Crystal grinding control method and system based on open-loop cross coupling iterative learning

A cross-coupling and iterative learning technology, applied in the field of servo control, can solve the problems that cannot fully adapt to the servo system of the high dynamic performance speed control system, and achieve the effect of improving the contour tracking ability, reducing the contour error and improving the tracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

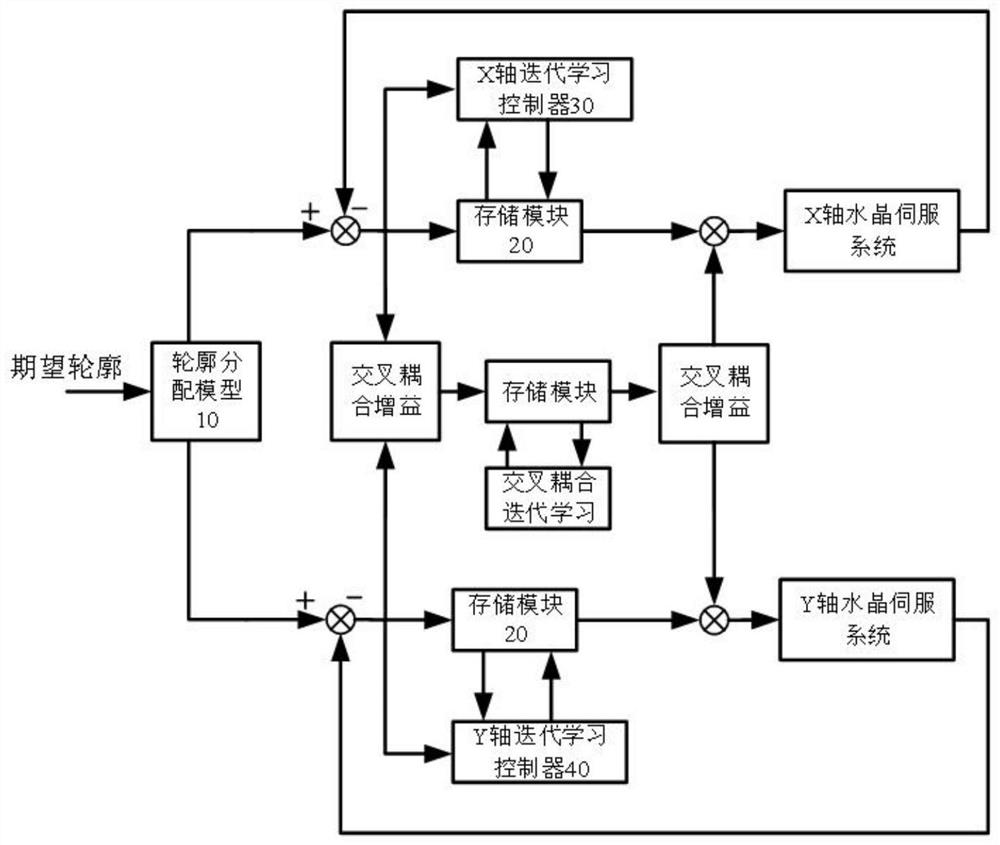

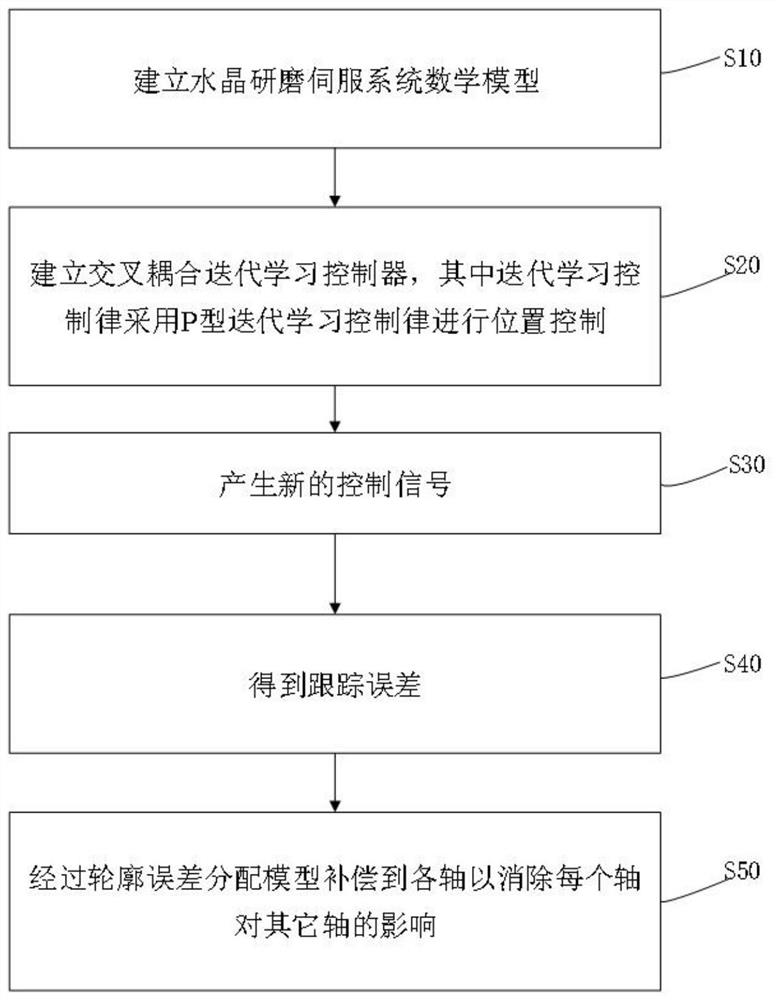

[0054] For the above crystal grinding control system based on open-loop cross-coupling iterative learning, see figure 2 , the technical solution of the present invention which is an embodiment of the present invention is a contour grinding algorithm based on discrete cross-coupling iterative learning, comprising the following steps:

[0055] S10, establishing a mathematical model of the crystal grinding servo system;

[0056] S20, establishing a cross-coupled iterative learning controller, wherein the iterative learning control law uses a P-type iterative learning control law for position control;

[0057] S30, generating a new control signal;

[0058] S40, obtaining a tracking error;

[0059] S50, distribute model compensation to each axis through the contour error to eliminate the influence of each axis on other axes.

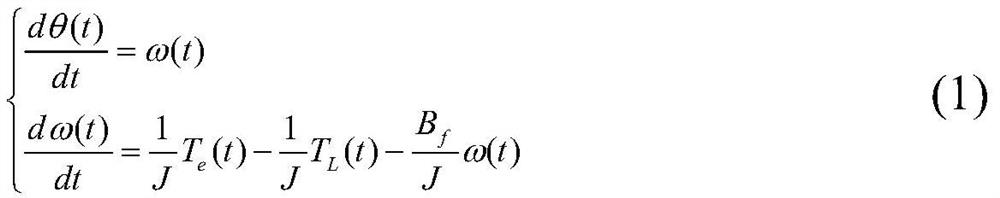

[0060] In specific implementation, S10 includes the following steps:

[0061] S11, using the method of vector control can make the permanent magnet sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com