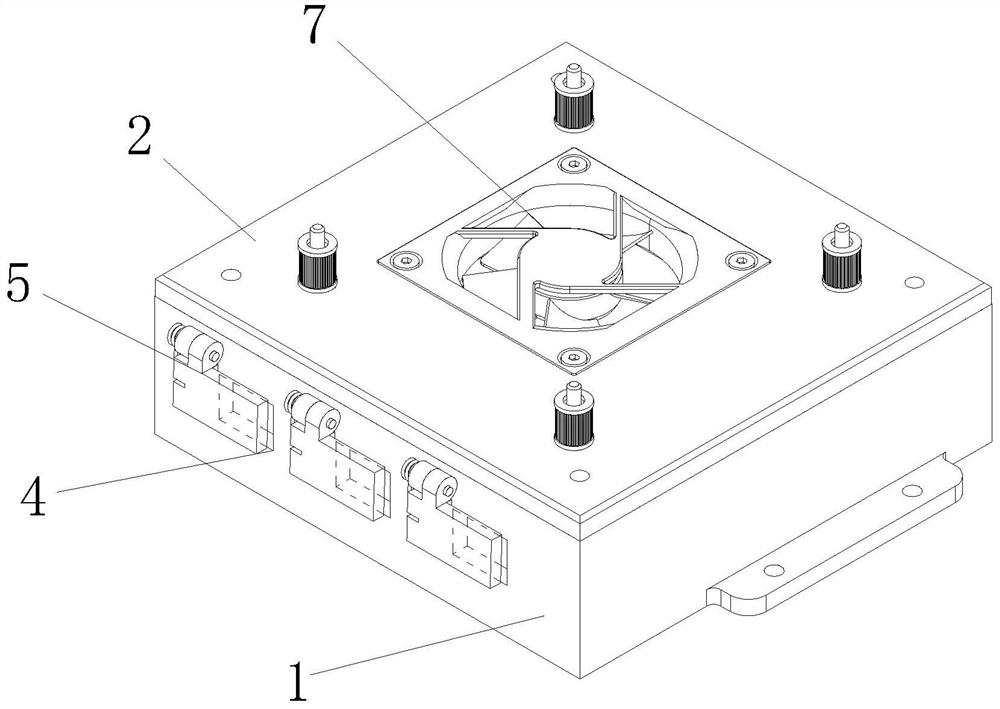

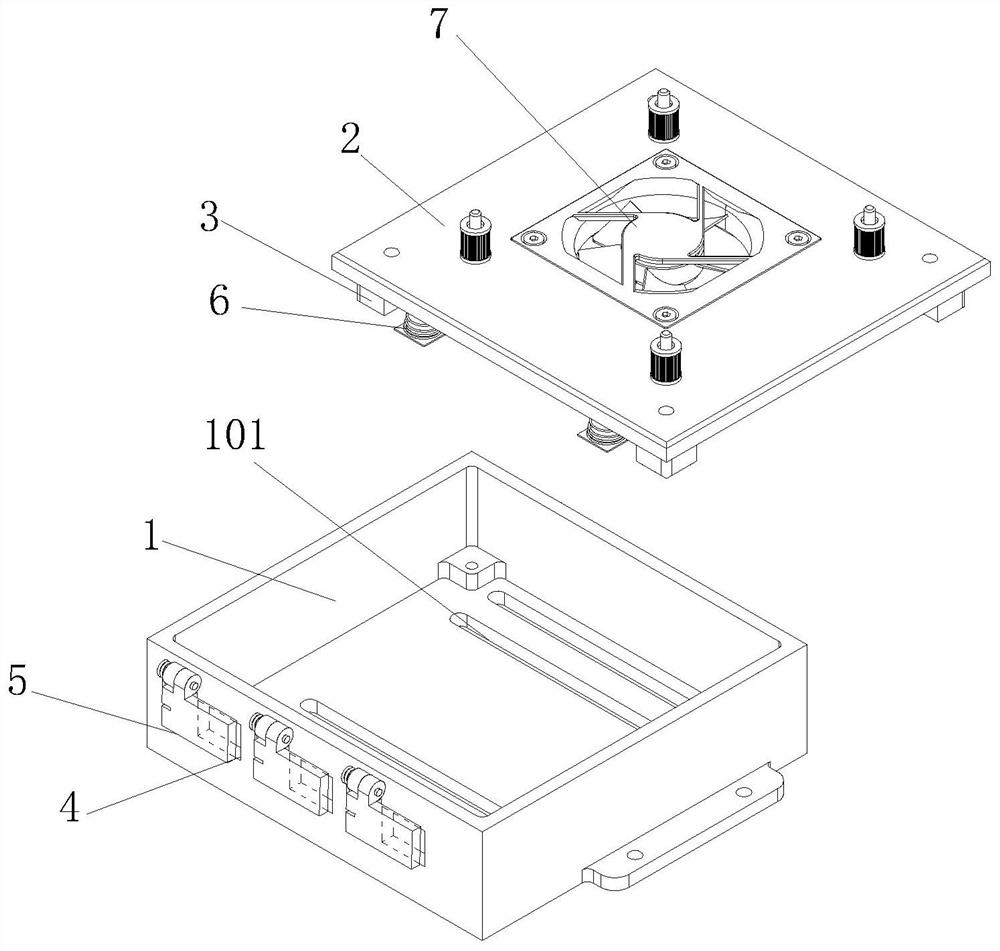

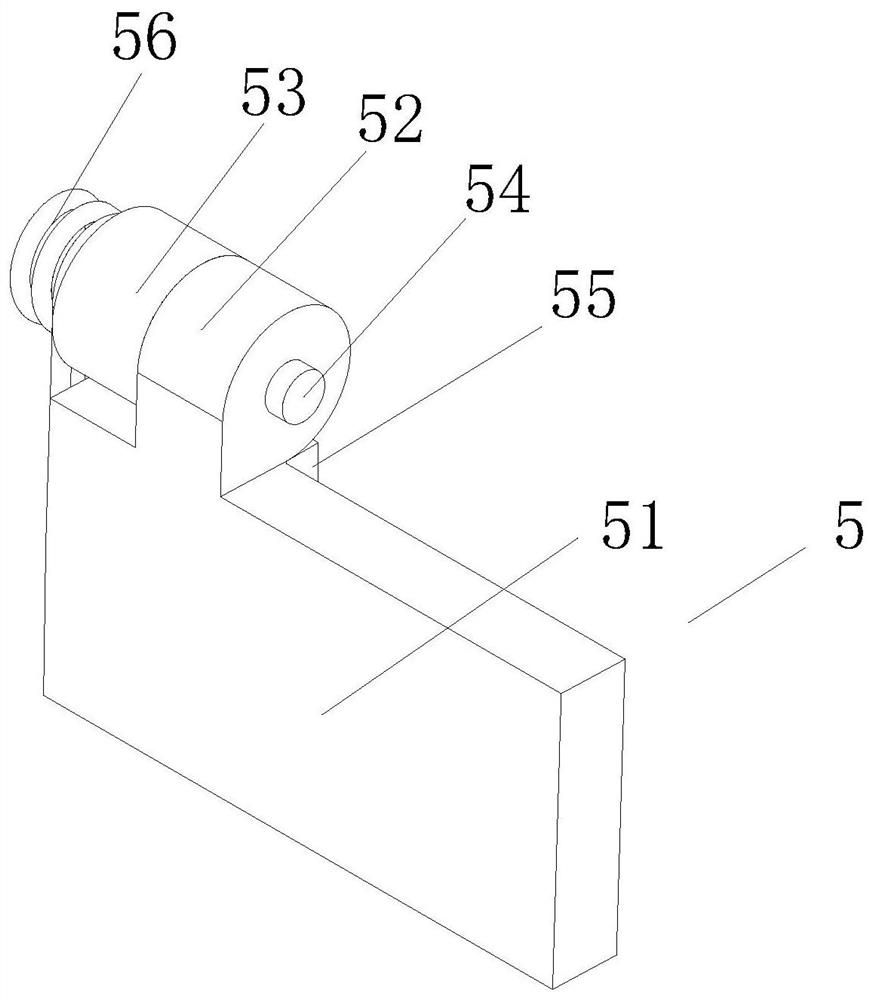

[0034] see Figure 1-2 As shown, the present invention provides a high-efficiency dust-proof sealing structure of a low-voltage inverter through improvement, including a bottom case 1, a top cover 2, a connection fixing block 3, a cable opening 4, an automatic closing structure 5, a pressure Tight positioning structure 6 and auxiliary heat dissipation device 7, top cover 2 is provided on the upper end of bottom case 1, after putting the low-voltage inverter into bottom case 1, it is covered by the upper end of top cover 2, and connected by connecting fixed block 3 , to prevent the low-voltage inverter from falling out, the front end of the bottom shell 1 is provided with a plurality of cable openings 4, and the set cable passages 4 are used to pass through the cables to connect with the low-voltage inverter, and the front end of the cable opening 4 An automatic closing structure 5 is provided to close the cable opening 4 to prevent dust from entering. The bottom of the top cov...

Embodiment 2

[0041] The present invention provides a high-efficiency dust-proof sealing structure of a low-voltage inverter through improvement. The size of the cable opening can be set according to the actual size of the cable, so that the cable passes through the cable When opening, the gap will not be too large, and the effect of sealing and dustproof is improved. A dustproof filter is installed on the outer side of the cooling fan 71 to prevent the cooling fan 71 from bringing dust into the bottom housing 1. Connect the slider 666 and The sliding connection in the chute 664 makes the connecting slider 666 better connect the top plate 61 and the sliding inner block 665, the bottom of the connecting spring 742 is fixed with the upper end of the heat conducting fin 741, and the top of the connecting spring 742 is fixed with the bottom of the fixed bracket 72, The heat conduction fins 741 are connected by the connection spring 742 so that they will not break away from the bottom of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com