Machining device for hydraulic cylinder body

A processing device and hydraulic cylinder technology, which is applied in the field of hydraulic cylinder processing, can solve the problems of low processing efficiency and time-consuming hydraulic cylinder block processing, and achieve the effect of convenient operation and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-6 The application is described in further detail.

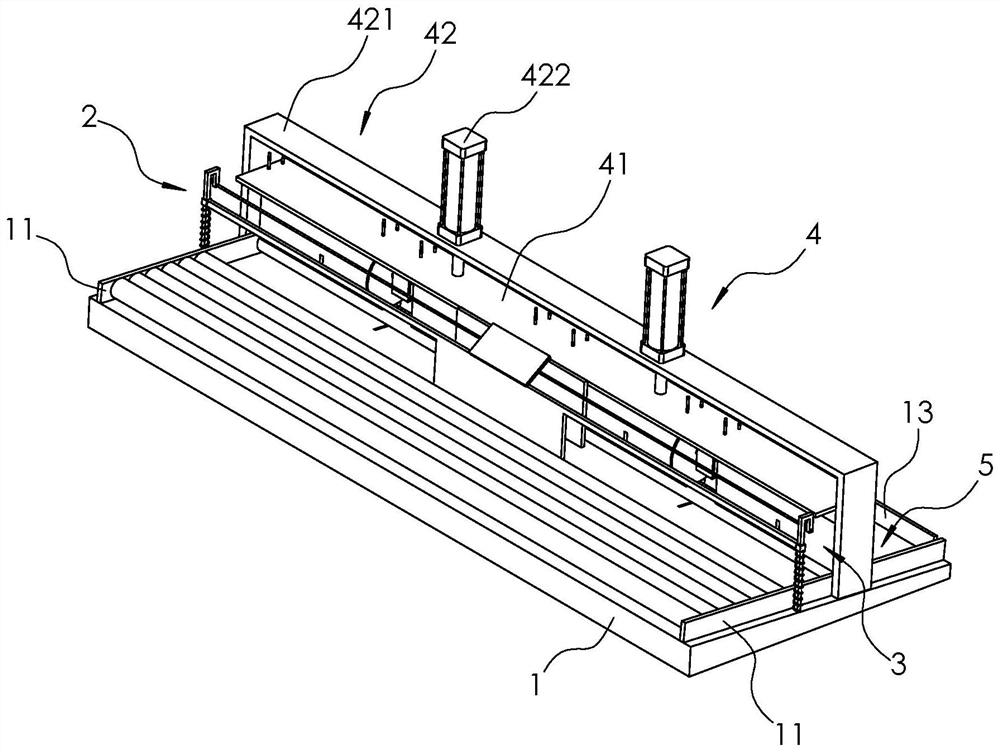

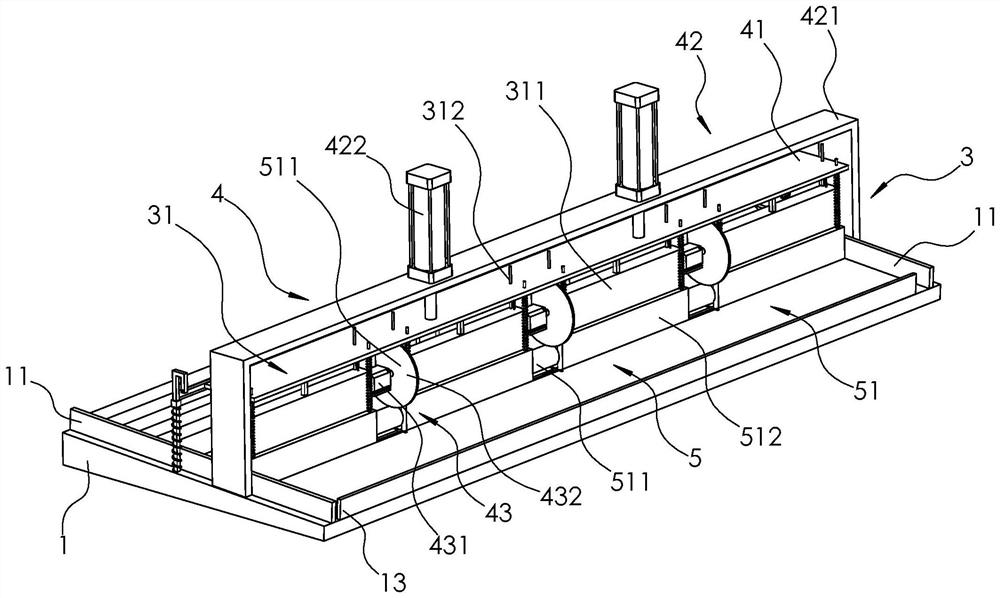

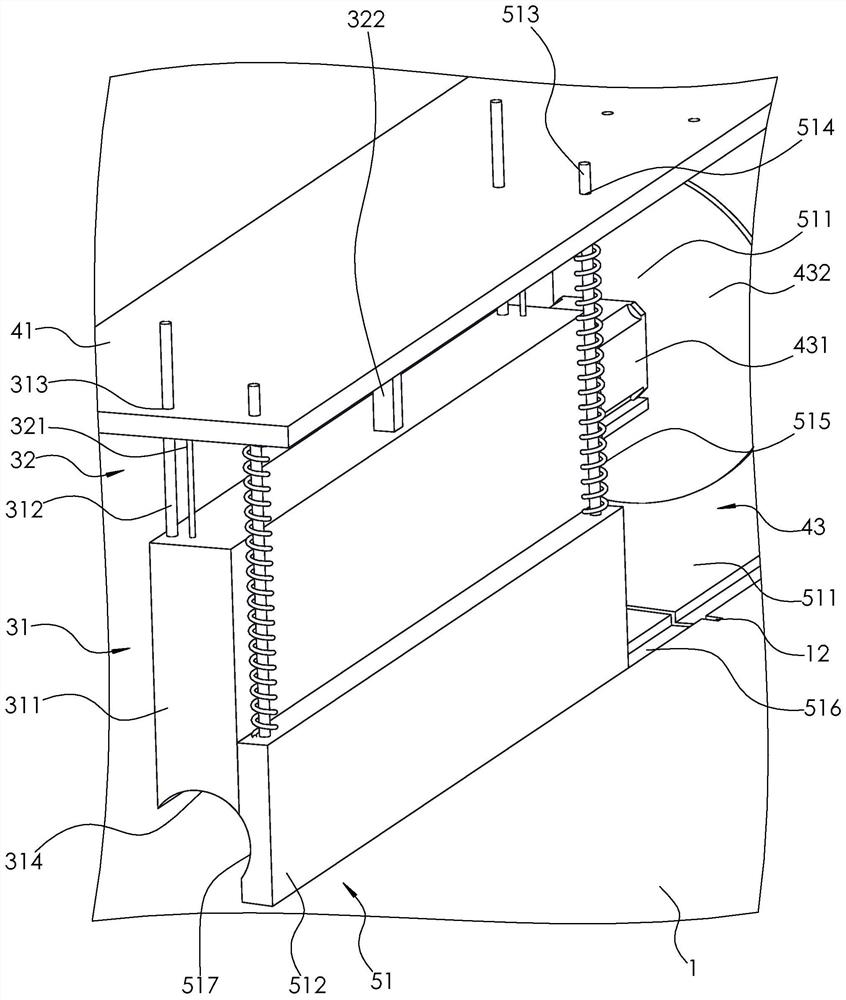

[0047] The embodiment of the present application discloses a processing device for a cylinder body of a hydraulic cylinder. Such as figure 1 and figure 2 As shown, a processing device for a cylinder body of a hydraulic cylinder includes a base 1 , a stopper mechanism 2 arranged above the base 1 , a pressing mechanism 3 , a sawing mechanism 4 and a feeding mechanism 5 . The blocking assembly realizes the preparation of multiple steel pipes, the pressing mechanism 3 is used to compress the steel pipes to be processed, the sawing mechanism 4 is used to saw the compressed steel pipes, and the unloading mechanism 5 is used to complete the sawing steel pipe blanking.

[0048] The upper surface of the base 1 is inclined, and the steel pipe can roll down on the upper surface of the base 1. The stopper mechanism 2, the sawing mechanism 4 and the blanking mechanism 5 are sequentially arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com