High-temperature-resistant and yellowing-resistant liquid optical adhesive

A technology of yellowing resistance and high temperature resistance, used in adhesives, liquid degassing, chemical instruments and methods, etc., can solve the problems of poor temperature resistance and yellowing resistance, unable to meet long-term bonding and lamination, etc. Achieve uniform heating, excellent defoaming effect, and improve the effect of yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

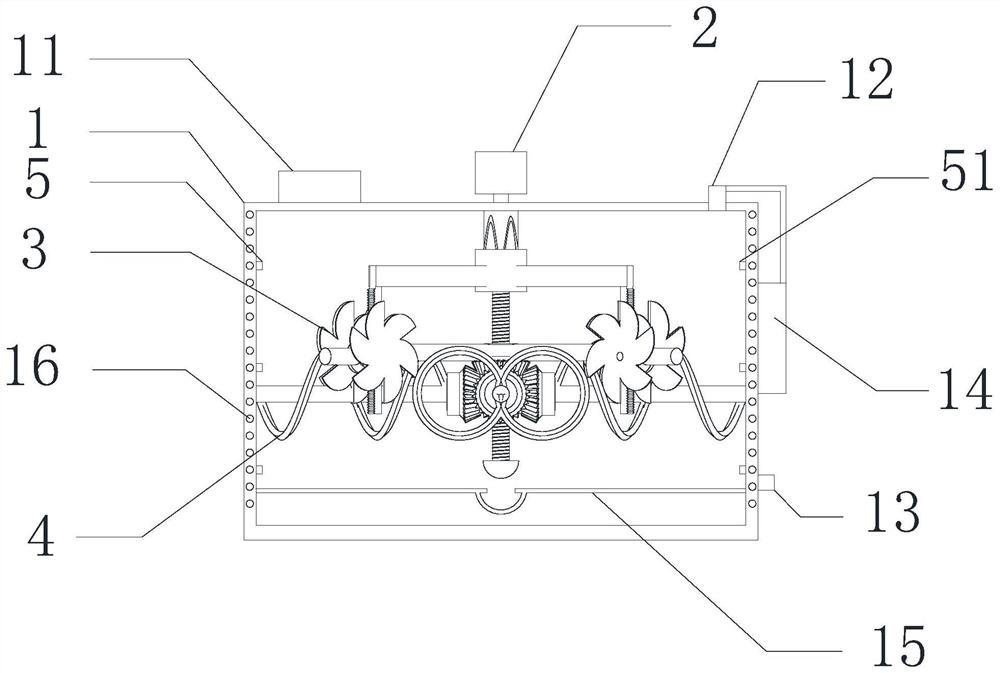

[0049] Example 1: Take 40 parts of A component, 20 parts of B component, and 1 part of C component in three batches and add them to the stirring and defoaming device in turn, and stir and mix at a speed of 2800r / min for 25 minutes; then take 0.2 parts of F component Add it into the stirring and defoaming device, continue to stir and mix at a speed of 2800r / min for 20min, finally add 1 part of D and 1 part of E in two batches, stir and mix at a speed of 2800r / min for 15min, and keep the stirring and defoaming device at a speed of 1200r / min Min to stir, control the vacuum in the stirring and defoaming device to -0.1Mpa, defoam the mixed components for 35min, keep the temperature at 20°C, keep the humidity at 40%, and fill the glue until it is black in a dark environment. light hose.

Embodiment 2

[0050] Example 2: Take 45 parts of A component, 22 parts of B component, and 1.5 parts of C component in three batches and add them to the stirring and defoaming device in turn, and stir and mix at a speed of 2800r / min for 25 minutes; then take 0.4 parts of F component Add it into the stirring and defoaming device, continue to stir and mix at a speed of 2800r / min for 20min, finally add 1.3 parts of D and 2 parts of E in two batches, stir and mix at a speed of 2800r / min for 15min, and keep the stirring and defoaming device at a speed of 1200r / min Min to stir, control the vacuum in the stirring and defoaming device to -0.1Mpa, defoam the mixed components for 35min, keep the temperature at 20°C, keep the humidity at 40%, and fill the glue until it is black in a dark environment. light hose.

Embodiment 3

[0051] Example 3: Take 50 parts of A component, 24 parts of B component, and 2 parts of C component in three batches and add them to the stirring and defoaming device in turn, and stir and mix at a speed of 2800r / min for 25 minutes; then take 0.6 parts of F component Add it into the stirring and defoaming device, continue to stir and mix at a speed of 2800r / min for 20min, finally add 1.6 parts of D and 3 parts of E in two batches, stir and mix at a speed of 2800r / min for 15min, and keep the stirring and degassing device at a speed of 1200r / min Min to stir, control the vacuum in the stirring and defoaming device to -0.1Mpa, defoam the mixed components for 35min, keep the temperature at 20°C, keep the humidity at 40%, and fill the glue until it is black in a dark environment. light hose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com