Exhaust valve structure of low-speed two-stroke marine diesel engine

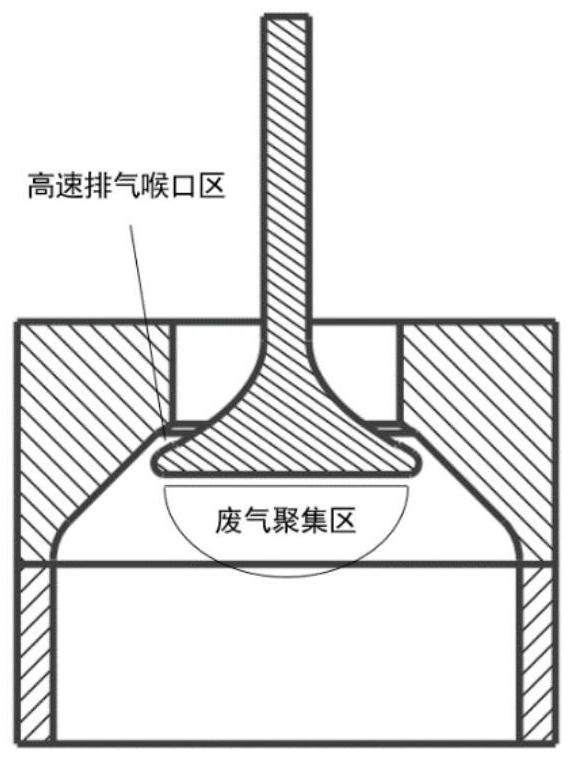

A marine diesel engine and exhaust valve technology, which is applied to mechanical equipment, combustion engines, engine components, etc., can solve the problems of exhaust gas accumulation and inability to discharge, and achieve the effects of low exhaust gas flow resistance, easy processing, and improved scavenging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

