A multi-domain semi-supervised fault diagnosis method and device for axial piston pump bearings

An axial piston pump and fault diagnosis technology, which is applied in measurement devices, neural learning methods, testing of mechanical components, etc., can solve problems such as cross-domain fault diagnosis of axial piston pump bearings, and achieve outstanding and powerful results. Effects of Domain Fault Diagnosis Advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

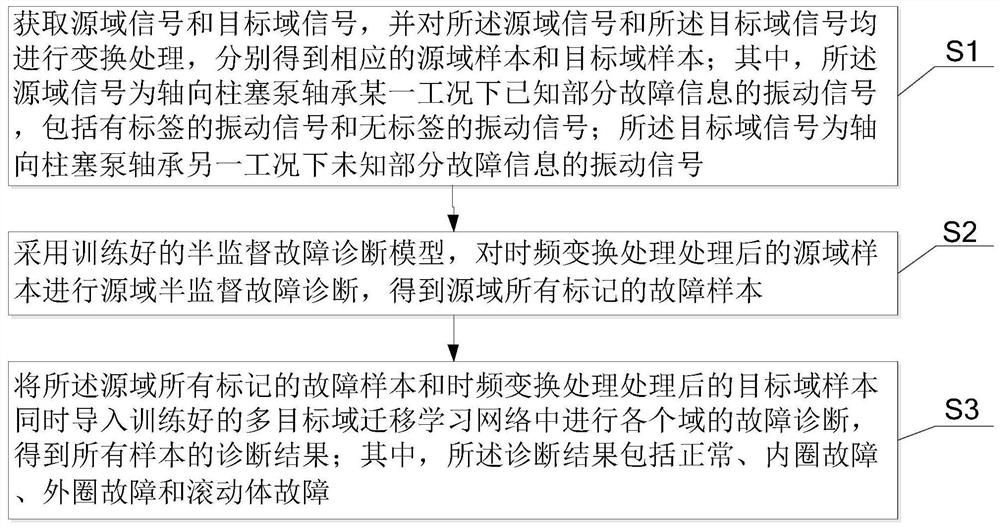

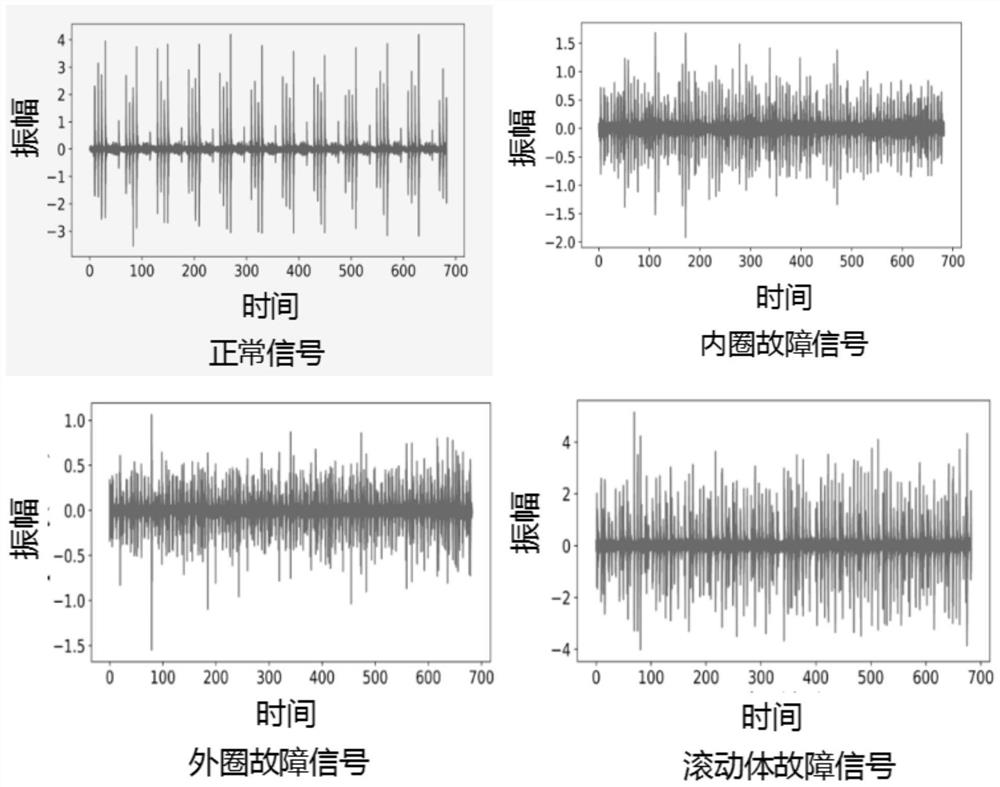

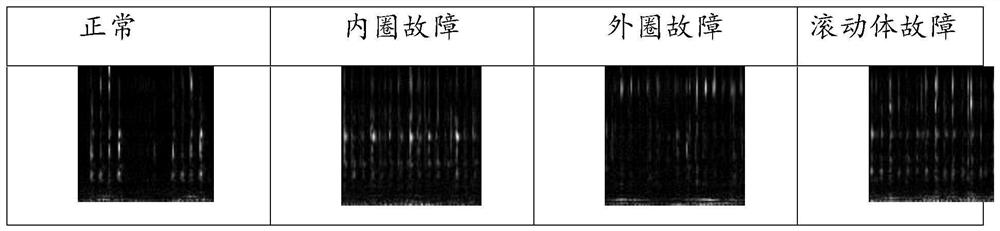

[0056] It should be noted that the labels include, but are not limited to, normal, inner ring failure, outer ring failure, and rolling element failure. like

[0065]

[0068]

[0071] L

[0078] 5) Repeat 3) and 4) until the position of the cluster center no longer changes.

[0082] Secondly, with the trained transfer learning network, the classifier will output the correct class labels for each domain sample. for

[0084]

[0086] The unlabeled samples of each target domain are introduced into the domain adaptation network together with the labeled source domain data, and the

[0087]

[0091] To verify the effectiveness of the method proposed in this patent, four classic transfer learning algorithms are used for comparison. respectively

[0093]

[0103] Those of ordinary skill in the art can understand that all or part of the steps in the method of the above-mentioned embodiments can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com