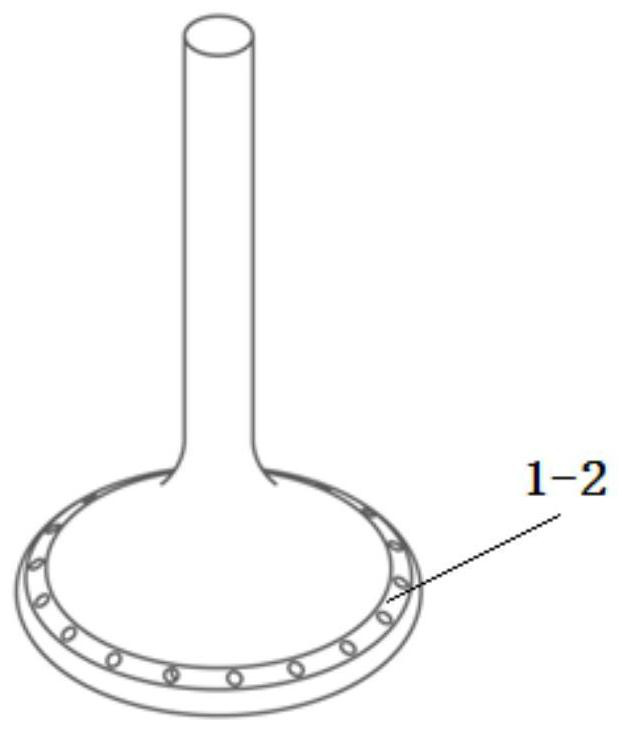

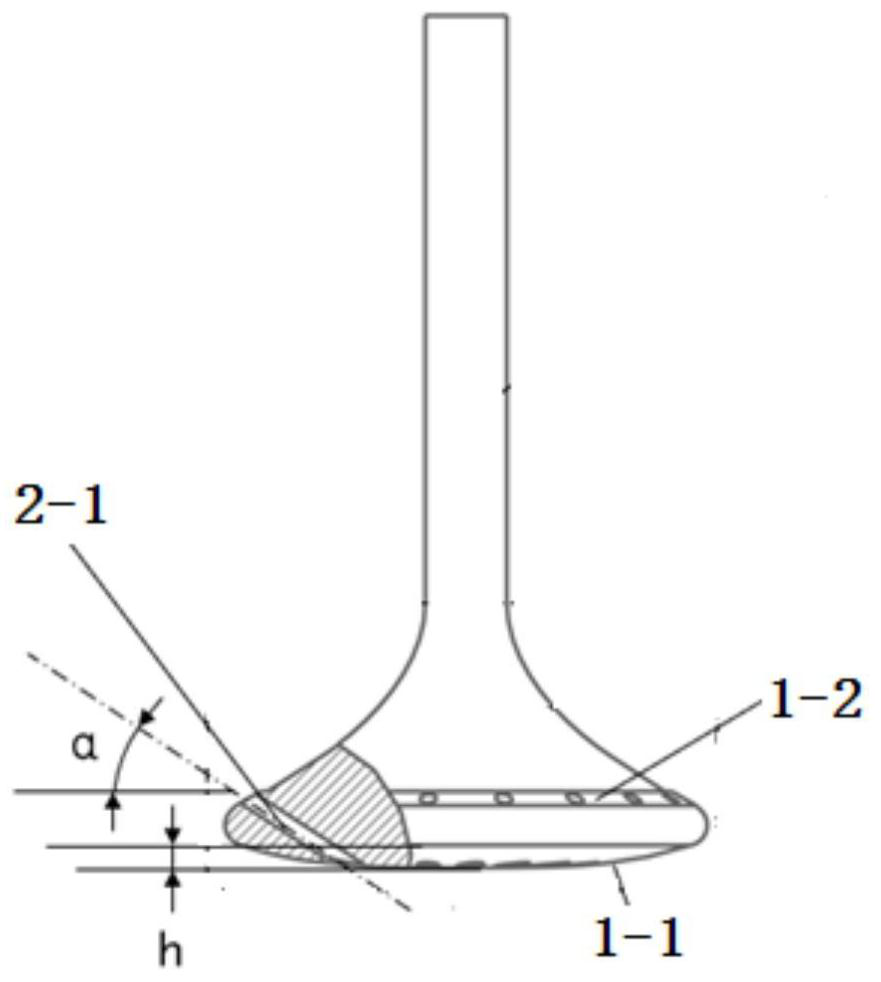

[0025] The exhaust gas runners are evenly arranged in a single ring around the center line of the exhaust valve, and the height h of the arc surface of the exhaust valve bottom surface from the horizontal line is 15mm (eg image 3 , Figure 4 ); the number of exhaust runners is 18. The angle α between the axis of the exhaust gas flow channel and the horizontal plane is 40°. The angle β between the centerline of the exhaust gas runner and the centerline of the valve projected to the horizontal plane is 15° (such as Figure 4 ); the section of the exhaust gas flow channel is circular and the diameter is 10mm. The chamfer of the exhaust gas runner intake port at the bottom surface of the valve is 2mm×2mm.

[0026] The experimental results show that the exhaust gas in the exhaust gas accumulation area under the exhaust valve is reduced by about 50% from the opening to the closing of the exhaust valve of the present invention, and the scavenging efficiency is improved by about 2...

Embodiment 2

[0028] The exhaust gas runner is evenly arranged around the center line of the exhaust valve with double rings in the circumferential direction, and the height h of the arc surface of the exhaust valve bottom surface from the horizontal line is 15mm (such as Figure 5 , Image 6 ); the number of exhaust gas flow channels is 18, of which the number of exhaust gas flow channels in the inner and outer rings is 9. The angle α between the axis of the exhaust gas flow channel of the inner ring and the horizontal plane is 30°; the angle α' between the axis of the exhaust gas flow channel of the outer ring and the horizontal plane is 40°. The angle β between the centerline of the exhaust gas runner and the centerline of the valve projected to the horizontal plane is 15° (such as Figure 4 ); the section of the exhaust gas flow channel is circular and the diameter is 10mm. The chamfer of the exhaust gas runner intake port at the bottom surface of the valve is 2mm×2mm.

[0029] The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com